Construction method of bulkhead intermediate product of biphasic stainless steel chemical ship

A duplex stainless steel and construction method technology, applied in ship construction, ship parts, ships, etc., can solve problems such as incomplete installation of outfitting parts, legacy of outfitting parts, and poor integrity of intermediate products, so as to prevent galvanic corrosion, The effect of improving construction quality and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

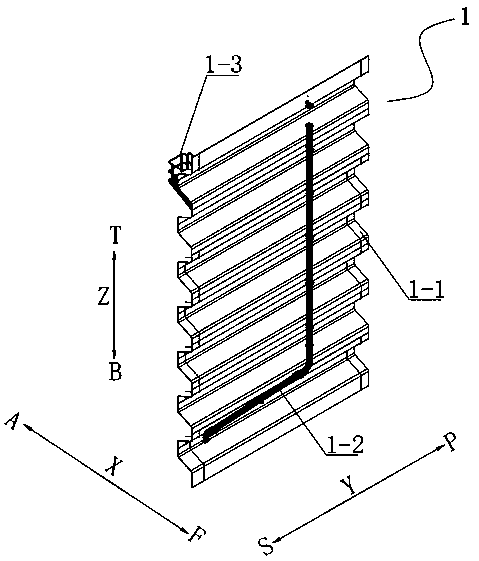

[0052] Example: such as figure 1 As shown, the intermediate product 1 of the duplex stainless steel chemical tanker compartment includes a trough compartment structure 1-1, a liquid cargo piping system 1-2, and an inclined ladder platform 1-3. In this embodiment, the ship's length direction is represented by "X", wherein the stern direction is represented by "A", the bow direction is represented by "F"; the ship's width direction is represented by "Y", wherein the port side is represented by "P" The starboard side is represented by "S"; the ship's height direction is represented by Z, among which, the bottom is represented by "B" and the top is represented by "T".

[0053] A method for constructing an intermediate product of a duplex stainless steel compartment for chemical tankers, comprising the following steps:

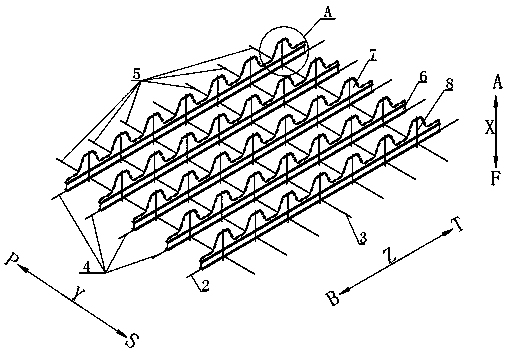

[0054] Step 1. Set up a tire frame for welding in a grooved compartment on the floor, such as figure 2 As shown, use the laser theodolite to draw the reference ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com