Array substrate, display panel and display device

An array substrate, the same technology, applied in the display field, can solve the problems of cumbersome production process, many film layers, unfavorable practical application of array substrate, etc., and achieve the effect of simplifying the production process and reducing the film layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

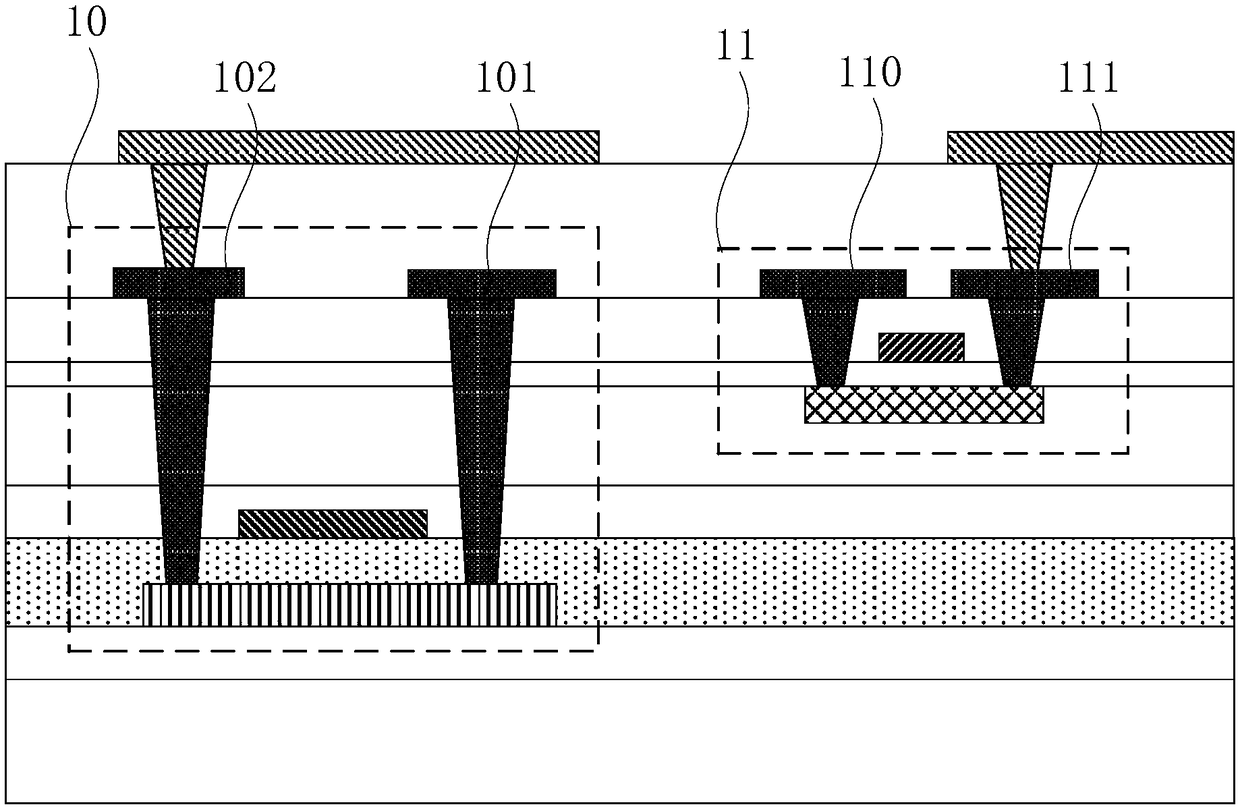

[0037] As mentioned in the background art, the low-temperature polysilicon thin film transistors and the oxide thin film transistors in the existing array substrates share fewer film layers, resulting in more film layers on the array substrate and complicated manufacturing processes. Such as figure 1 as shown, figure 1 It is a schematic cross-sectional structure diagram of an existing array substrate. Even though the source 101 and the drain 102 of the low-temperature polysilicon thin film transistor 10 are arranged on the same layer as the source 110 and the drain 111 of the oxide thin film transistor 11, the array substrate The film layer is still more.

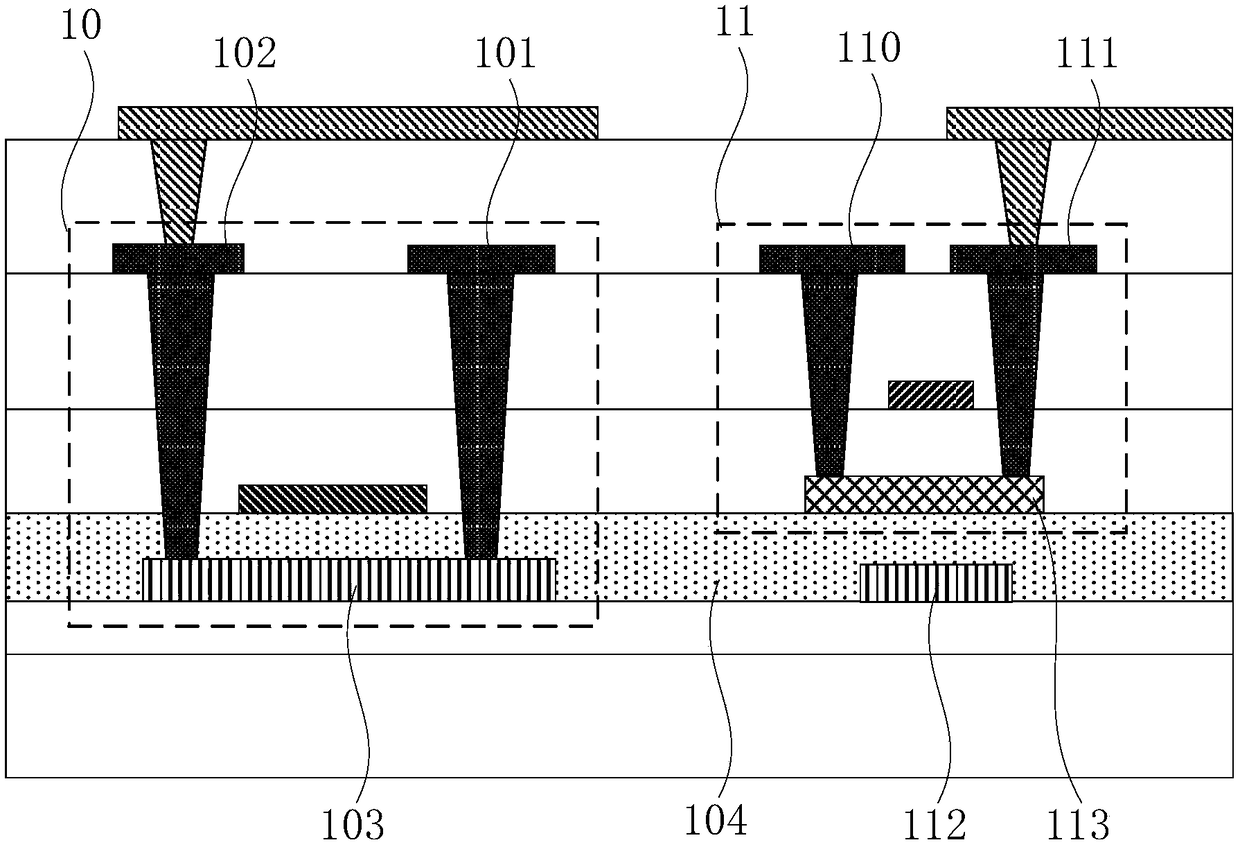

[0038] Such as figure 2 as shown, figure 2 It is a schematic cross-sectional structure diagram of an existing array substrate. In order to minimize the film layer of the array substrate, the inventors set the active layer 103 of the low-temperature polysilicon thin film transistor and the bottom gate 112 of the oxide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com