Batch-type factory-like recirculating aquaculture method

A circulating aquaculture and industrialization technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of low removal efficiency of the biological filtration system, small number of microorganisms in the biological reaction tank, and small effect of the biological reaction tank, etc., to achieve The effect of reducing breeding costs, reducing energy consumption, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

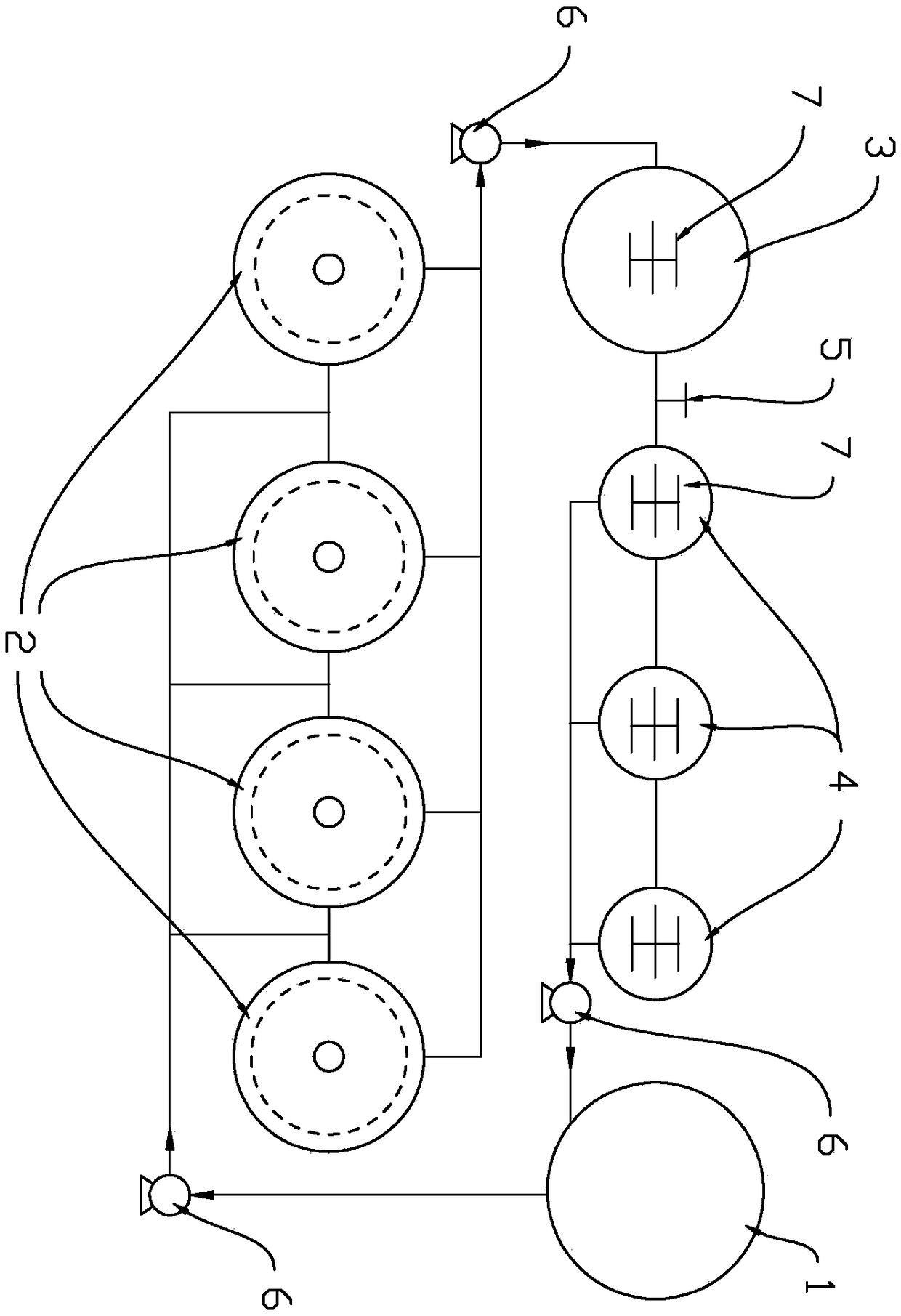

[0020] refer to figure 1 , the present invention is a kind of batch-type factory-like circulating aquaculture method, comprising a water storage tank 1, a culture tank 2, a primary reaction tank 3 and a secondary reaction tank 4 connected in series to form a loop;

[0021] Also includes the following steps:

[0022] 1) The culture pond 2 drains water to the primary reaction tank 3, and when the culture pond 2 drains water to the primary reaction pond 3, the water storage tank 1 supplies water to the culture pond 2 to maintain a constant water level in the culture pond 2;

[0023] 2) When the culture pond 2 drains into the primary reaction pool 3, the primary reaction pool 3 drains into the secondary reaction pool 4, and when the water levels in the primary reaction pool 3 and the secondary reaction pool 4 reach the set height, The culture pond 2 and the primary reaction pond 3 stop draining, and the primary reaction pond 3 and the secondary reaction pond 4 simultaneously proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com