Stone-plastic composite board and production method thereof

A production method and composite board technology, which are applied in furniture parts, kitchen cabinets, household appliances, etc., can solve the problems of dust pollution, human injury, secondary pollution of the environment, etc., and achieve the effect of reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

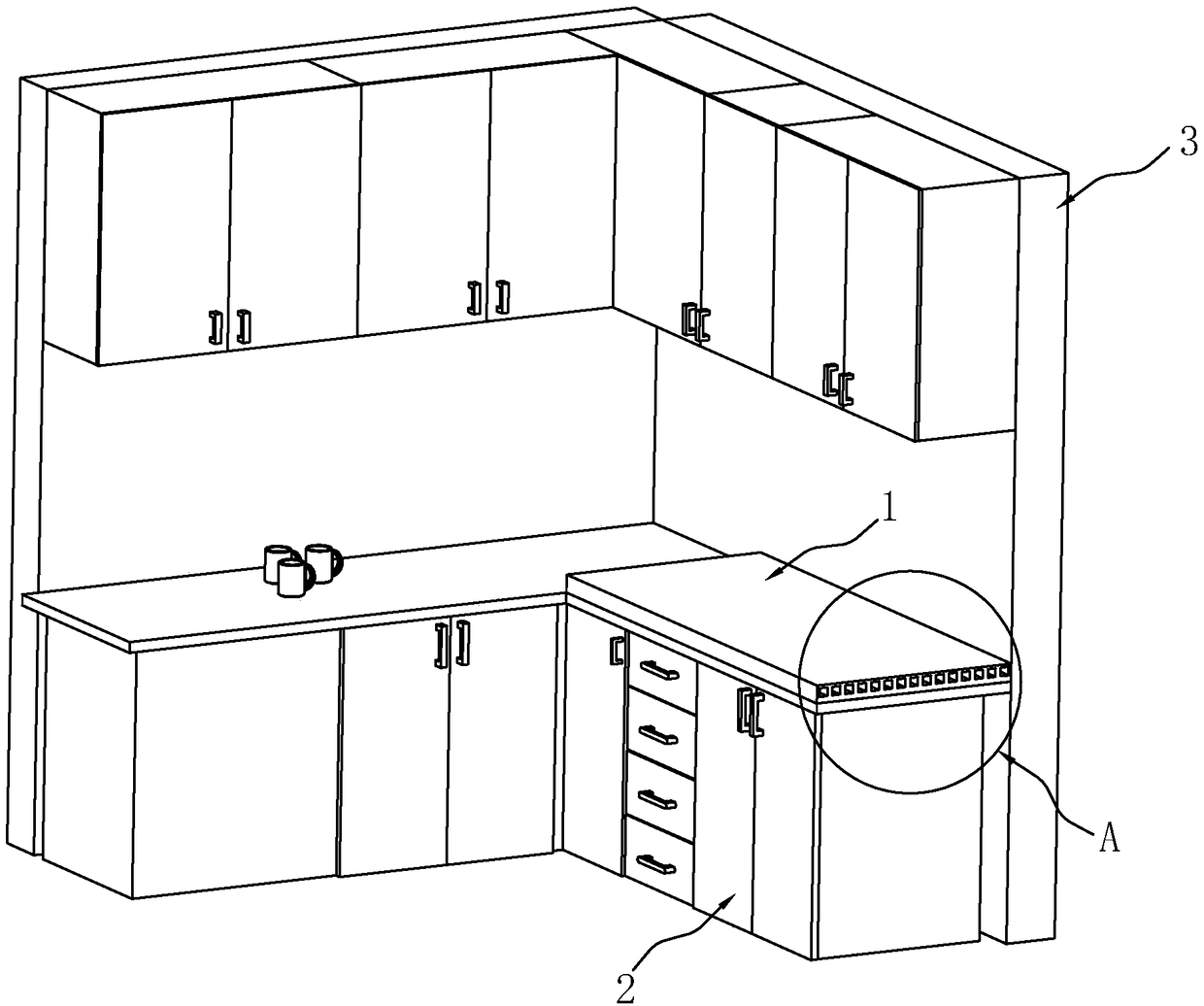

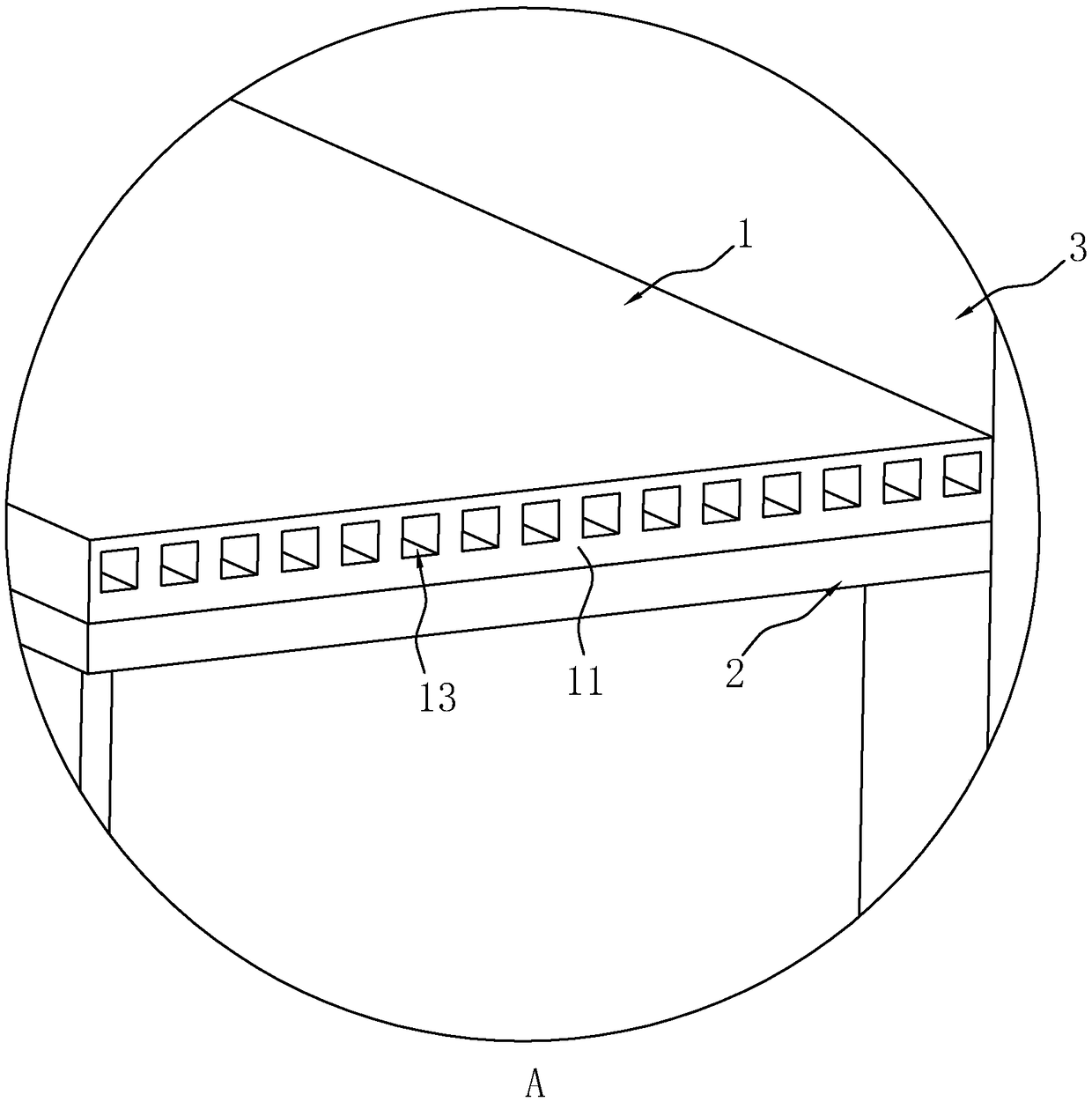

[0042] A stone-plastic composite board, such as figure 1 As shown, the stone-plastic composite board 1 is arranged on a cabinet 2, the cabinet 2 is vertically arranged on the ground, and two mutually perpendicular sides of the cabinet 2 are closely attached to the wall 3.

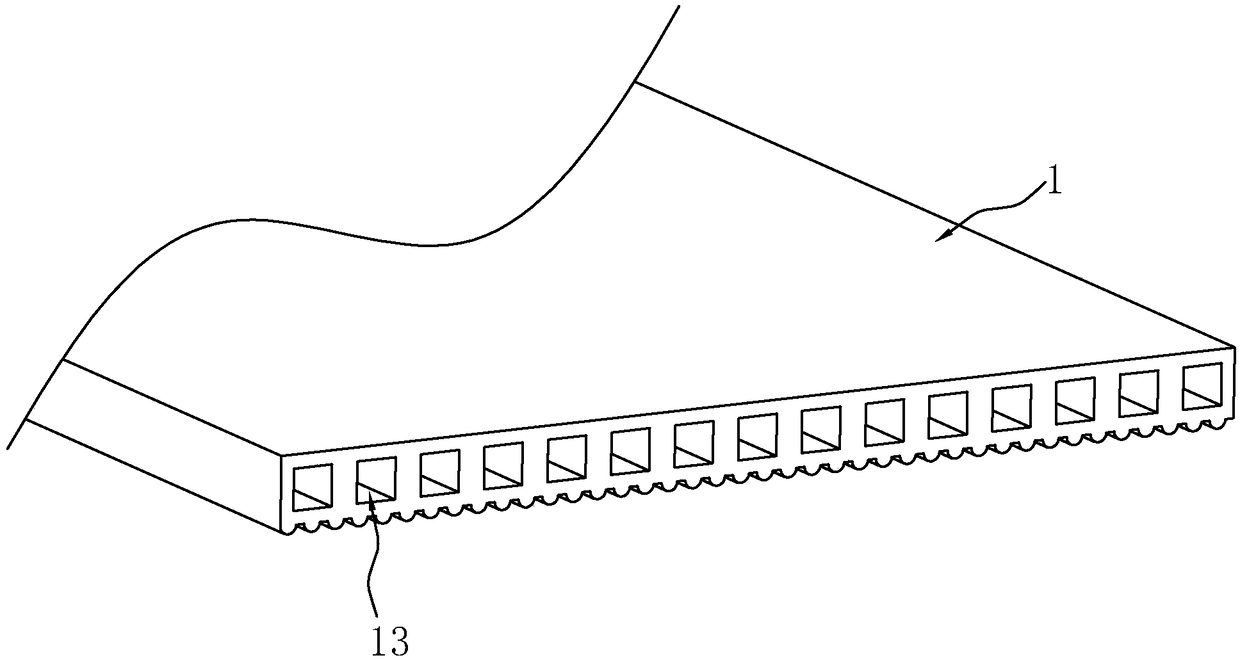

[0043] Such as figure 2 As shown, the stone-plastic composite board 1 includes a stone-plastic base layer 11 and a plastic film protective layer covering the outer side of the stone-plastic base layer 11, and the stone-plastic base layer 11 and the plastic film protective layer are wrapped into a whole body. The plastic film protective layer can be a PVC film protective layer or a PE film protective layer. The stone-plastic base layer 11 is a stone-plastic base layer 11 made by mixing PVC and stone powder. The stone-plastic base layer 11 can also be a stone-plastic base layer 11 made by mixing PVC and wood powder. In contrast, PVC and stone powder are mixed The prepared stone-plastic base layer 11 has higher ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com