A laser aluminum alloy cooling box that is easy to install and disassemble

A technology of aluminum alloy and heat dissipation box, which is applied in the field of lasers, can solve the problems of inconvenient laser fixing, inconvenient disassembly and installation, and single heat dissipation method, so as to achieve the effects of convenient protection, improved efficiency, and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

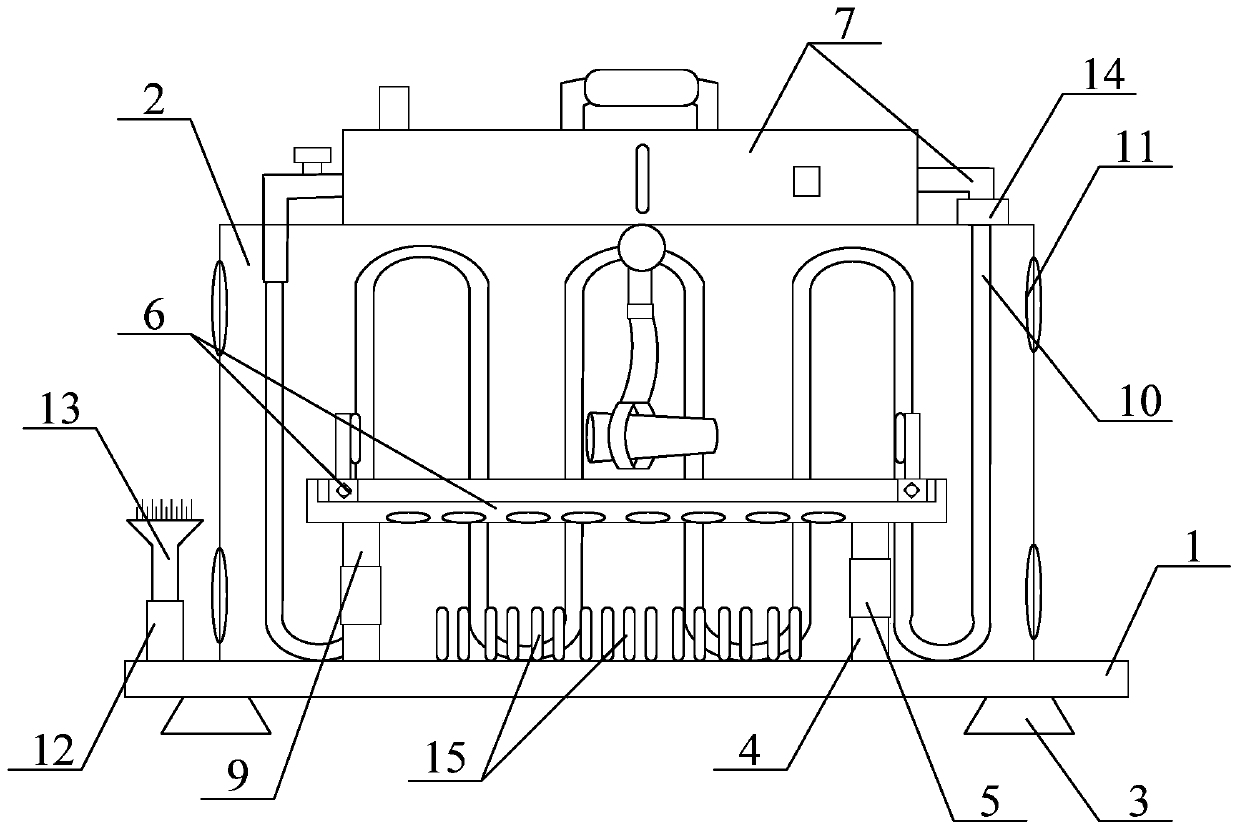

[0035] The present invention will be further described below in conjunction with accompanying drawing:

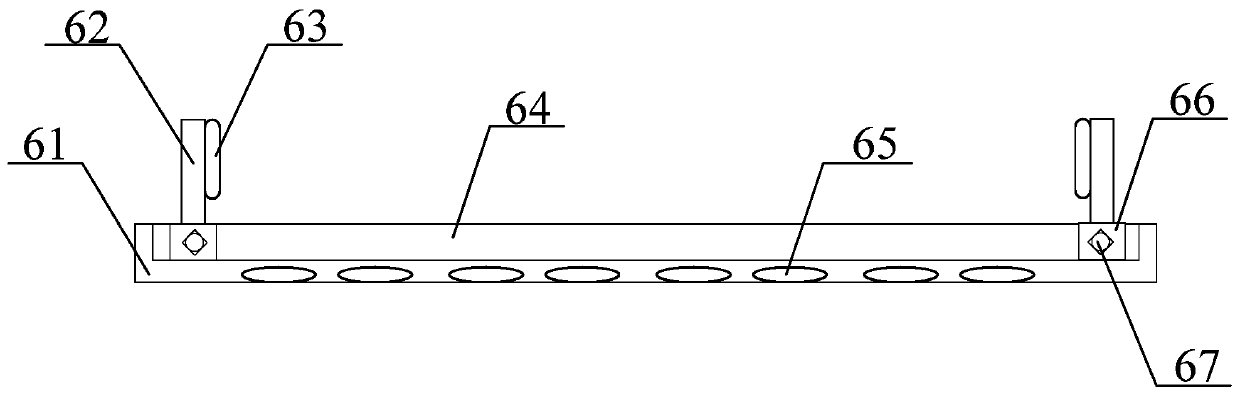

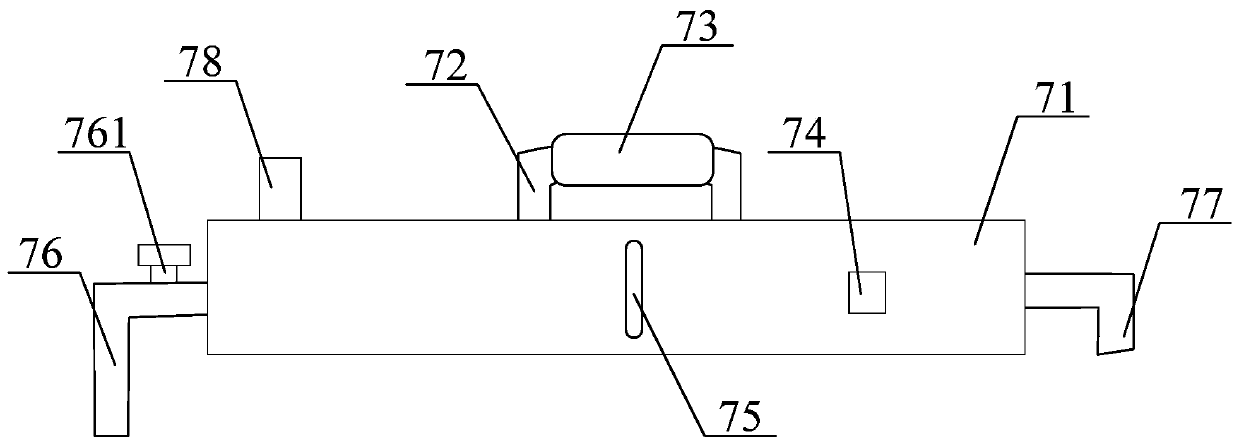

[0036] Such as figure 1 , figure 2 As shown, a kind of laser aluminum alloy cooling box that is easy to install and disassemble according to the present invention includes a fixed installation base plate 1, an aluminum alloy cooling box body 2, a fixed suction cup 3, a first wire lever 4, and a long nut 5, which can be adjusted Laser placement plate structure 6, easy to replace cooling water Cooling water tank structure 7, rotatable dust-proof laser protective cover structure 8, second wire lever 9, serpentine heat dissipation pipe 10, heat dissipation vent 11, inserting socket 12, cleaning brush 13 , cooling circulation pump 14 and cooling fins 15, the aluminum alloy cooling box body 2 is bolted to the middle position of the upper surface of the fixed installation base plate 1; ; The first wire lever 4 is respectively welded at the four corners of the inner lower surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com