Manufacturing method of anti-blue light glasses capable of automatically dimming

A technology of automatic light adjustment and production method, which is applied in the directions of glasses/goggles, optics, optical components, etc., which can solve the problems of serious eye damage and achieve good anti-blue light effect and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

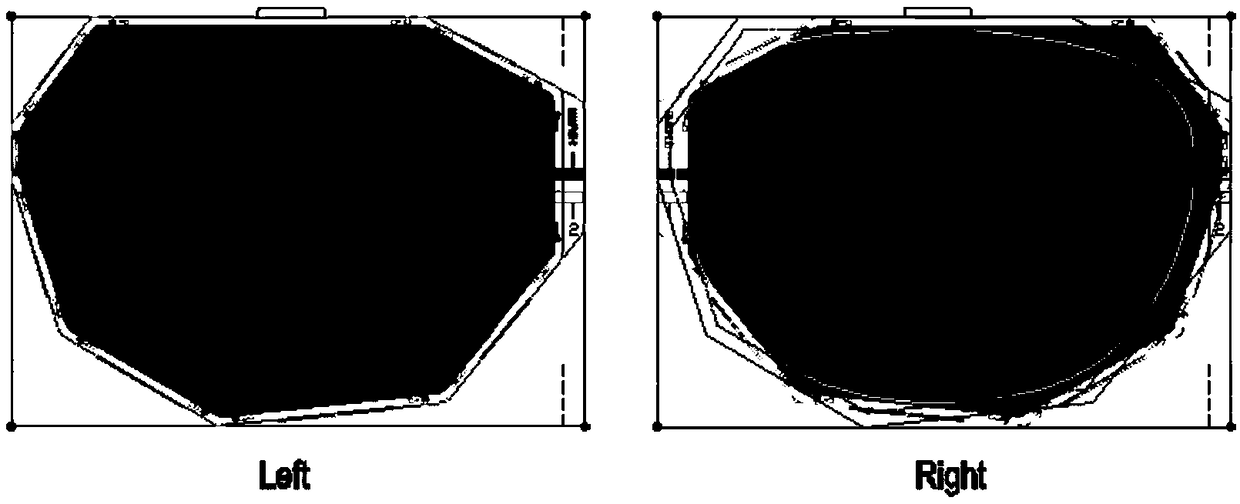

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0030] A method for making anti-blue light automatic dimming glasses, which comprises the following process steps:

[0031] S1. Production raw materials: The raw materials include two pieces of glass, one of which is coated with anti-blue light film and the other side is coated with ITO film, and the other glass is coated with ITO film on one side, and the other side is left untreated. After post-processing, the two pieces of glass are The ITO-coated side is tightly pressed together to form a piece of blue light automatic dimming spectacle lens; at 800 nanometers (nm), the transmittance of blue light is 60%. ITO glass coated with anti-blue light film uses existing film-making equipment to manufacture anti-blue light film, and the blue light film is placed in place. Means such as post-processing and pressing are all existing technical means in the field, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com