A selective laser melting additive manufacturing equipment

A technology of selective laser melting and additive manufacturing, which is applied in the directions of additive manufacturing, additive processing, and process efficiency improvement, and can solve the problems of insufficient forming efficiency of SLM technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

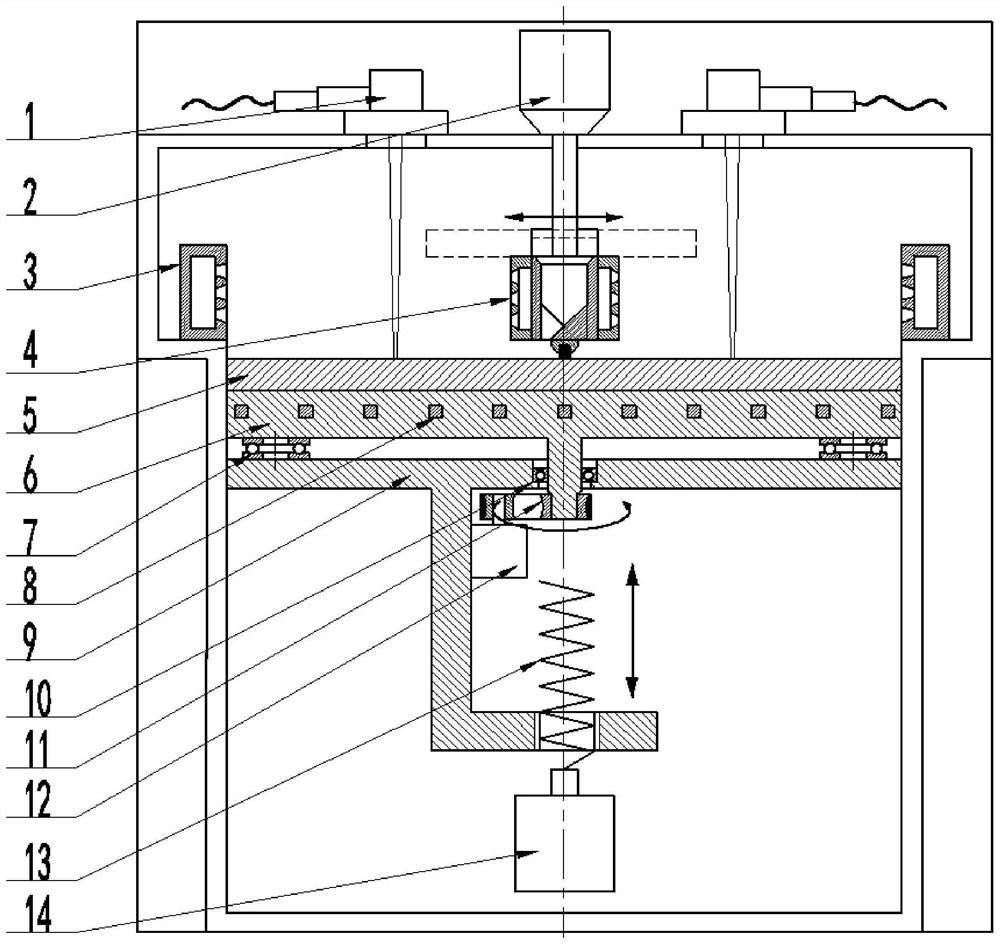

[0025] Laser melting additive manufacturing equipment of the present invention such as figure 1 shown. The equipment includes a point heat source laser vibrating mirror system 1; a powder supply system 2, a powder spreading device 4, a forming workbench system, and a smoke and dust circulation system.

[0026] The forming table system includes a base plate 5, a movable base 6, a thrust ball bearing 7, a preheating device 8, a fixed base 9, an angular contact ball bearing 10, a pulley mechanism 11, a small servo motor 12, a screw mechanism 13, Large Servo Motor14. The substrate 5 is fixed on the movable abutment 6; the movable abutment 6 is fixed on the fixed abutment 9 through a thrust ball bearing 7; the angular contact ball bearing 10 is connected with the movable abutment 6, and the small servo motor 12 passes through the angular contact ball The bearing 10 and the pulley mechanism 11 drive the movable base 6 to rotate at a uniform speed. The screw mechanism 13 is connec...

Embodiment 2

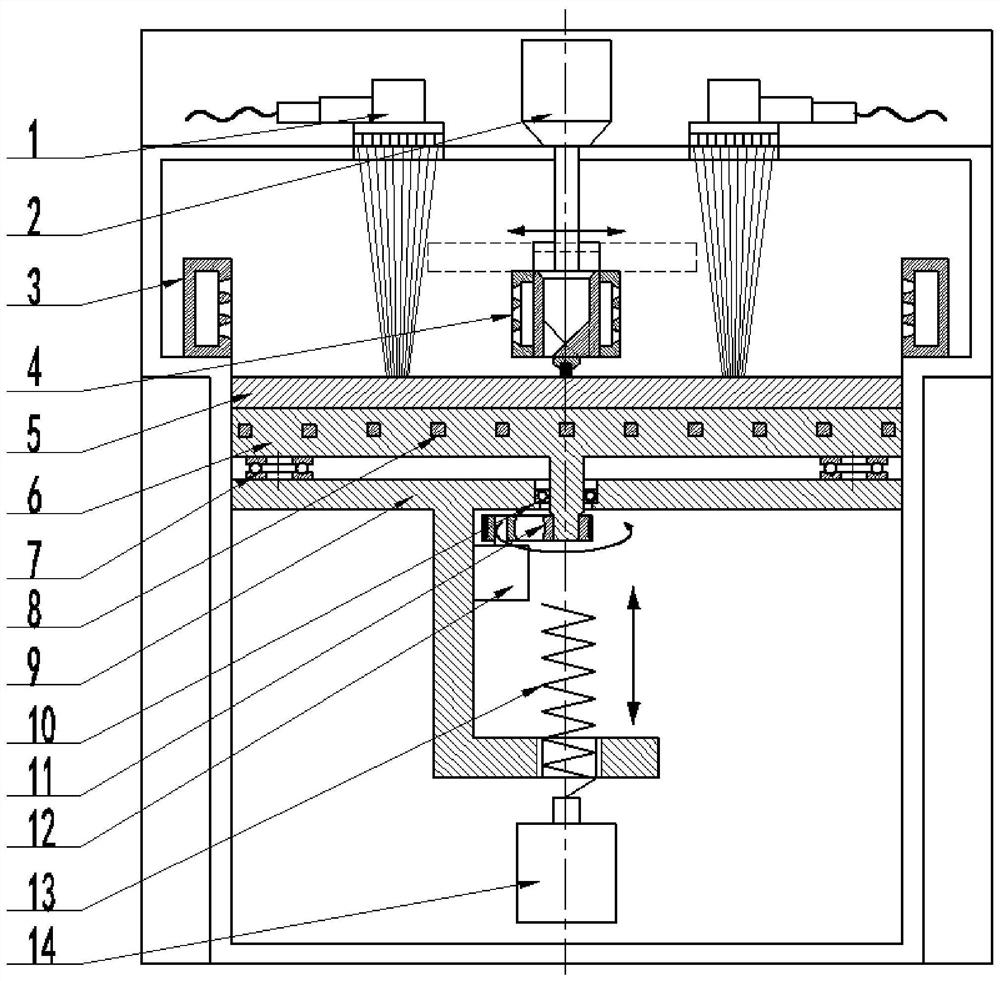

[0033] The selective laser melting additive manufacturing equipment of the present invention is as figure 2 shown. The equipment includes a line heat source laser vibrating mirror system 1; a powder supply system 2, a powder spreading device 4, a forming workbench system, and a smoke and dust circulation system.

[0034] The forming table system includes a base plate 5, a movable base 6, a thrust ball bearing 7, a preheating device 8, a fixed base 9, an angular contact ball bearing 10, a pulley mechanism 11, a small servo motor 12, a screw mechanism 13, Large Servo Motor14. The substrate 5 is fixed on the movable abutment 6; the movable abutment 6 is fixed on the fixed abutment 9 through a thrust ball bearing 7; the angular contact ball bearing 10 is connected with the movable abutment 6, and the small servo motor 12 passes through the angular contact ball The bearing 10 and the pulley mechanism 11 drive the movable base 6 to rotate at a uniform speed. The screw mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com