Polyurethane foam sheet, method for producing same, and method for producing laminate

A manufacturing method, polyurethane technology, applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of hardening, peeling, sheet bubble damage, etc., and achieve the effect of excellent peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

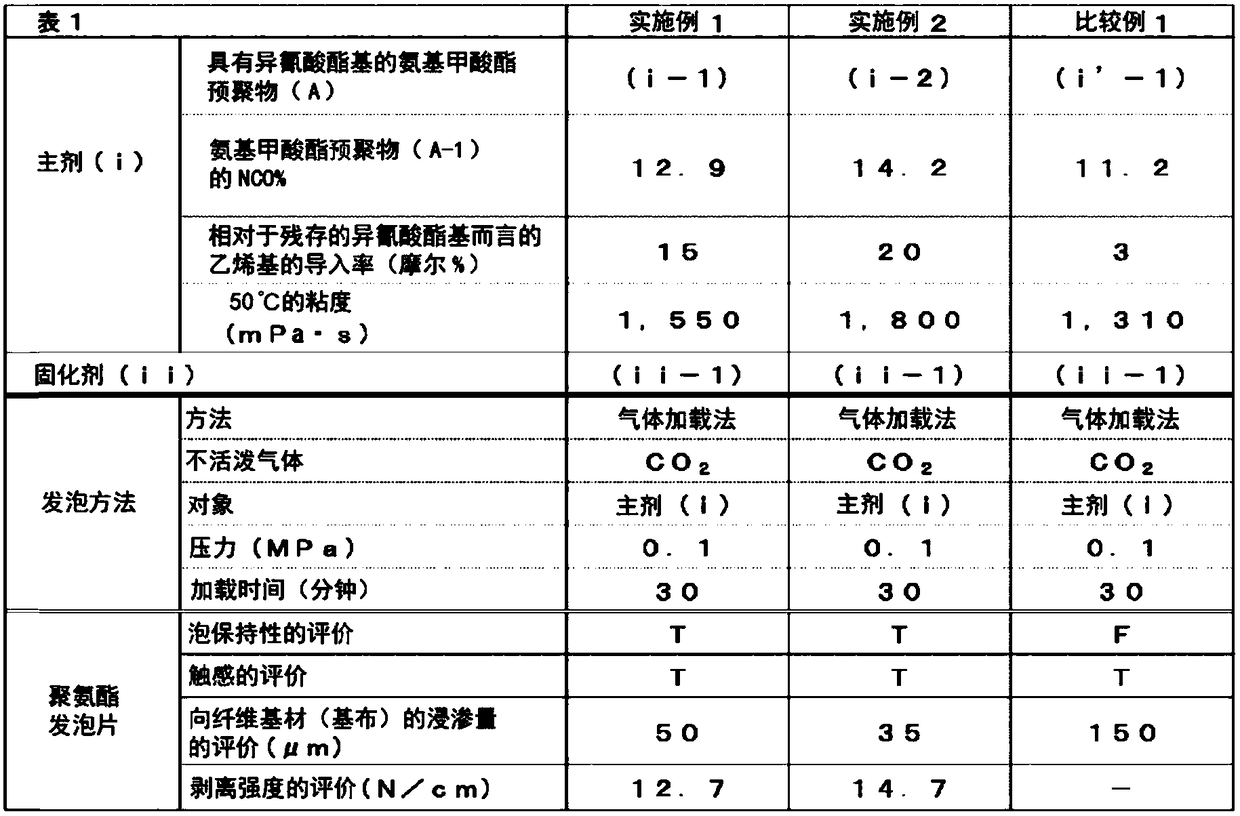

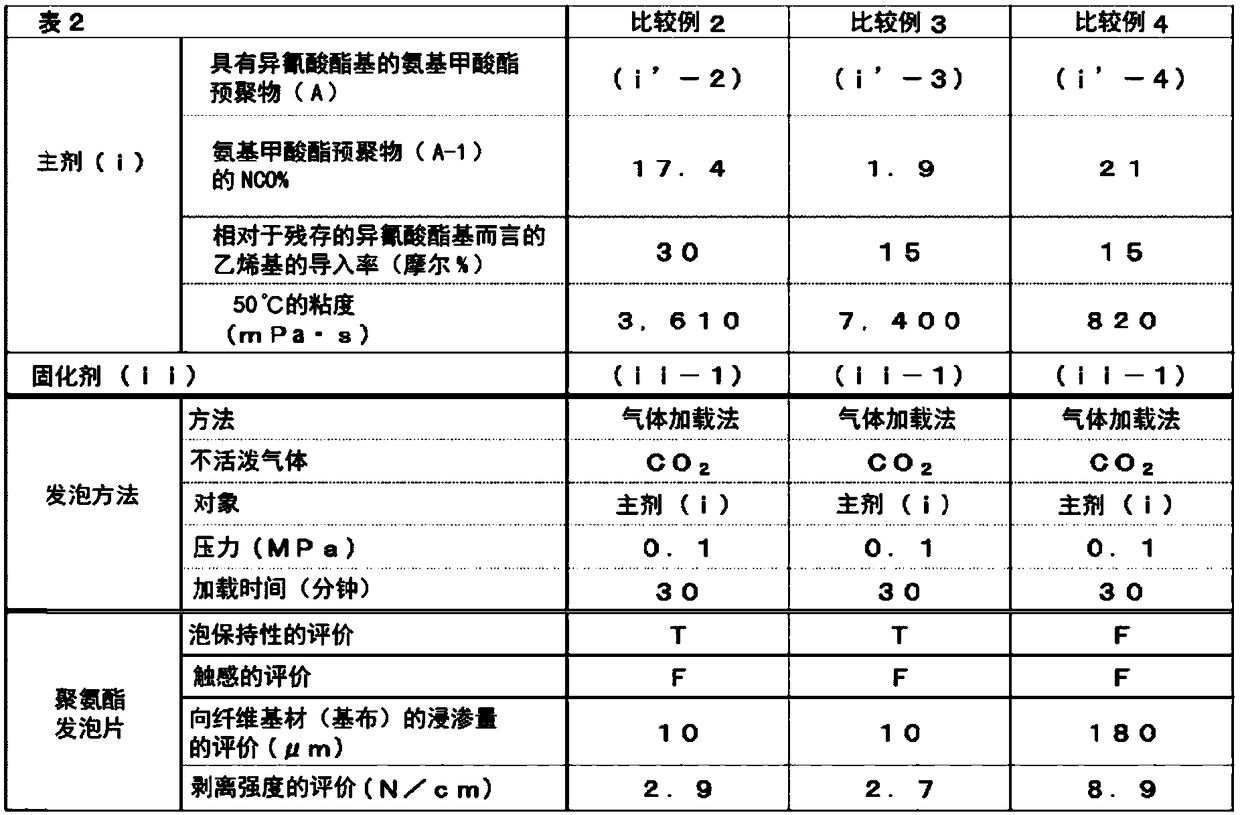

[0093] [Preparation Example 1] Preparation of main agent (i-1)

[0094] 100 parts by mass of 4,4'-diphenylmethane diisocyanate (hereinafter abbreviated as "MDI"), 120 parts by mass of polytetramethylene glycol ("PTMG2000" manufactured by Mitsubishi Chemical Corporation, number average molecular weight: 2,000) into a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux condenser, and reacted at 80° C. for 3 hours to obtain NCO%: 12.9% by mass of the urethane prepolymer (A -1-1).

[0095] Next, 11.8 parts by mass of 2-hydroxyethyl acrylate (hereinafter, abbreviated as "HEA") was added and reacted at 60°C for 2 hours to obtain an acryloyl group introduced into 15 mol% of the remaining isocyanate groups. The obtained urethane prepolymer (Ai) was used as the main ingredient (i-1). The viscosity of the main ingredient (i-1) at 50°C was 1,550 mPa·s.

preparation example 2

[0096] [Preparation example 2] preparation of main agent (i-2)

[0097] Add 100 parts by mass of MDI and 107 parts by mass of PTMG2000 into a four-necked flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux condenser, and react at 80°C for 3 hours to obtain NCO%: 14.2% by mass of amino Formate prepolymer (A-1-2).

[0098] Next, 16 parts by mass of HEA was added and reacted at 60° C. for 2 hours to obtain a urethane prepolymer (Aii) in which 20 mol % of the remaining isocyanate groups were introduced with acryloyl groups, which was obtained as Main ingredient (i-2). The viscosity of the main ingredient (i-2) at 50°C was 1,800 mPa·S.

preparation example 3

[0099] [Preparation Example 3] Preparation of main agent (i'-1)

[0100] Add 100 parts by mass of MDI and 150 parts by mass of PTMG2000 into a four-neck flask equipped with a thermometer, a stirrer, an inert gas inlet, and a reflux condenser, and react at 80°C for 3 hours to obtain NCO%: 11.2% by mass of amino Formate prepolymer (A'-1-1).

[0101] Next, 2.3 parts by mass of HEA was added and reacted at 60°C for 2 hours to obtain a urethane prepolymer (A'i) in which an acryloyl group was introduced into 3 mol% of the remaining isocyanate groups, This was used as the main ingredient (i'-1). The viscosity of the above-mentioned main ingredient (i'-1) at 50°C was 1,310 mPa·S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com