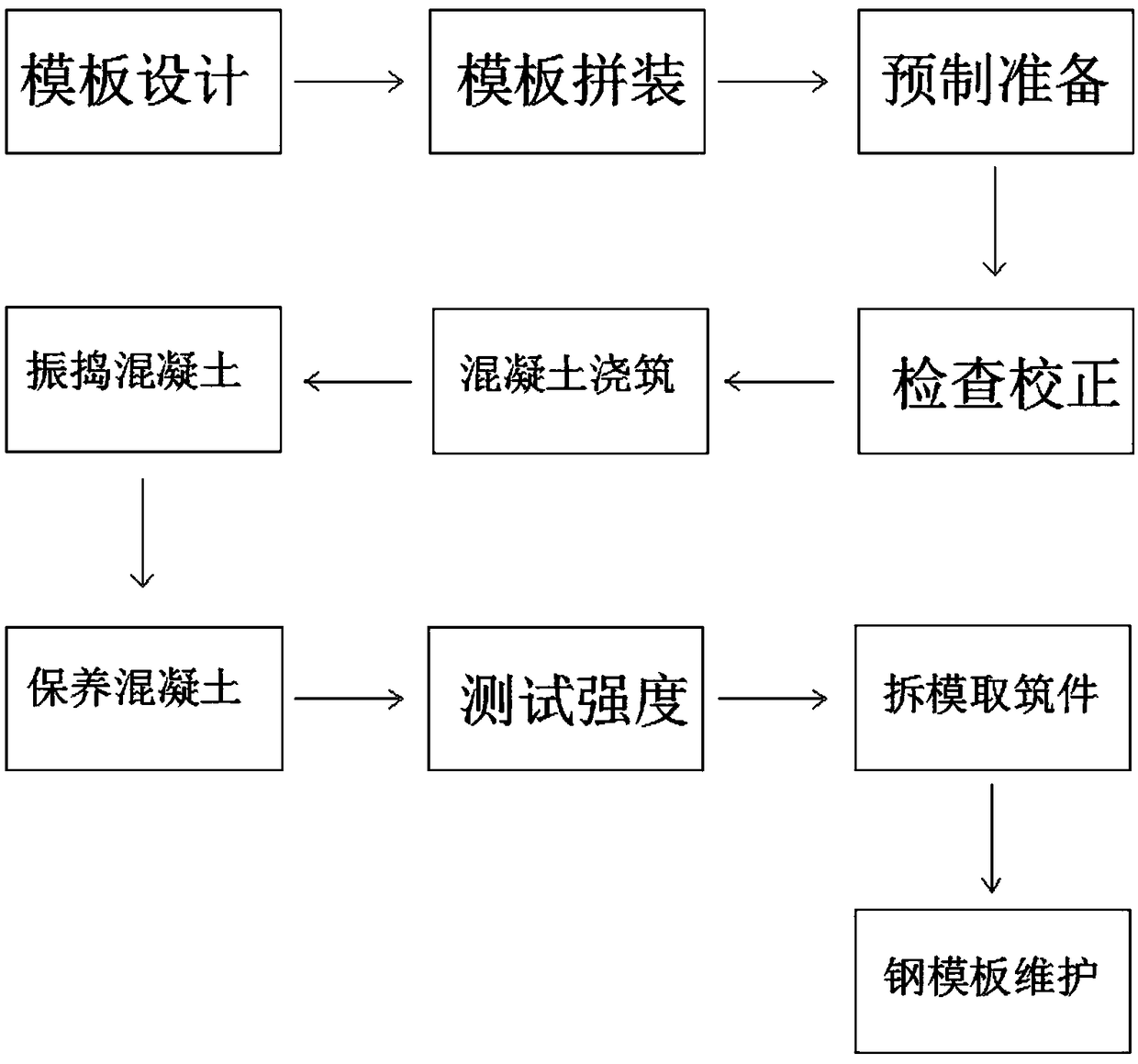

Construction process of concrete steel formwork

A construction technology and steel formwork technology, which is applied in the direction of manufacturing tools, mold separation devices, ceramic molding machines, etc., can solve the problems of unimproved concrete fixing and form removal process, easy cracking and damage of concrete building parts, pockmarked concrete surface building parts, etc. problems, to achieve the effect of improving the molding quality and strength, not easy to rust and oxidize, and the surface is smooth and beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, objectives, and effects of the invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0037] Construction technology of a concrete steel formwork

[0038] Step 1: Template Design

[0039] According to the type and characteristics of the project structure and on-site construction conditions, design the steel formwork, determine the plane layout of the steel formwork, the specifications, quantity, and arrangement size of the vertical and horizontal keels, the type and spacing of column hoops, the distance between beam and slab supports, formwork assembly form and connection Large-scale joints, the formwork assembly form is one of in-place assembly or prefabricated assembly, and check the strength, stiffness and stability of the steel formwork support, and draw a full set of steel formwork design drawings, including formwork plan, block diagram, assembly drawing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com