A preparation method of micro-nano-scale oriented fibers with controllable stiffness

A micro-nano, oriented technology, used in fiber processing, filament/thread forming, textile and papermaking, etc., can solve problems such as chemical composition changes, and achieve the effect of expanding scope and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) At room temperature, 0.684g PLCL (the copolymerization ratio of lactic acid and caprolactone is 50:50, the viscosity is 2.5dl / g, purchased from Jinan Daigang Biomaterials Co., Ltd.), 0.036g ultra-high molecular weight PEO ( Molecular weight>5.0×10 6 Da (purchased from Alfa Aesar, UK) was dissolved in 6mL of hexafluoroisopropanol (purchased from Shanghai Darui Fine Chemicals Co., Ltd.), and stirred for 12 hours to obtain PLCL- PEO shell solution.

[0049] (2) 0.57g PLLA (molecular weight of polylactic acid is 100,000Da, purchased from Jinan Daigang Biomaterials Co., Ltd.), 0.03g ultra-high molecular weight PEO (molecular weight>5.0×10 6 Da (purchased from Alfa Aesar, UK) was dissolved in 6 mL of hexafluoroisopropanol (purchased from Shanghai Darui Fine Chemicals Co., Ltd.), and stirred for 12 hours to obtain PLLA- PEO core solution.

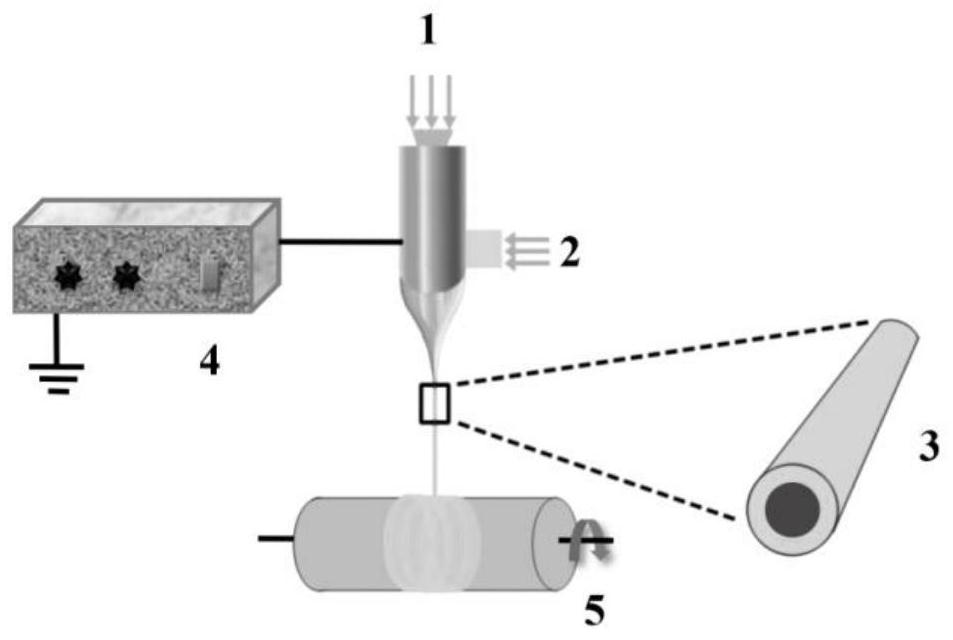

[0050] (3) The shell solution and the core solution prepared above are respectively placed in separate syringes, such as figure 1...

Embodiment 2

[0057] The injection rate of PLCL shell solution was 0.35mL / h and the injection rate of PLLA core solution was 0.15mL / h during stable jet coaxial electrospinning, and the rest were the same as in Example 1 to obtain PLCL / PLLA micro-nano-scale oriented fibers.

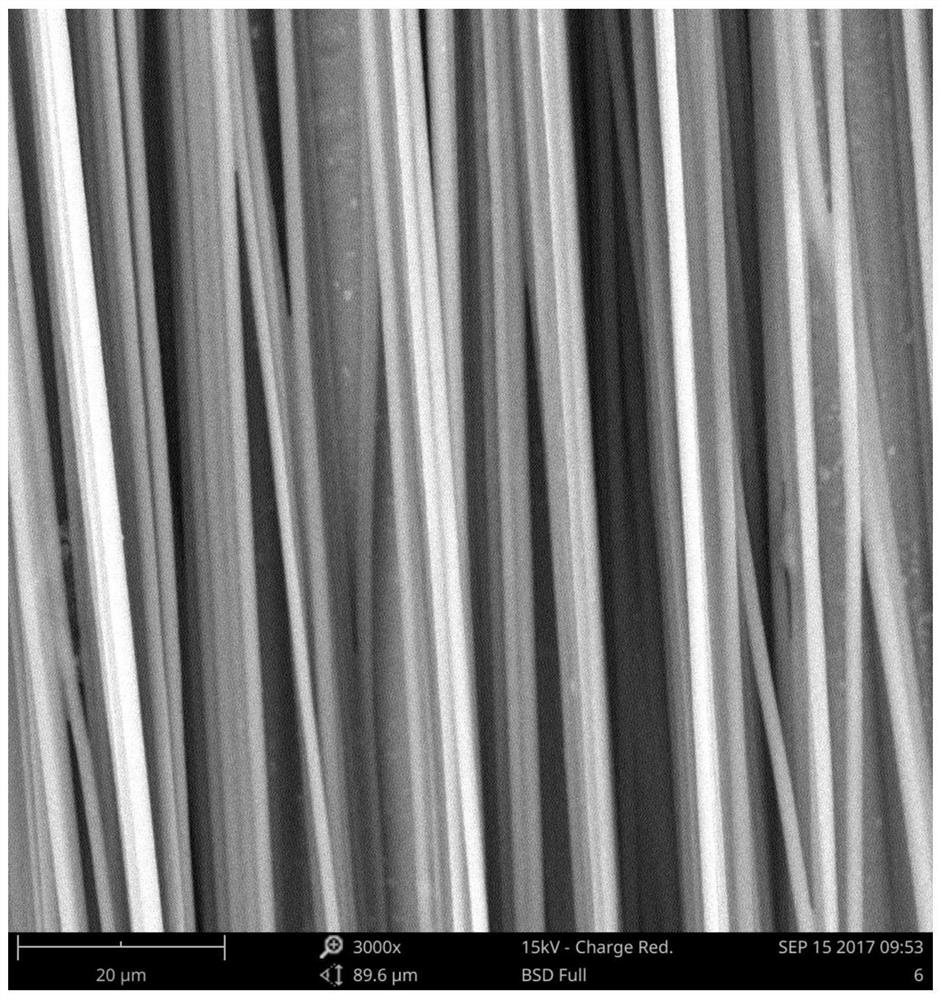

[0058] Figure 5 It shows that the PLCL / PLLA micro-nano-scale oriented fiber has a highly oriented structure, and the fiber diameter is 1.40±0.16 μm, which is not significantly different from the fiber diameter obtained in Example 1, that is, the fiber diameter does not change significantly after the shell-core structure is adjusted. .

[0059] Image 6 It shows that PLCL / PLLA micro-nano-scale oriented fiber has obvious shell-core structure, and the chemical composition of the fiber surface does not change, which is still PLCL. The thickness of PLCL shell layer is measured to be 0.35±0.06 μm.

[0060] Figure 11 It shows that the fiber obtained in this example has a higher degree of orientation, and the degree of ori...

Embodiment 3

[0064] The injection rate of PLCL shell solution was 0.2mL / h, and the injection rate of PLLA core solution was 0.3mL / h during steady-jet coaxial electrospinning. The rest were the same as in Example 1 to obtain PLCL / PLLA micro-nano-scale oriented fibers.

[0065] Figure 7 It shows that the PLCL / PLLA micro-nano-scale oriented fiber has a highly oriented structure, and the fiber diameter is 1.34±0.20 μm, which is not significantly different from the fiber diameter obtained in Example 1-2, that is, the fiber diameter does not significantly change after the shell-core structure is adjusted. Sexual changes.

[0066] Figure 8 It shows that PLCL / PLLA micro-nano-scale oriented fiber has obvious shell-core structure, and the chemical composition of the fiber surface does not change, which is still PLCL. The thickness of PLCL shell layer is measured to be 0.16±0.02μm.

[0067] Figure 11 It shows that the fiber obtained in this example has a higher degree of orientation, and the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com