Overwater floating heat-pipe-radiating thermoelectric power generating set

A technology of floating on water surface and thermoelectric power generation, applied in the direction of generators/motors, electrical components, etc., can solve problems such as restricting the application of thermoelectric power generation technology, affecting the efficiency of thermoelectric power generation devices, thermal expansion and contraction of thermoelectric power generation sheets, etc., to achieve excellent condensation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

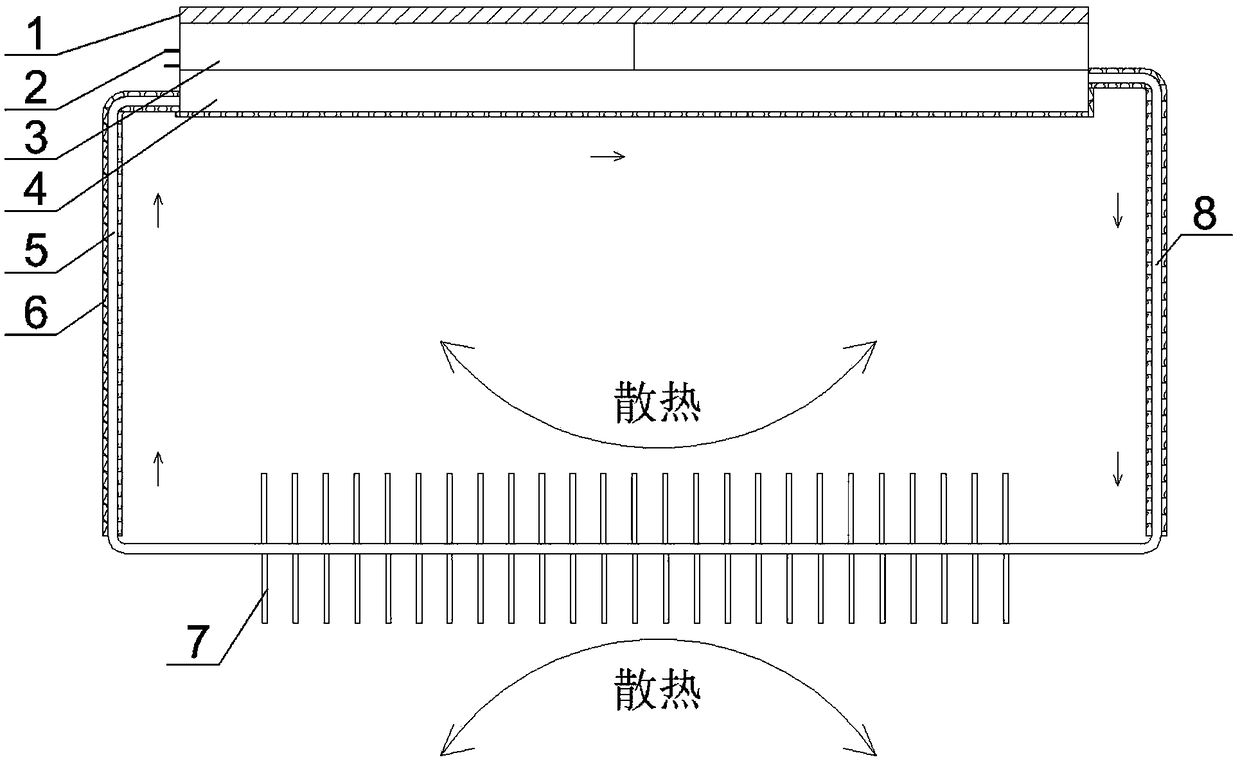

[0022] The embodiment of the present invention includes a solar heat absorbing plate 1, a thermoelectric power generation sheet group 3 and a loop heat pipe cooling system;

[0023] The solar heat absorbing plate 1 is arranged on the heat absorbing end of the thermoelectric power generation sheet group 3 through heat conducting glue, the solar heat absorbing plate 1 is made of copper or aluminum thin plate, and the upper surface of the solar heat absorbing plate 1 is coated with a photovoltaic plate to absorb heat Paint film.

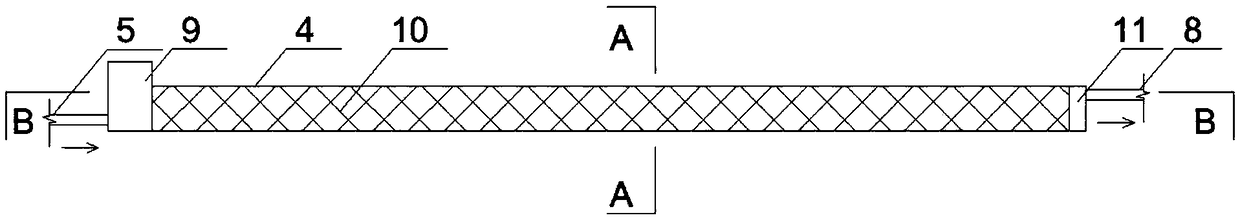

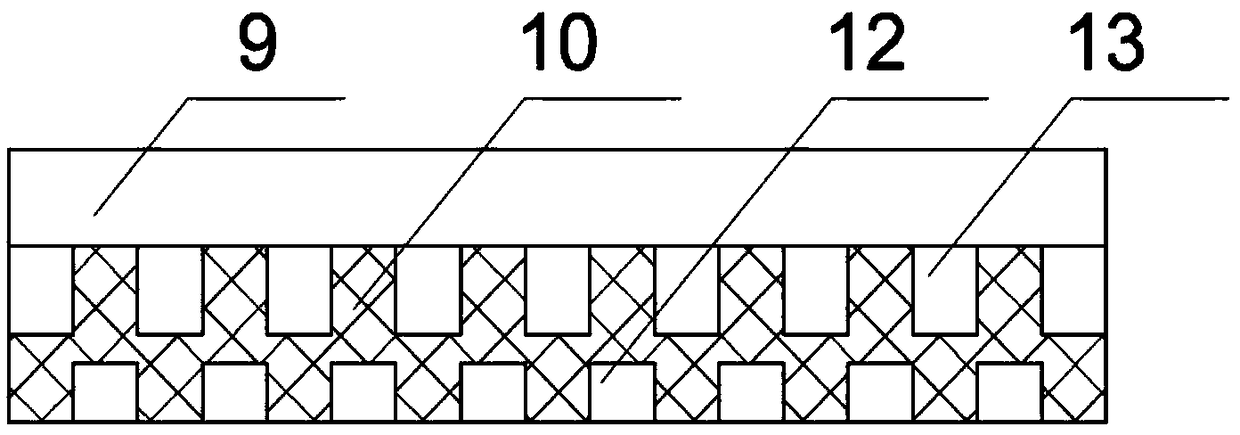

[0024] The loop heat pipe cooling system includes an evaporator 4 and a condenser 7 , and the lower surface of the evaporator 4 is pasted with a rubber-plastic closed-cell insulation layer 6 .

[0025] The liquid inlet of the evaporator 4 is communicated with the liquid outlet of the condenser 7 through a liquid pipeline 5, and the outer wall of the liquid pipeline 5 is provided with an insulating buoyancy layer of rubber and plastic closed-cell materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com