Cage type foldable multi-rotor heavy-duty large unmanned aerial vehicle

A technology of unmanned aerial vehicles and multi-rotors, which is applied in the aviation field, can solve the problems of short flight time, low load capacity, and the inability to carry out long-term flight with heavy load, and achieve long flight time, large load capacity, and easy parking and transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

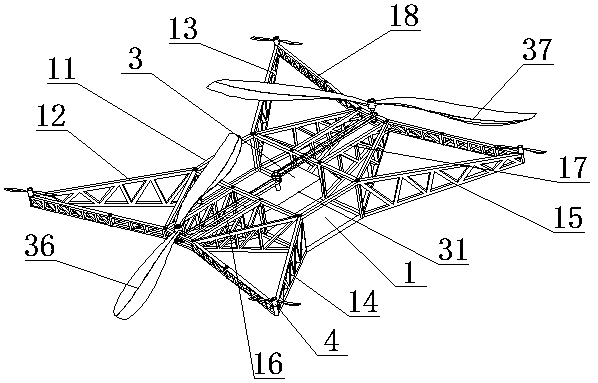

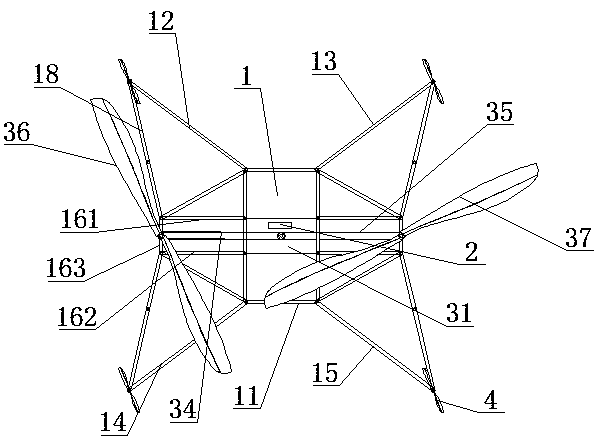

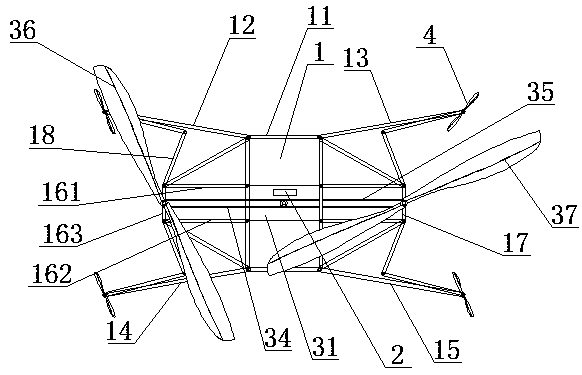

[0018] The present invention is described in detail below in conjunction with the accompanying drawings: a cage-type foldable multi-rotor heavy-duty large-scale unmanned aerial vehicle, comprising a cage body 1, a flight control device 2, a lift device 3, and an attitude control device 4; a cage body 1 Comprising a square frame 11, a left front movable arm 12, a right front movable arm 13, a left rear movable arm 14 and a right rear movable arm 15; a left support frame 16 and a right support frame 17 extend from the left and right sides of the square frame 11 middle part; the left front movable arm 12, the roots of four of the front right movable arm 13, the left rear movable arm 14 and the right rear movable arm 15 are loosely installed on the four end angles of the cage body 1 respectively; The positions are all connected with the left support frame 16 by the folding frame 18; the tip positions of the right front movable arm 13 and the right rear movable arm 15 are all connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com