Continuous pressure measurement test system for model surface based on pressure scanning valve

A test system and surface pressure technology, applied in the direction of aerodynamic test, measuring device, machine/structural component test, etc., can solve the problems of low static test efficiency and less information of test results, and achieve complete and rich aerodynamic data, Effects of reduced test cost and accurate aerodynamic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

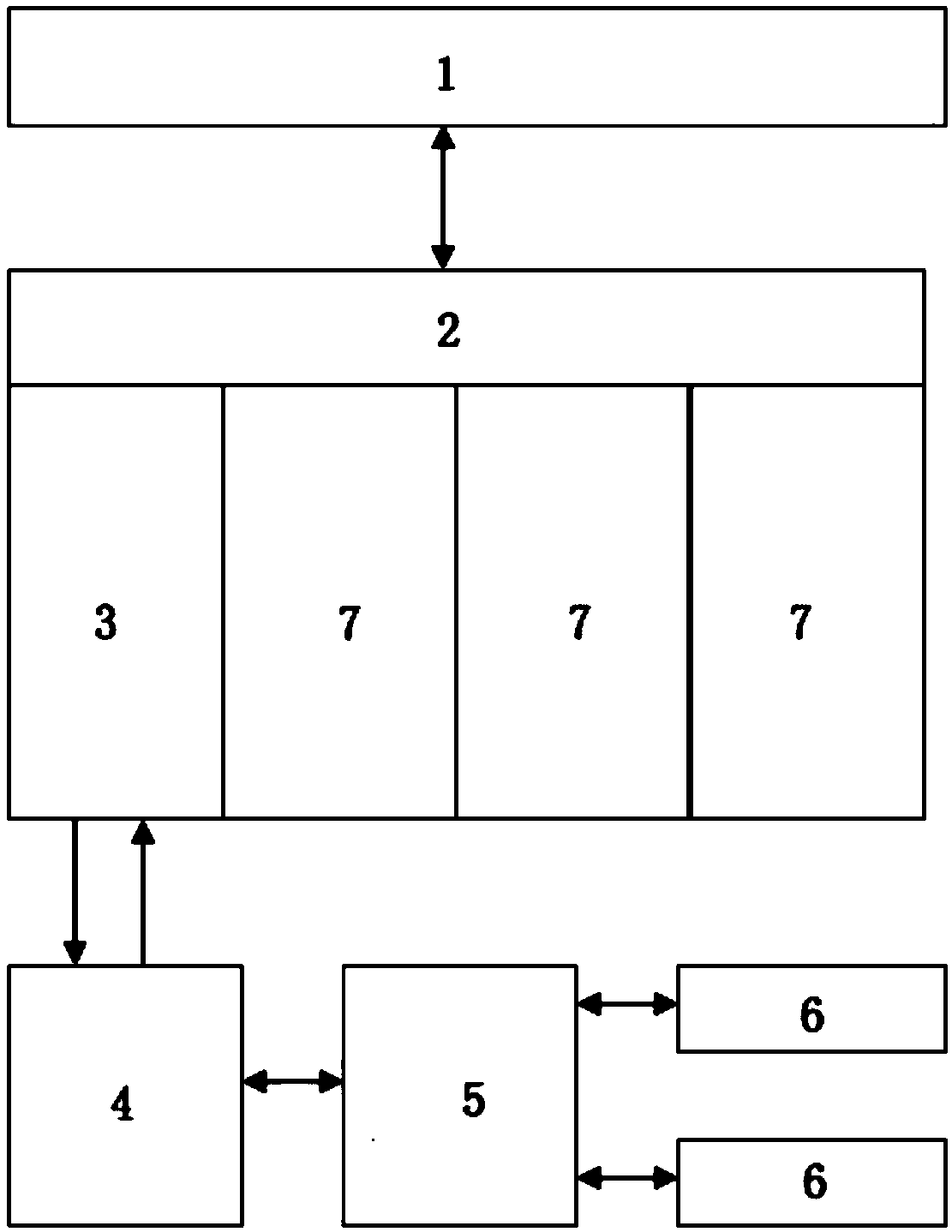

[0011] Such as figure 1 As shown, a model surface pressure continuous measurement test system based on pressure scanning valve, including the main control machine 1, and two sets of pressure scanning valve 6, system processor 2, optical fiber interface unit 3, scanning valve digital interface unit 4, scanning The valve interface unit 5 and three sets of pressure calibration units 7, the main control machine 1 communicates with the system processor 2 through Ethernet, the system processor 2 is connected with the optical fiber interface unit 3 and the three sets of pressure calibration units 7 respectively, and the optical fiber interface unit 3 communicate with the digital interface unit 4 of the scanning valve through optical fiber, and the digital interface unit 4 of the scanning valve is connected with two sets of pressure scanning valves 6 through the interface unit 5 of the scanning valve.

Embodiment 2

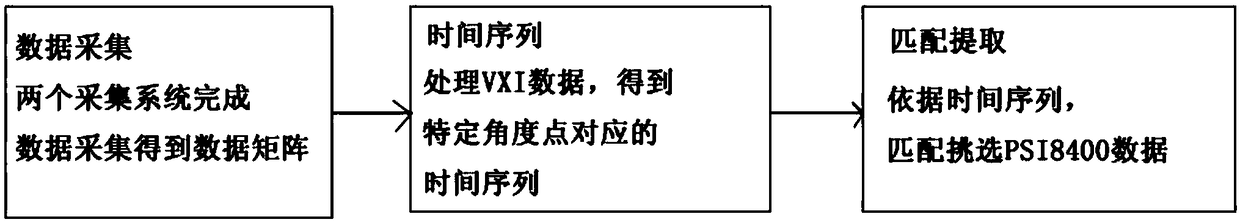

[0013] The above-mentioned test method of simultaneous pressure measurement and force measurement data acquisition on the model surface is adopted, and the VXI data acquisition system is also used. The two systems are triggered by triggering and start acquisition at their respective sampling rates at the same time. The VXI data acquisition system detects in real time The signal change of the angle acquisition channel, when the value of the angle channel signal enters the corresponding value of the test angle, record the time from the moment of the corresponding angle to the moment of sampling, and find the model surface pressure continuous measurement test system at the corresponding moment according to this time The measured value is stored and circulated until the pressure collection of all test angles is completed, and the test of this train is completed.

[0014] Within the range of the attitude angle required to be measured, according to the continuous change of the attitu...

Embodiment 3

[0016] Taking the test angle of 0°-20° as an example, after the test wind speed is stable, the angle mechanism starts to run at a constant speed from 0° to 20°, the collection frequency of the VXI data acquisition system is 125Hz, and the measuring point frequency of the scanning valve is 20Hz, and the mechanism starts to run Finally, the main control computer triggers the two sets of systems to start collecting at the same time according to their respective sampling rates. The VXI data acquisition system detects the signal change of the angle acquisition channel in real time. When the value of the angle channel signal enters the corresponding value of the test angle, the VXI data While the acquisition system records the force measurement data of the balance corresponding to the current angle channel, it also records the time from the moment of the corresponding angle to the moment of sampling. The scanning valve pressure acquisition system finds the pressure measurement at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com