Real-time monitoring device for underwater pig operation based on optical fiber detection

A real-time monitoring and pigging technology, applied in the direction of cleaning equipment, measurement, wellbore/well components, etc., can solve the problem of inability to accurately judge whether to pass a specific key road section, unable to monitor the real-time position and operating status of the pipe pig, and unable to real-time Detect problems such as pig speed and position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

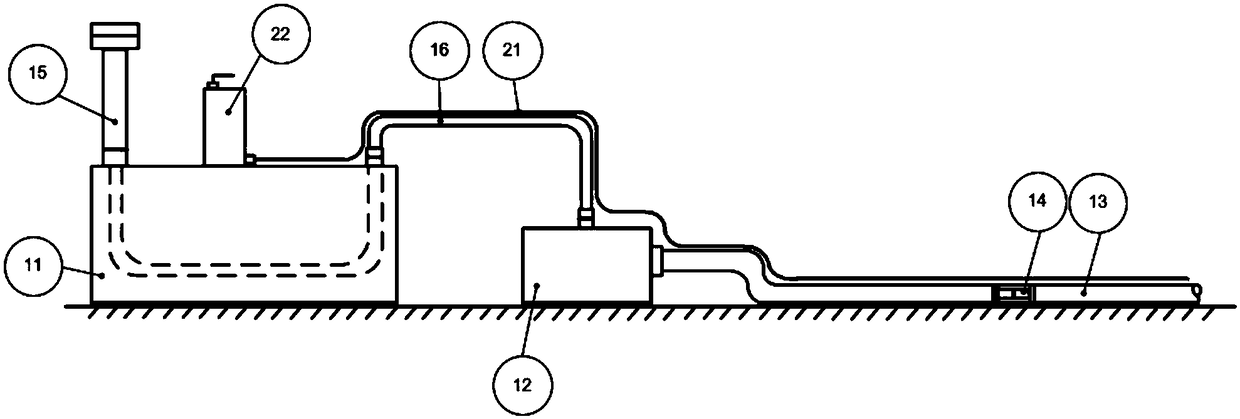

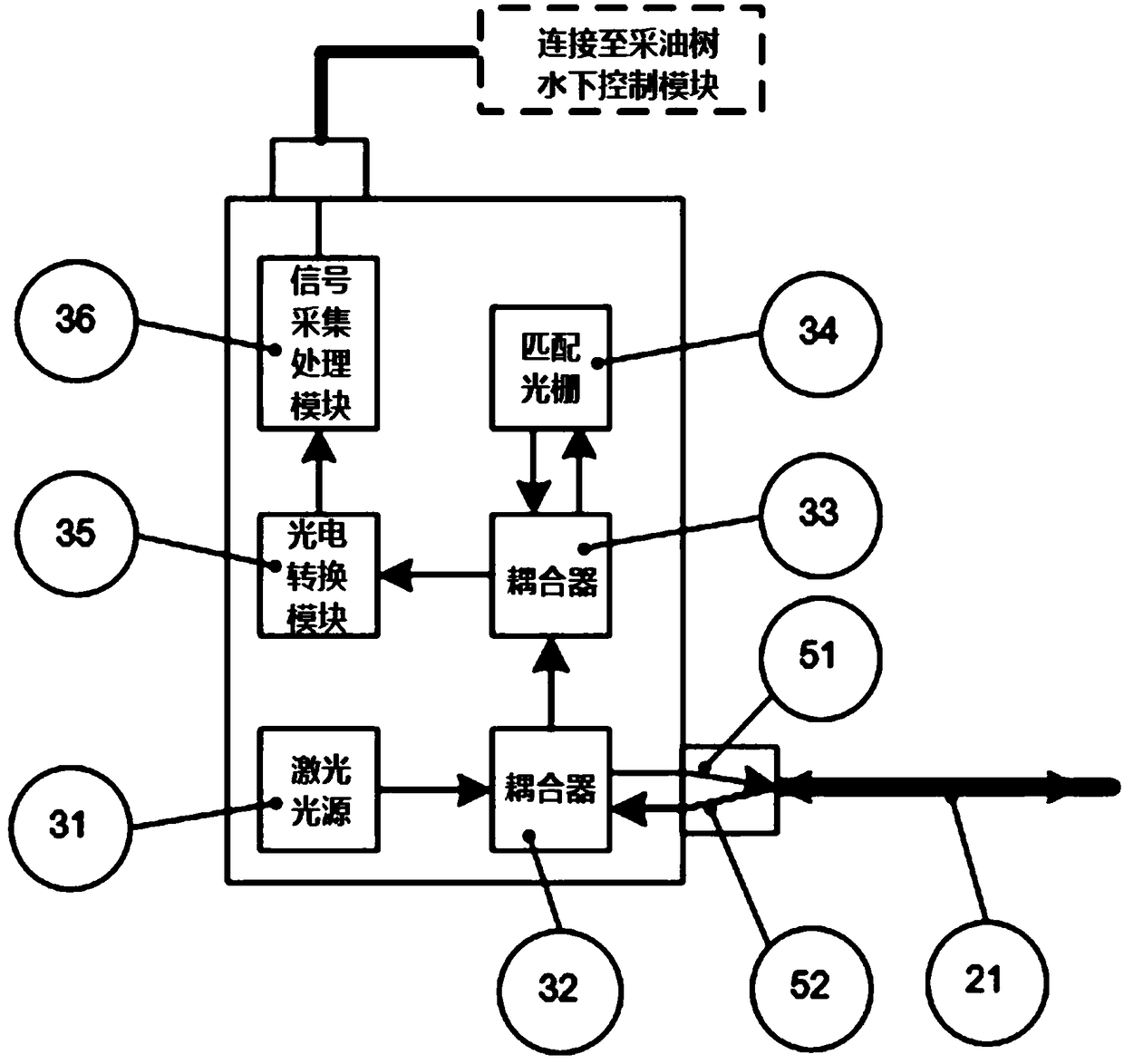

[0016] Such as figure 1 , figure 2 As shown, the underwater pig operation real-time monitoring device 22 of the present invention is installed on the seabed central manifold 11 . The oil and gas produced by the oil and gas wells are collected into the subsea central manifold 11, and are transported to the offshore oil storage platform or offshore processing facility through the steel jumper 16, the pipeline terminal 12 and the subsea oil pipeline 13. The bottom of the pig operation real-time monitoring device 22 is provided with an optical fiber interface, and is connected to the optical fiber grating 21 . The fiber grating 21 surrounds and covers the surface of the jumper pipe 16 and the submarine oil pipeline 13, and is covered and fixed with a waterproof adhesive tape.

[0017] During the pigging operation, the offshore platform lifts the pig launching tube 15 into the water and connects it to the subsea manifold 11, and launches the pig 14 to start the pigging operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com