Warping creel of automatic weaving machine for weaving and molding carbon fiber three-dimensional fabric

A technology of three-dimensional fabrics and carbon fibers, which is applied in the direction of braids, textiles, and papermaking, to achieve the effects of strong practicability, cost reduction, and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in combination with specific embodiments.

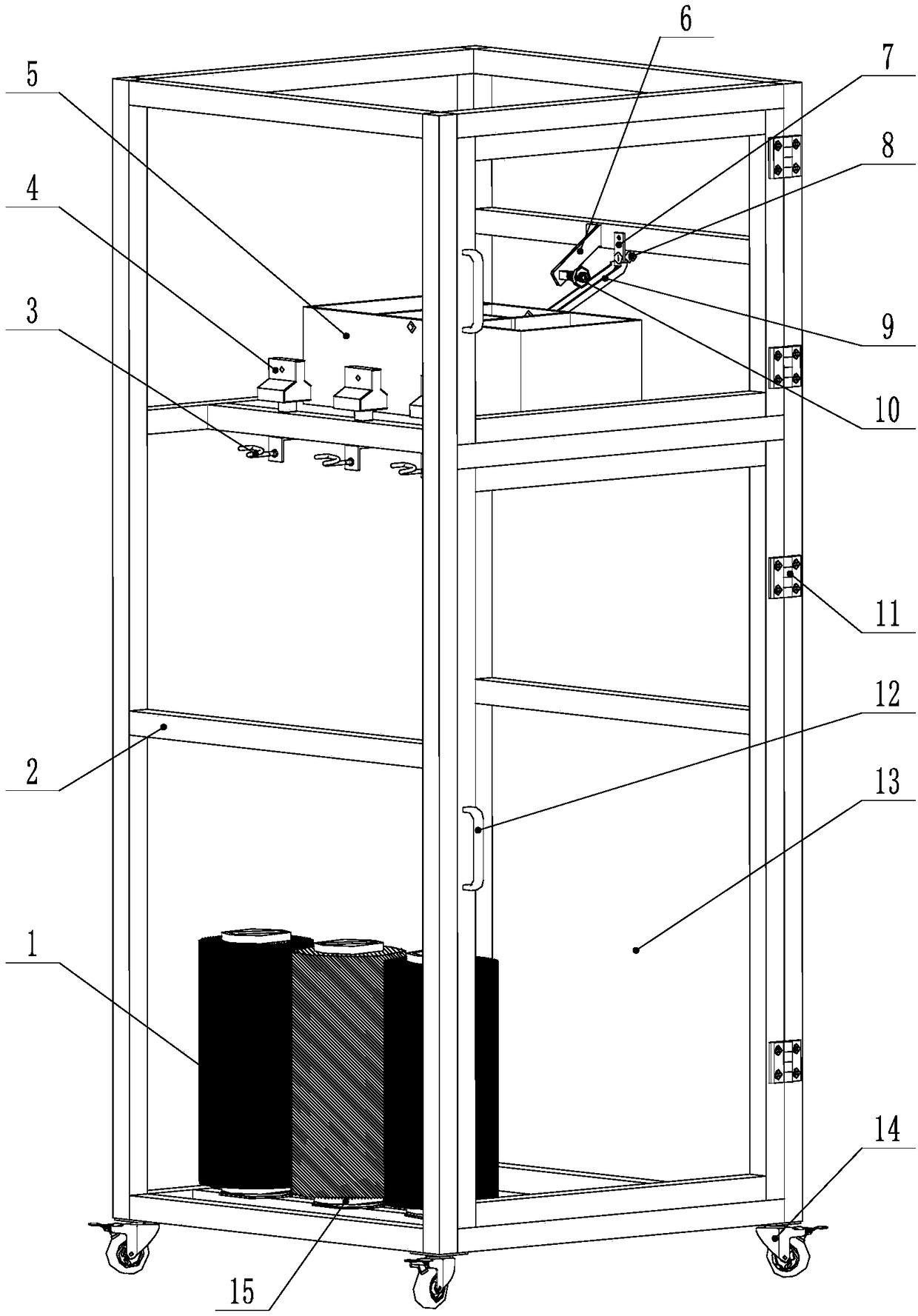

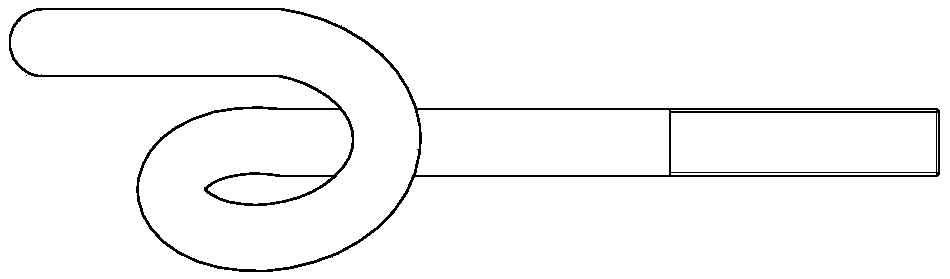

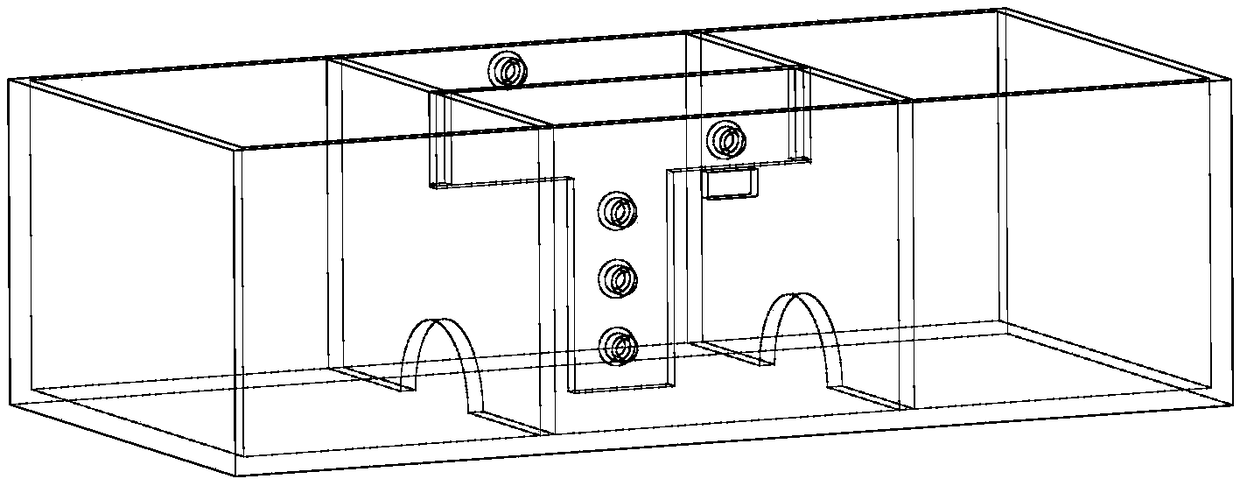

[0037] Such as Figure 1 to Figure 7 As shown, a creel for weaving and forming a carbon fiber three-dimensional fabric automatic knitting machine includes a frame body 2, a yarn guide hook 3, a weft yarn detector 4, an auxiliary agent tank 5, a cantilever plate 6, a wire plate 7, a porcelain ring 8, and a return flow tank 9. Tension regulator 10 and yarn withdrawal seat 15. The frame body 2 is connected by aluminum profiles. There are upper side door and lower side door installed on one side of the frame body. The upper side door can be used for yarn threading and additives, and the lower side door is used for When replacing the carbon fiber bobbin, a fully transparent acrylic plate 13 is installed around the frame body and in the upper and lower aluminum profile frames to observe the unwinding of the weft yarn and the amount of additives used. Four lockable panel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com