Cyclone washing device capable removing sulphur and dust

A technology of cyclone washing, desulfurization and dust removal, which is applied in the direction of using liquid separation agent, gas treatment, membrane technology, etc., to achieve the effect of low cost, simple structure and affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

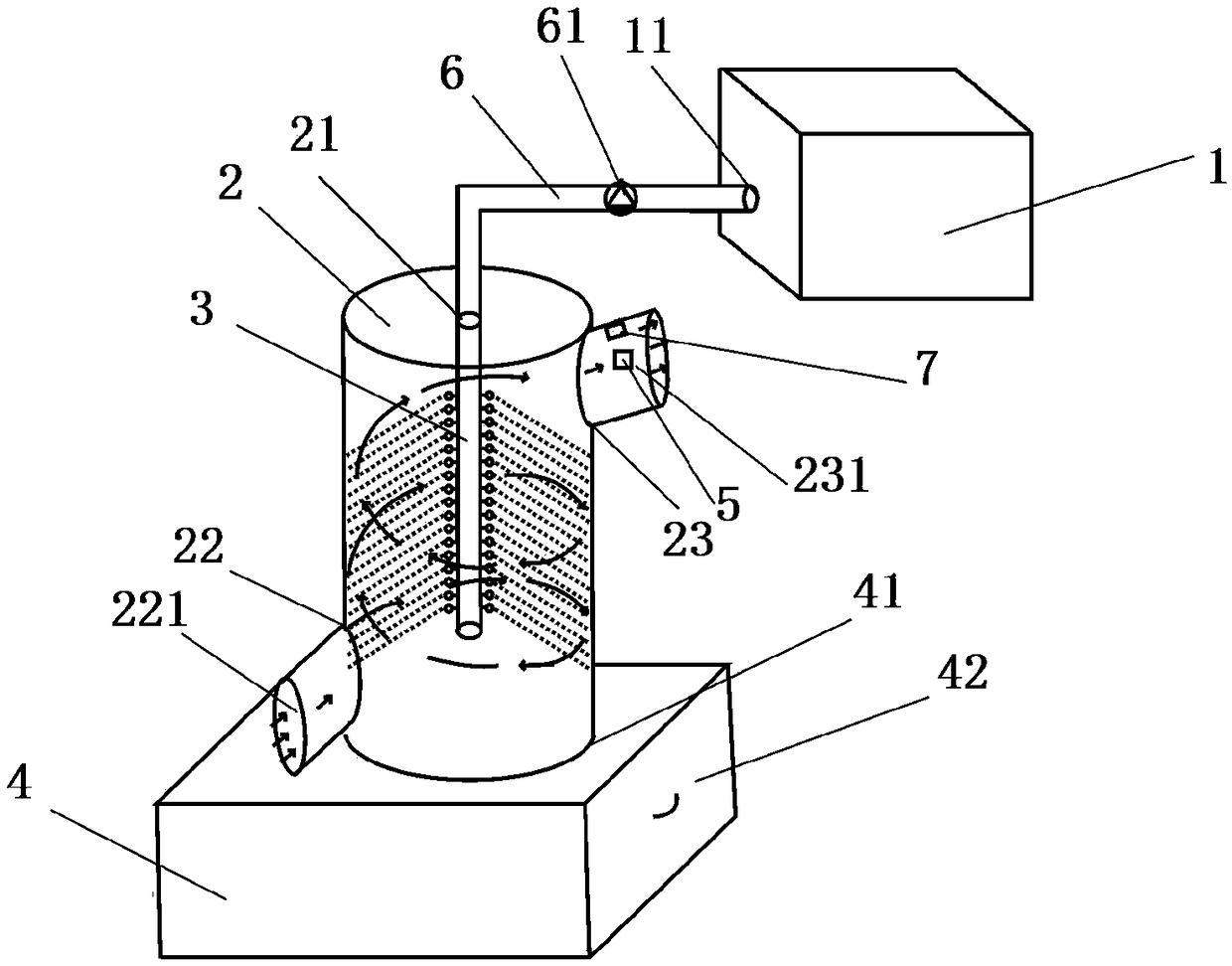

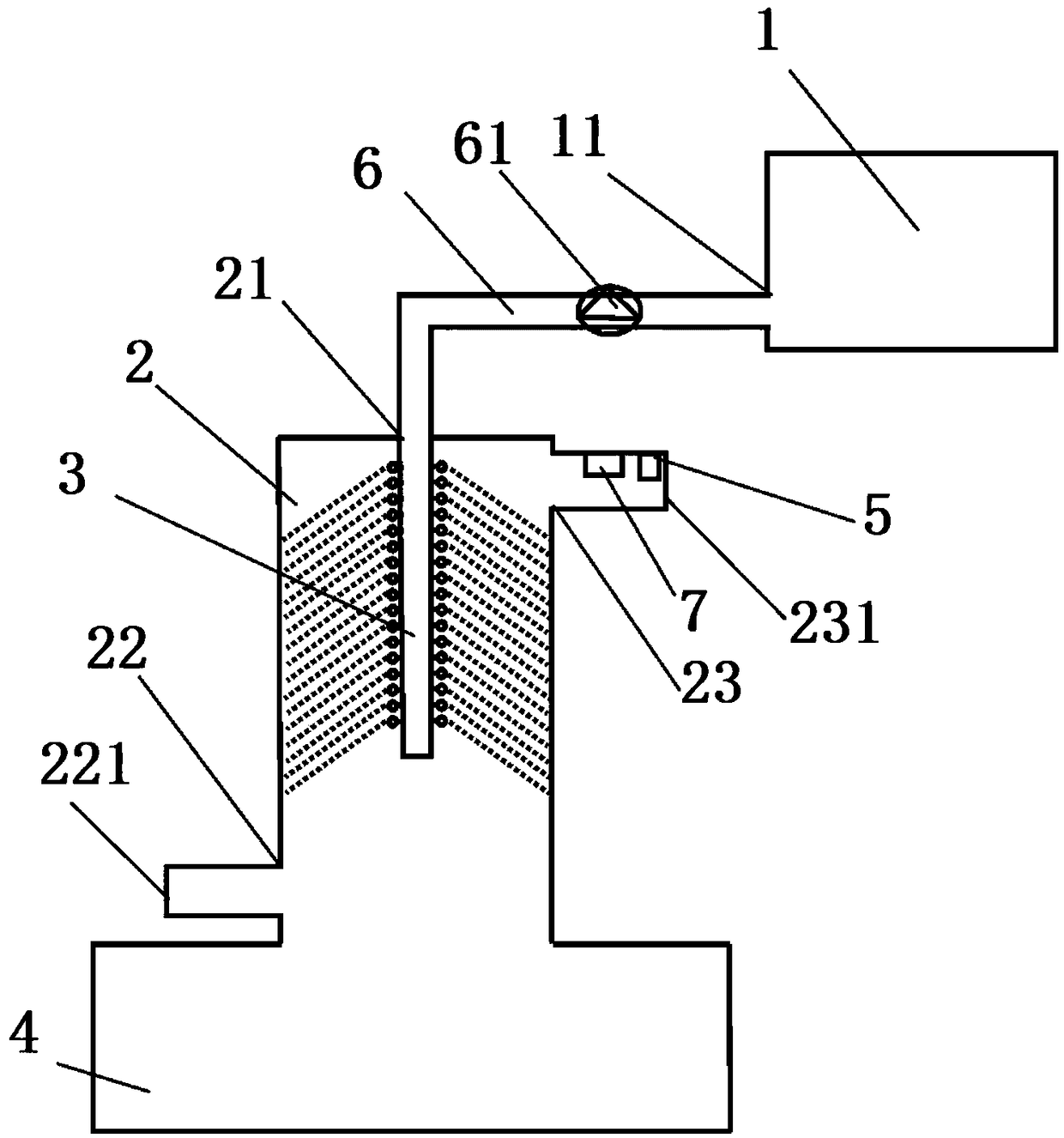

[0020] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides a cyclone washing device capable of desulfurization and dust removal, including a liquid storage tank 1, a cylinder body 2, a spray porous pipe 3, a collection box 4 and a single-chip microcomputer 5, and the liquid storage tank 1 is located above the cylinder body 2 , the collection box 4 is located below the cylinder body 2, the spray porous pipe 3 is located inside the cylinder body 2, the liquid storage tank 1 is connected to the spray porous pipe 3, the collection box 4 is connected to the cylinder body 2, and the liquid storage tank 1 is filled with lime Water, and the lime water is transported into the spray porous pipe 3, and the spray porous pipe 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com