Car mold PVD stripping solution and preparing method thereof

A technology for automotive molds and stripping solutions, which is applied in the field of stripping solutions for automotive mold PVD and its preparation, can solve problems such as mold deformation, difficulty in importing and purchasing, and low efficiency of stripping solutions, and achieve high efficiency and stripping The effect of short plating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

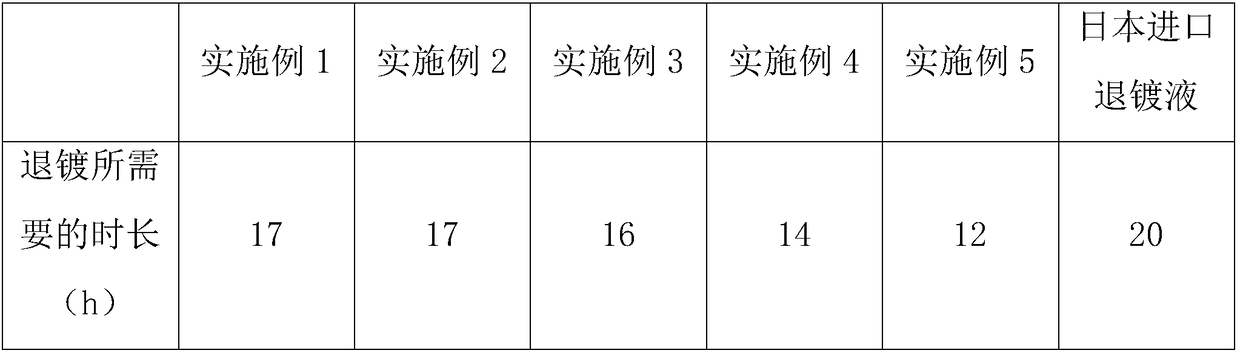

Examples

Embodiment 1

[0026] The stripping solution for PVD of automobile mold of the present embodiment is made up of following components by weight percentage: 10% sodium permanganate, 10% potassium hydroxide and 60% deionized water.

[0027] The preparation method of the deplating solution that automobile mold PVD of the present invention uses is:

[0028] (a) Weigh 10 parts of potassium permanganate, 10 parts of potassium hydroxide and 60 parts of deionized water by said weight component;

[0029] (b) drop into the deionized water of weight component described in step (a) in container;

[0030] (c) drop into the deionized water of step (b) the potassium hydroxide of weight component described in step (a), form lye, place at room temperature, drop to below 40 degrees Celsius;

[0031] (d) drop into the sodium permanganate of the weight component described in the step (a) into the lye in the lye described in the step (c), stir for 40 minutes and repack to obtain the deplating solution.

Embodiment 2

[0033] The stripping solution for the automotive mold PVD of the present embodiment is made up of the following components by weight percentage: 15% sodium permanganate, 15% potassium hydroxide and 70% deionized water.

[0034] The preparation method of the deplating solution that automobile mold PVD of the present invention uses is:

[0035] (a) Weigh 15 parts of potassium permanganate, 15 parts of potassium hydroxide and 70 parts of deionized water by said weight component;

[0036] (b) drop into the deionized water of weight component described in step (a) in container;

[0037] (c) drop into the deionized water of step (b) the potassium hydroxide of weight component described in step (a), form lye, place at room temperature, drop to below 40 degrees Celsius;

[0038] (d) drop into the sodium permanganate of the weight component described in the step (a) into the lye in the lye described in the step (c), stir for 40 minutes and repack to obtain the deplating solution.

Embodiment 3

[0040] The stripping solution for the automotive mold PVD of the present embodiment is made up of the following components by weight percentage: 20% sodium permanganate, 20% potassium hydroxide and 60% deionized water.

[0041] The preparation method of the deplating solution that automobile mold PVD of the present invention uses is:

[0042] (a) Weigh 20 parts of potassium permanganate, 20 parts of potassium hydroxide and 60 parts of deionized water by said weight component;

[0043] (b) drop into the deionized water of weight component described in step (a) in container;

[0044] (c) drop into the deionized water of step (b) the potassium hydroxide of weight component described in step (a), form lye, place at room temperature, drop to below 40 degrees Celsius;

[0045] (d) drop into the sodium permanganate of the weight component described in the step (a) into the lye in the lye described in the step (c), stir for 40 minutes and repack to obtain the deplating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com