Rare earth superstrong steel and preparation method thereof

A rare earth and super-strength technology, applied in the field of metallurgy, can solve the problems of high cost of maraging steel, inability to maintain good plasticity at the same time, and restrictions on widespread use, so as to overcome low plasticity, high tensile strength, and reduce use volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a preparation method for the rare earth super-strength steel described in the above technical solution, comprising the following steps:

[0039] (1) heat-preserve and forge the billet corresponding to the rare earth super-strength steel component at 1200±15° C., and obtain the billet after air cooling;

[0040] (2) heating the forging billet in the step (1) to 905±15° C. for heat preservation to obtain a billet;

[0041] (3) Perform aging treatment on the billet obtained in the step (2) at 500±50° C. to obtain rare earth super-strength steel.

[0042] In the present invention, the casting slab corresponding to the rare earth super-strength steel component is successively heat-insulated and forged at 1200±15° C., and the forged slab is obtained after air cooling. In the present invention, the cast slab made of the raw materials is preferably prepared by melting first and then pouring. The present invention has no special restrictions on th...

Embodiment 1

[0048] Two-component test steel slabs (see Table 1 for specific alloy composition) were produced by the conventional method of first smelting and then casting, and the slab (the size of the slab was 300×250×50mm) was heated to 1200°C±15°C , after 30 minutes of heat preservation, forging to a thickness of 30mm, and then air cooling to room temperature to obtain a forging billet;

[0049] Heating the forging billet to 900°C, keeping it warm for 2 hours, and then cooling it with water to obtain a billet;

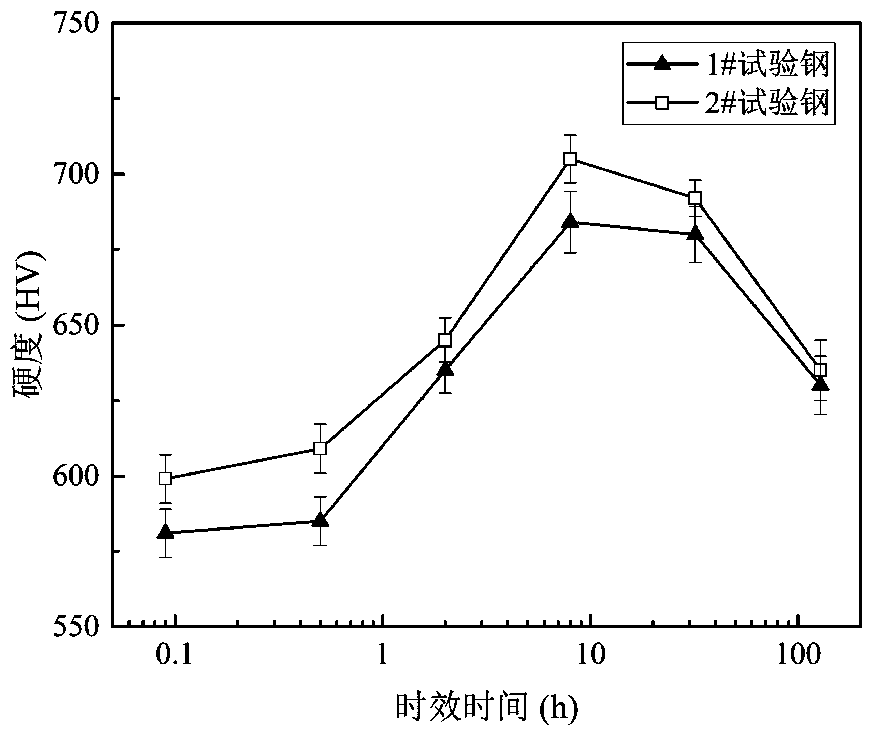

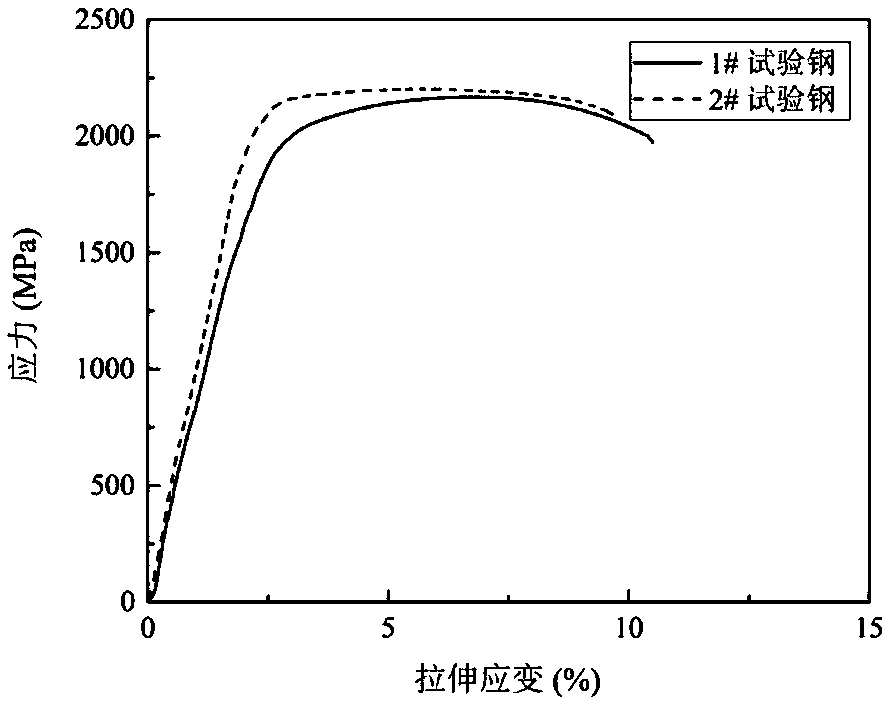

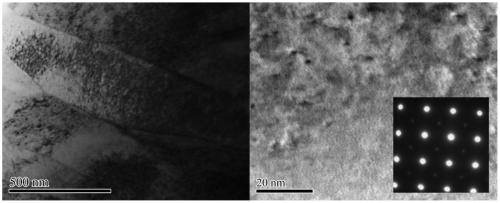

[0050] Cut out a sample with a size of 20×20×130 mm from the billet, heat the sample to 500° C. and then perform aging heat treatment, and air cool to room temperature after the aging heat treatment.

[0051] Alloy composition of table 1 test steel (wt.%)

[0052] serial number

Ni

Al

Mo

Nb

C

B

mn

W

La

Ce

Fe

1# test steel

15.332

2.619

0.059

0.763

0.026

0.017

3.394

0.182

0.008

0

margin

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com