Photochromic fiber

A photochromic and photochromic technology, applied in the chemical characteristics of fibers, conjugated synthetic polymer rayon, textiles and papermaking, etc., can solve the problems of affecting light, judgment time, poor shading performance, etc., and improve thermal insulation. performance, the effect of ensuring the occlusion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of polyethylene terephthalate modified photochromic agent comprises the following steps:

[0031] 1) Add terephthalic acid and ethylene glycol into the reactor, heat the reactor and stir it to carry out esterification reaction, generate esterification product, and cool to solid; the reaction temperature is 180-220°C; the reaction time is 1 -4 hours.

[0032] 2) Grinding the esterification product into powder to obtain the esterification product powder;

[0033] 3) After fully mixing the esterification product powder and the organic color-changing agent, a vacuum polycondensation reaction is carried out to prepare a polyethylene terephthalate-modified photochromic agent. When the vacuum polycondensation reaction is carried out, the vacuum is kept stable in this application, and the polycondensation conditions of low vacuum in the early stage and high vacuum in the late stage cannot be used in some existing technologies.

[0034] In this applicati...

Embodiment 1

[0037] A photochromic fiber comprising at least a photochromic fiber;

[0038] Photochromic fiber by weight, it consists of:

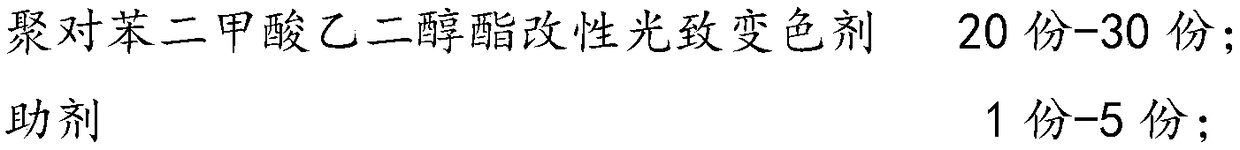

[0039]

[0040] The photochromic agent is an organic photochromic agent.

[0041] In the polyethylene terephthalate modified photochromic agent, the photochromic agent accounts for 0.1% of the total weight of the polyethylene terephthalate modified photochromic agent.

[0042] The organic photochromic agent comprises a composition of spiropyran and azobenzene, wherein the mass ratio of spiropyran and azobenzene is 1:1.

[0043] The auxiliary agent includes one or more combinations of oxidizing agent, compatibilizer, antiaging agent and light stabilizer.

[0044] The preparation method of polyethylene terephthalate modified photochromic agent comprises the following steps:

[0045] 1) Add terephthalic acid and ethylene glycol to the reactor, the reaction temperature is 180°C; the reaction time is 1 hour, the reactor is heated and stirred to carry ...

Embodiment 2

[0049] A photochromic fiber comprising at least a photochromic fiber;

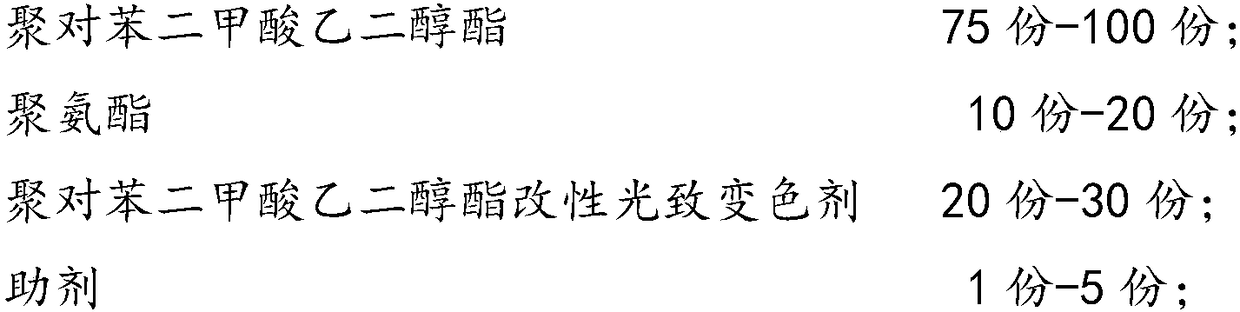

[0050] Photochromic fiber by weight, it consists of:

[0051]

[0052] The photochromic agent is an organic photochromic agent.

[0053] In the polyethylene terephthalate modified photochromic agent, the photochromic agent accounts for 5% of the total weight of the polyethylene terephthalate modified photochromic agent.

[0054] The organic photochromic agent comprises a composition of spiropyran and azobenzene, wherein the mass ratio of spiropyran and azobenzene is 1:1.

[0055] The auxiliary agent includes one or more combinations of oxidizing agent, compatibilizer, antiaging agent and light stabilizer.

[0056] The preparation method of polyethylene terephthalate modified photochromic agent comprises the following steps:

[0057] 1) Add terephthalic acid and ethylene glycol to the reactor, the reaction temperature is 220°C; the reaction time is 4 hours, the reactor is heated and stirred, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com