A cooling control device and control method for a single-point unbalanced casting special-shaped billet crystallizer

A crystallizer and unbalanced technology, which is applied in the field of continuous casting, can solve the problems of uneven cooling of the mold and uneven cooling of the mold for single-point unbalanced casting of shaped billets, so as to avoid production accidents and facilitate asymmetric and balanced heat transfer , to ensure the effect of relative accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

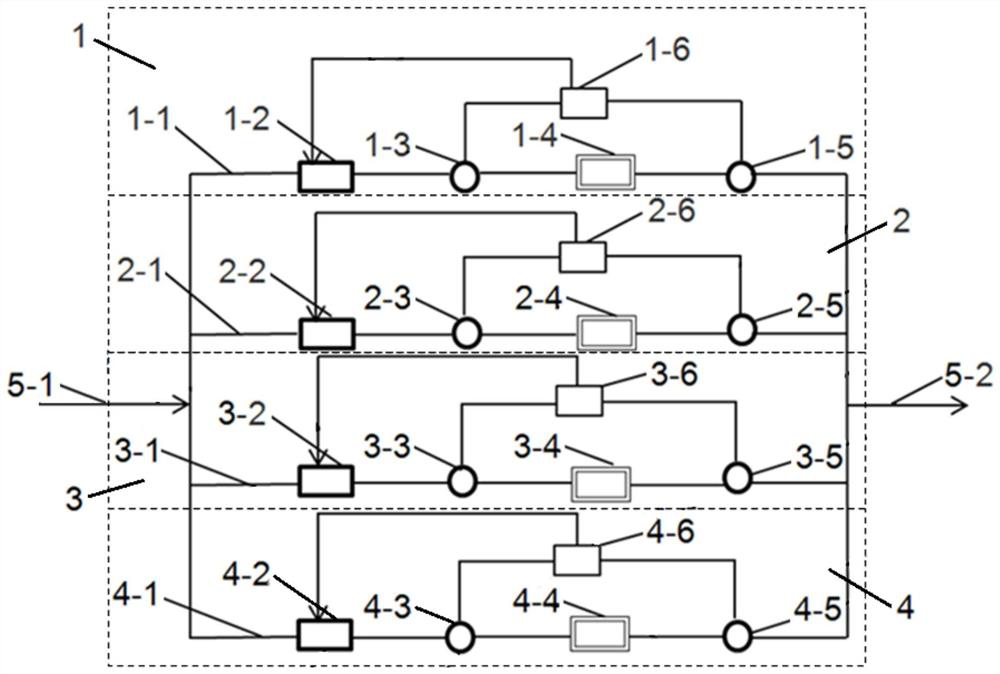

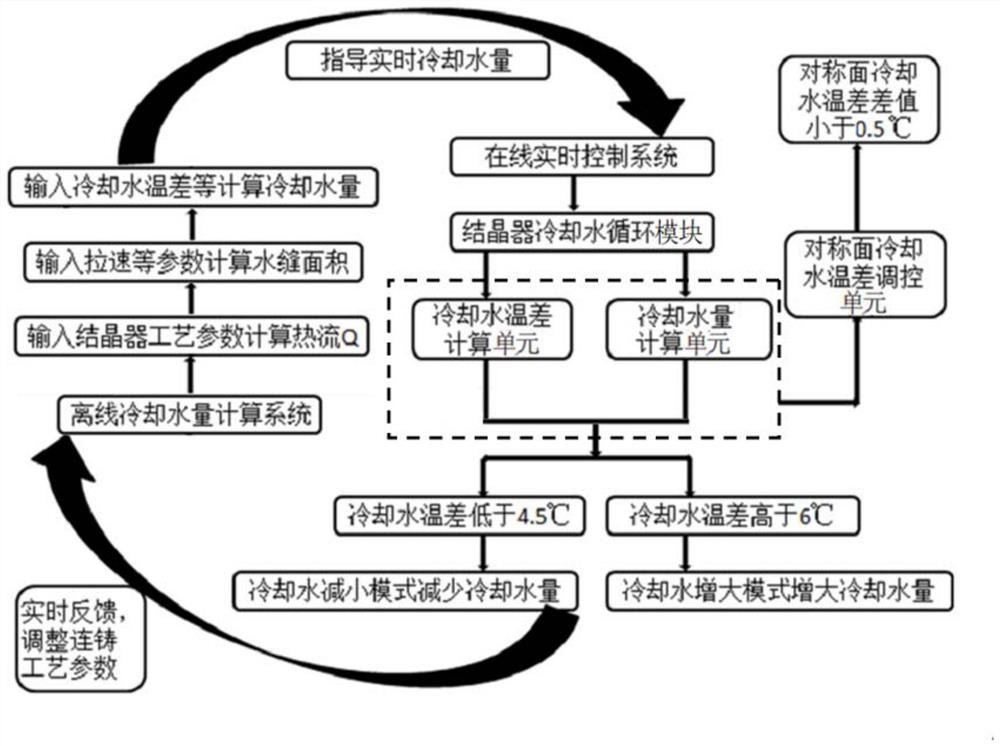

[0070] Such as figure 1 and image 3 As shown, a cooling control device for a single-point unbalanced casting shaped billet crystallizer of the present invention includes an off-line cooling water calculation system, an online real-time control system, a main water inlet pipe 5-1 and a water main pipe 5-2.

[0071] The off-line cooling water volume calculation system is used to calculate the initial cooling water volume in the offline state, guide the real-time cooling water volume, and the online real-time control system provides real-time feedback to the off-line cooling water volume calculation system, adjusts relevant continuous casting process parameters, and ensures the off-line calculation of cooling water volume relative accuracy.

[0072] The online real-time control system includes the crystallizer cooling water circulation module and the cooling water temperature difference calculation and water volume calculation unit. The online real-time control system is electr...

Embodiment 2

[0097] The control device and control method of this embodiment are the same as those of Embodiment 1, the difference is that the present invention is further explained and supported.

[0098] Such as Figure 4 and Figure 5 Shown is the flow field of molten steel during casting in the mold of single-point unbalanced casting by water simulation, and the flow field of molten steel after diffusion after a short period of time. The water simulation results show that in the single-point unbalanced casting During casting, the distribution of the flow field of the profiled billet mold is extremely uneven. Due to the inhomogeneity of the flow field, the temperature field of the molten steel in the profiled billet mold is not uniform, and the cooling conditions of each surface of the mold vary greatly.

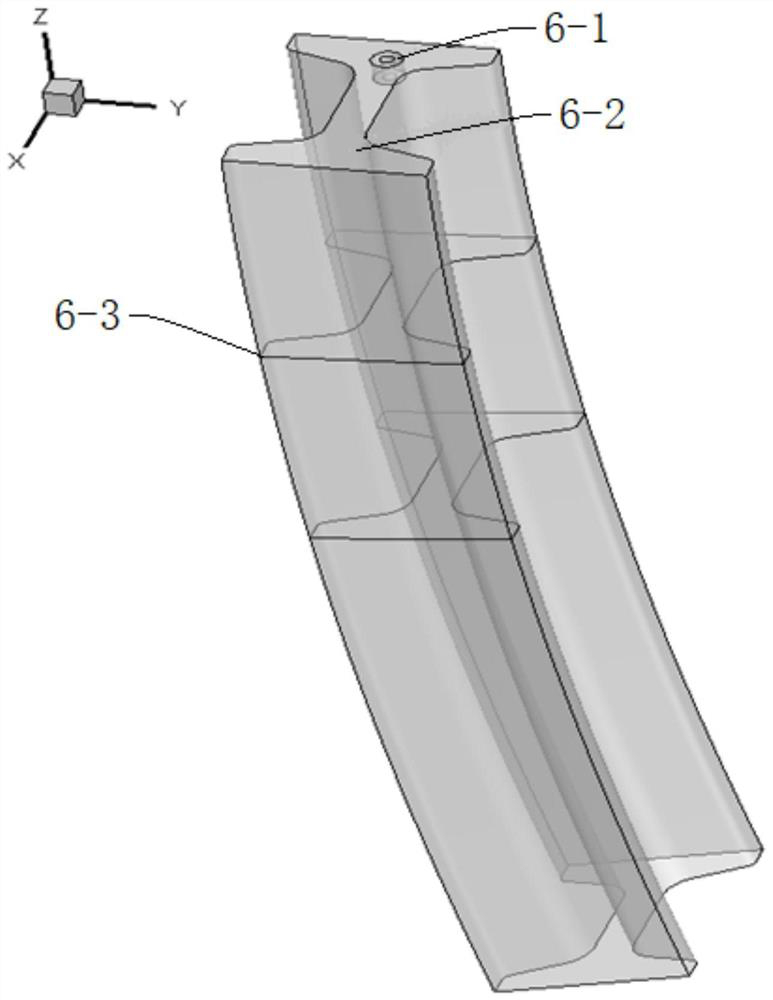

[0099] Such as figure 2 As shown, it is a schematic diagram of the mold for the special-shaped billet used by the control device and the control method of the present invention. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com