Filler tube for fuel tank

A technology for filling pipes and fuel tanks, which is applied in the layout, application, household components, etc. combined with the fuel supply of internal combustion engines, can solve problems such as damage to the quality of welded joints, increased fuel diffusion, and increased overall emission values. Low equipment and energy consumption, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

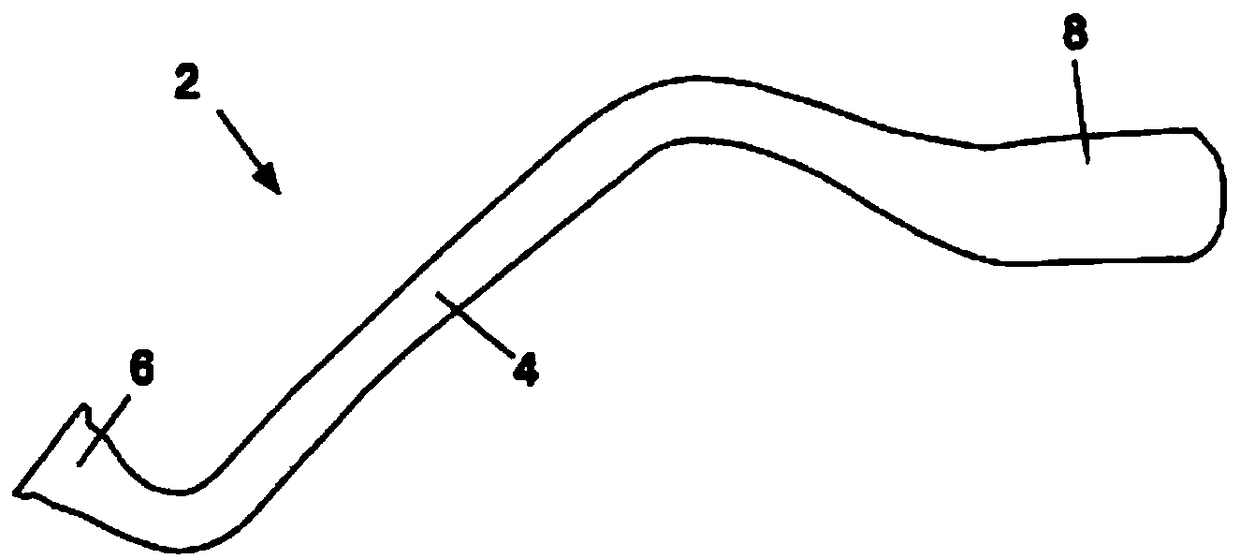

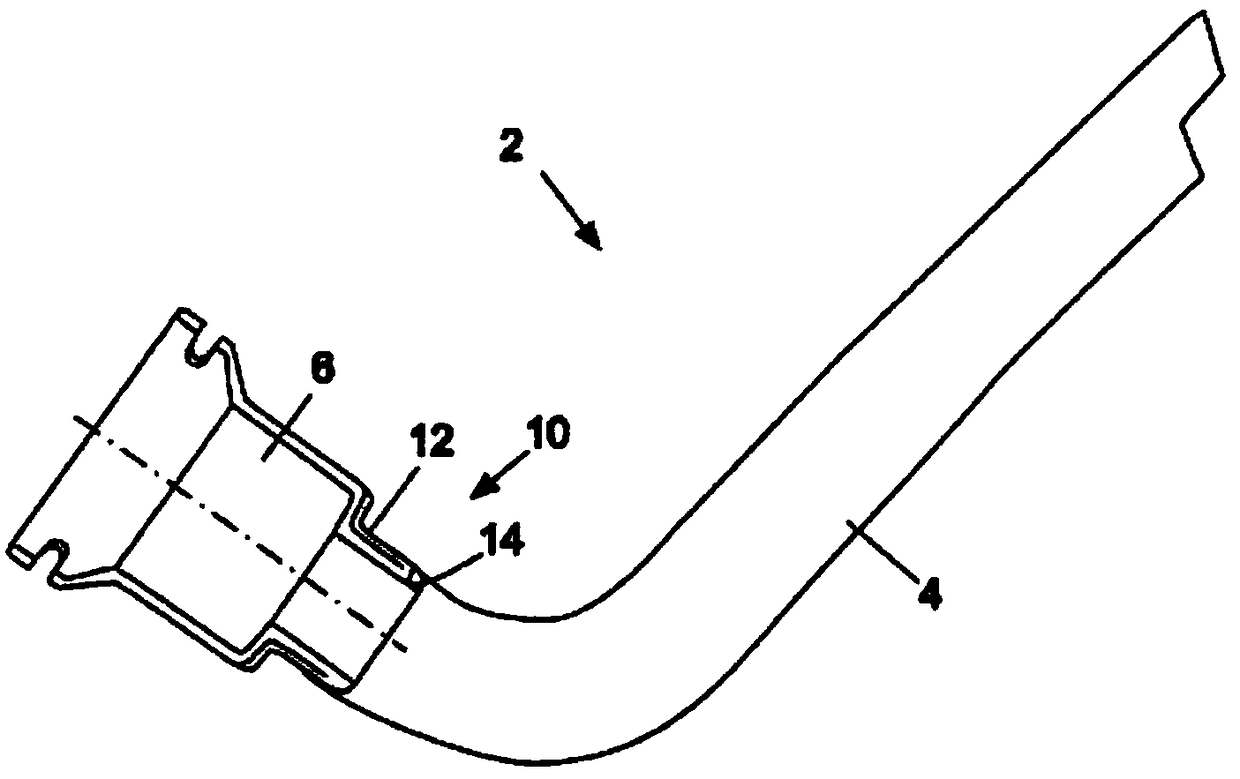

[0096] Figure 1A A filling tube 2 for a fuel tank (not shown) is shown. The filling tube 2 has a tube part 4 made of plastic. In the present invention, the pipe part 4 has been made of thermoplastic material. The tube part 4 can be made of plastic in a single layer. The tube part 4 can alternatively be made in multiple layers from a coextruded hose material which is molded in a blow mold by applying internal pressure. The tube part 4 can be molded to bend in at least two spatial directions by means of a blow molding process.

[0097] The filling tube 2 has a tubular adapter 6 which is connected to the tube part 4 . The adapter 6 is used to couple the filling pipe 2 to the fuel tank. At the end 8 of the filling tube 2 opposite the adapter 6 , the tube part 4 has an enlarged diameter, wherein said enlarged end 8 is assigned to the filling for supplying fuel in the motor vehicle in the fully assembled state. head.

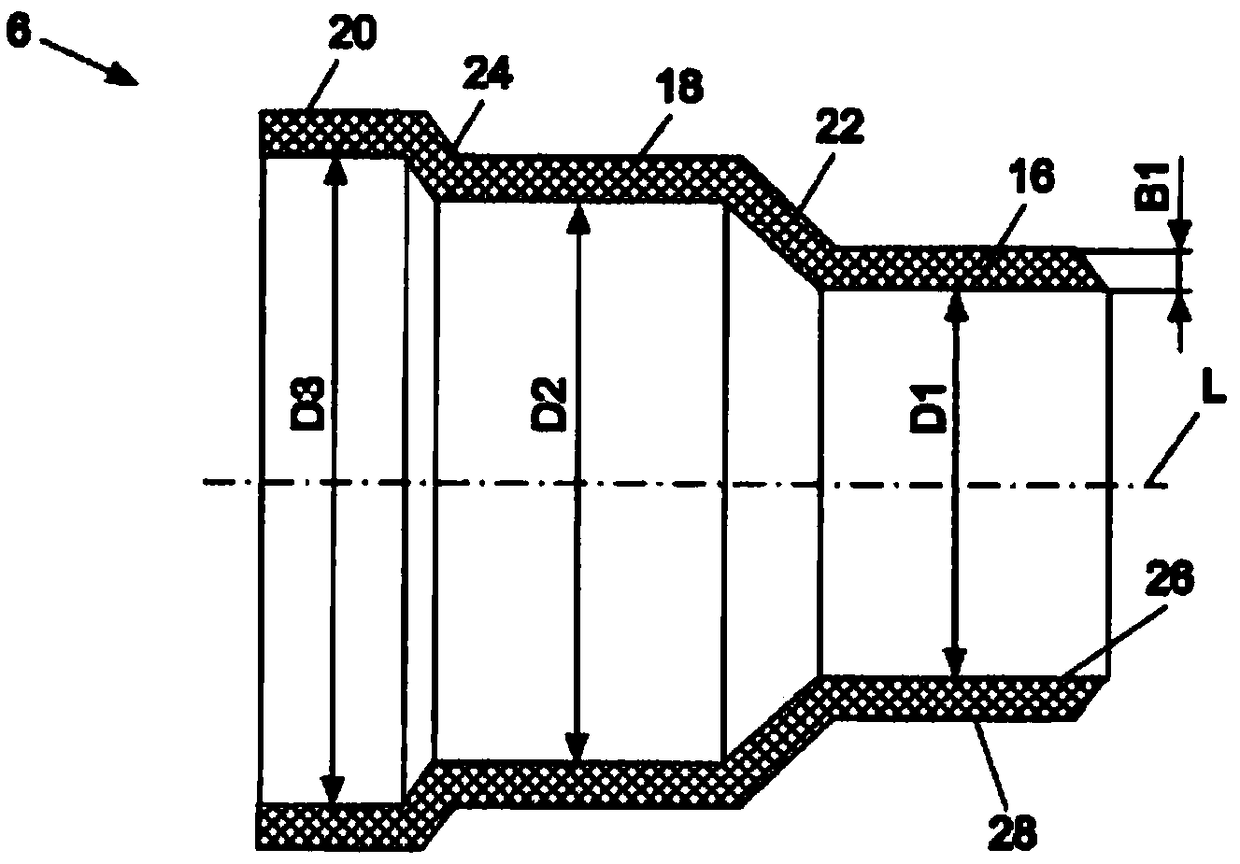

[0098] Figure 1B shown in longitudinal section Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com