Valve element assembling and locking equipment and using method thereof

A valve core and equipment technology, applied in metal processing equipment, using liquid/vacuum degree for liquid tightness measurement, by measuring the increase and deceleration rate of fluid, etc., can solve the one-way airtightness detection of automatic airtightness detection equipment, It cannot meet the high-precision detection requirements of faucets, does not have the air-tightness detection function, etc., so as to reduce the purchase amount of equipment, improve assembly efficiency and detection accuracy, and save manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

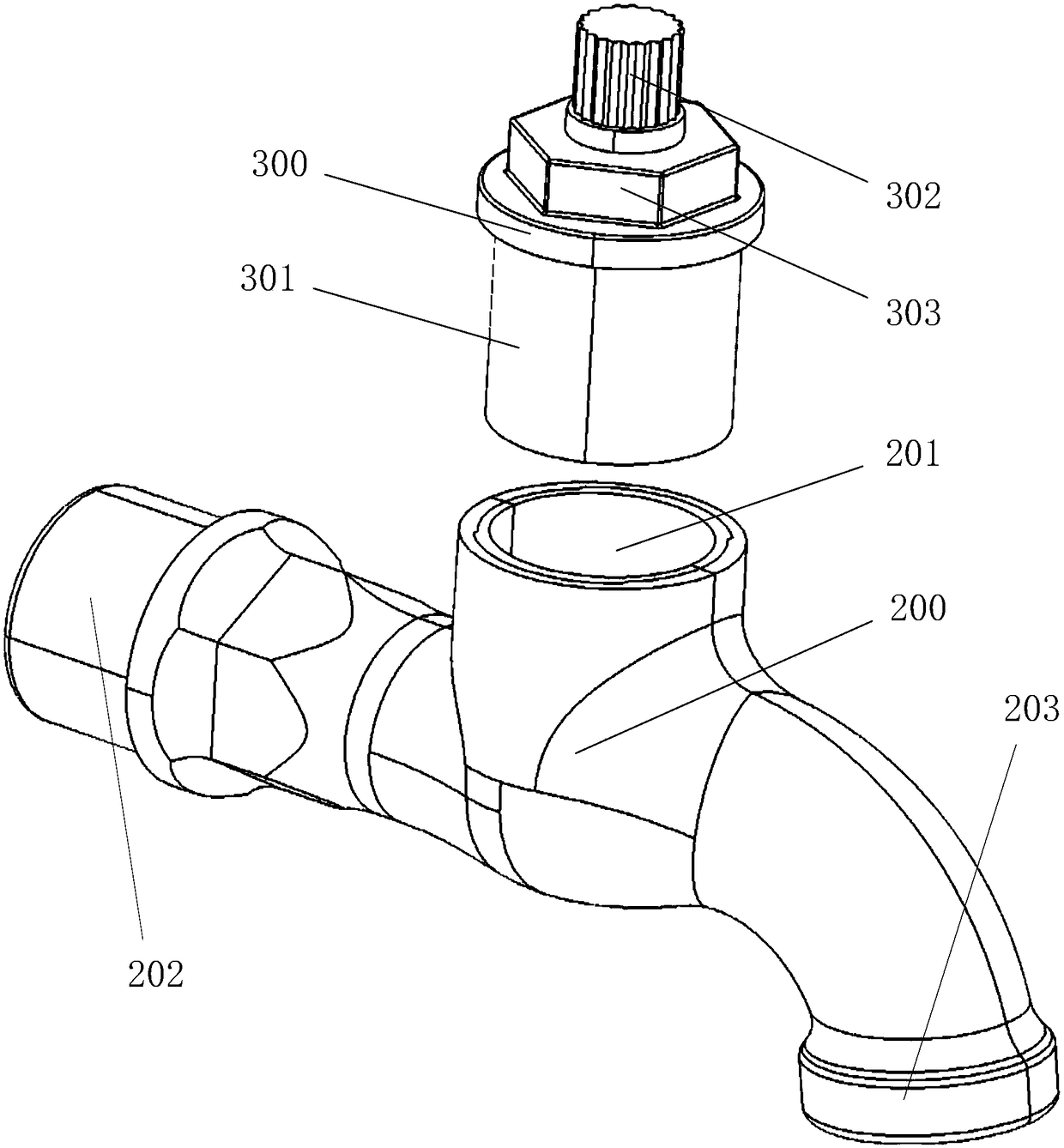

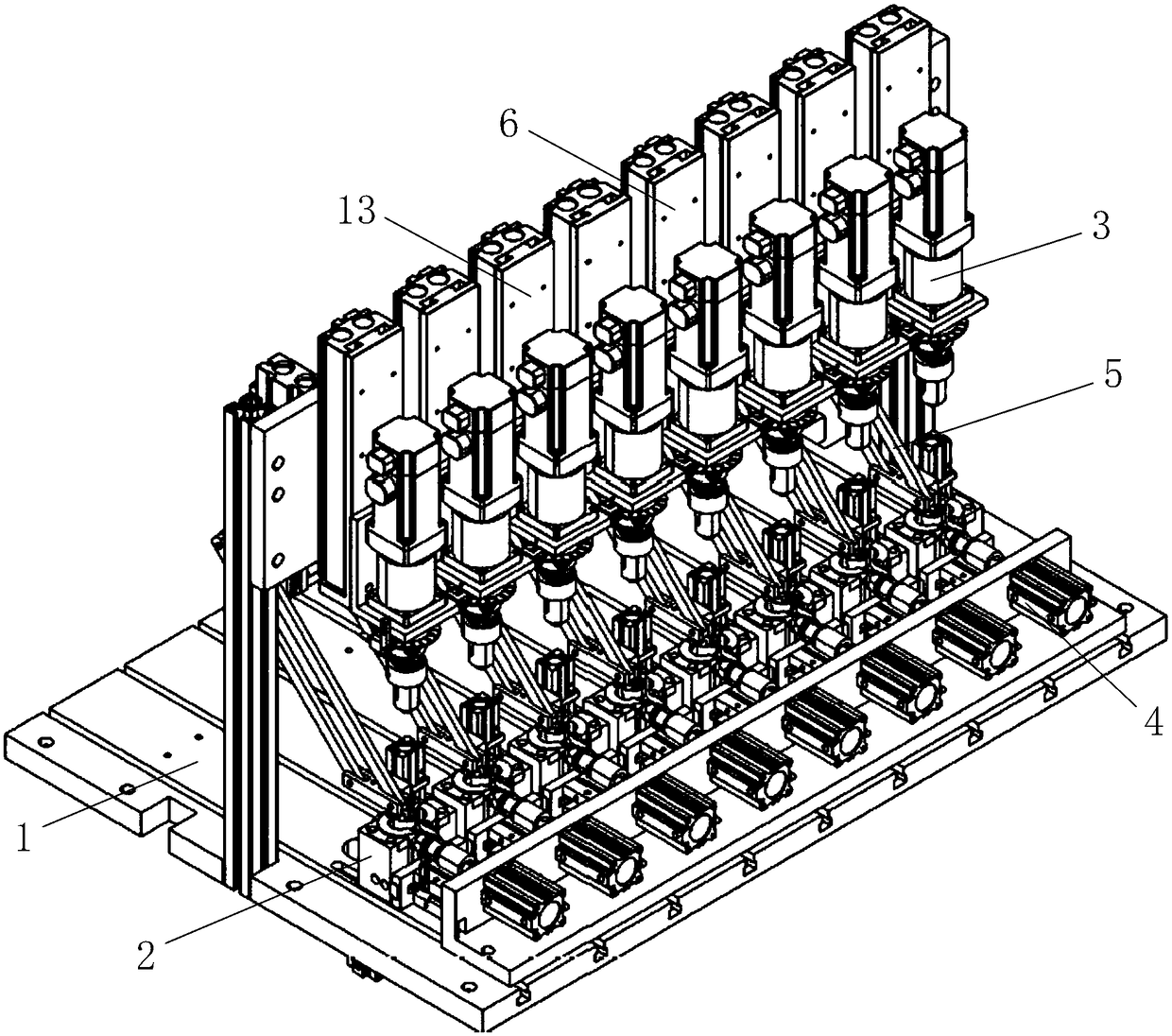

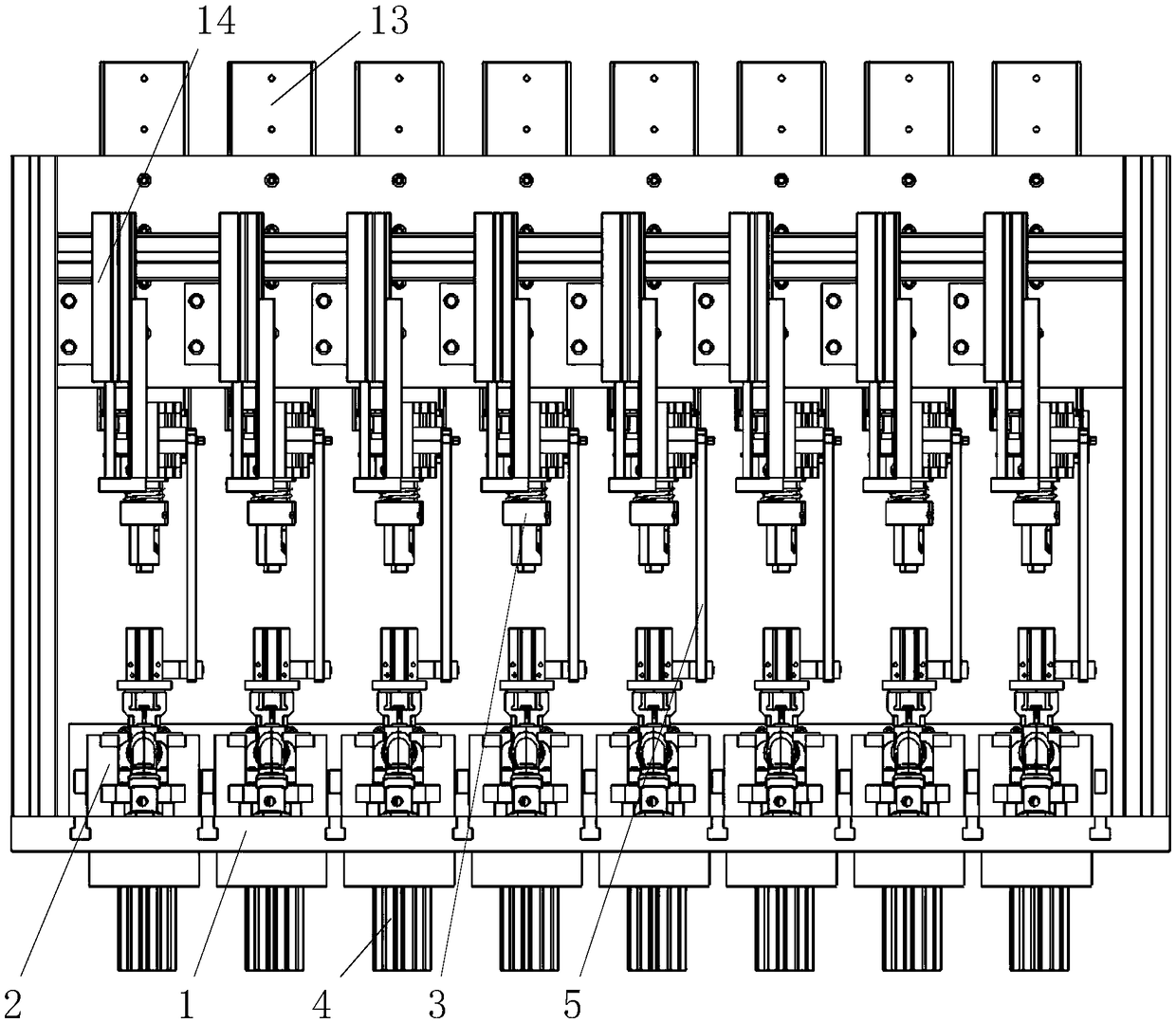

[0042] Such as figure 2 , image 3 and Figure 4 As shown, the embodiment of the present application proposes a valve core assembly and locking device, which includes a body 1 , a clamping and fixing unit 2 , a locking switch unit 3 and an airtight detection unit 4 arranged on the body 1 . Among them, the clamping and fixing unit 2 is used to accommodate and fix the valve body 200, prevent the valve body 200 from moving during the assembly process, and facilitate the locking switch unit 3 to lock the valve core 300 on the valve body 200 and facilitate airtight testing. The unit 4 is connected with the valve body 200 . The locking switch unit 3 can move relative to the clamping and fixing unit 2 to move to the valve body 200 and the valve core 300 in the clamping and fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com