A method for cultivating and treating halophilic granular sludge from high-salt wastewater

A technology for high-salt wastewater and salt granules, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc. Sludge, increasing the difficulty of granulation of halophilic sludge, etc., to achieve the effect of various sources of sludge, shortening the treatment cycle and shortening the settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

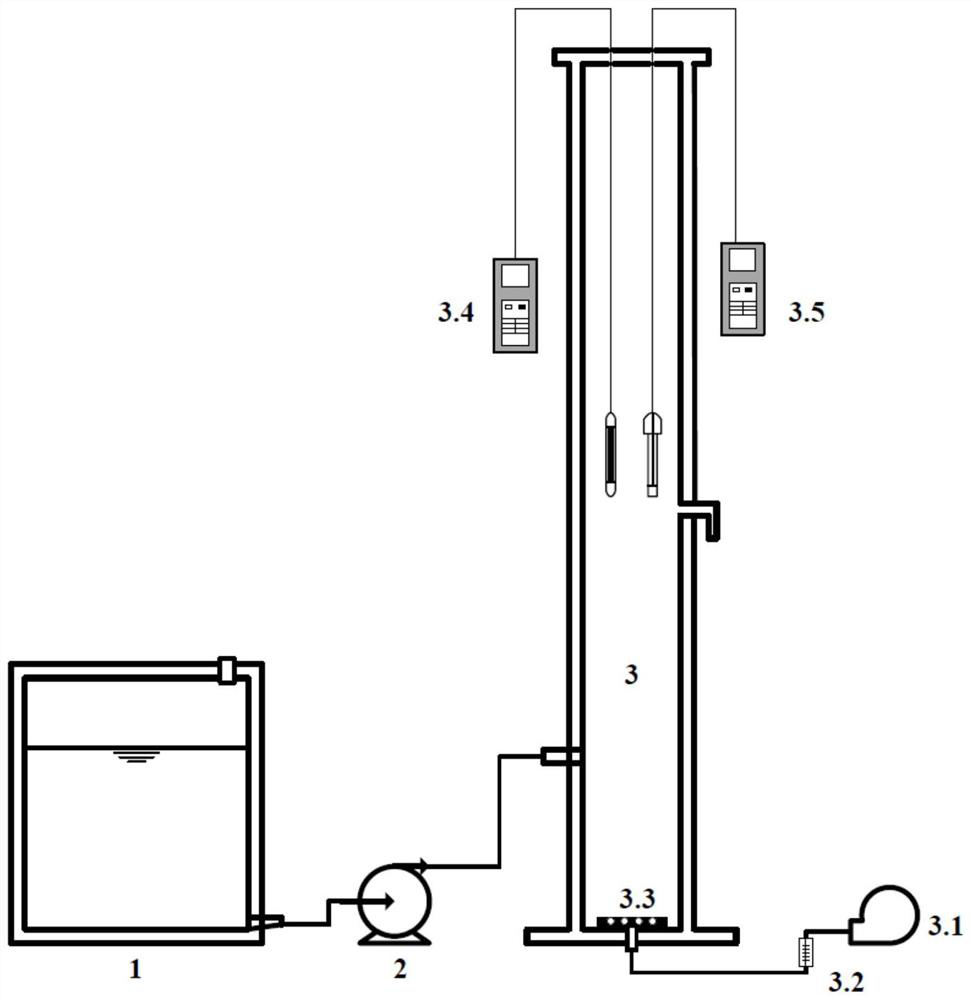

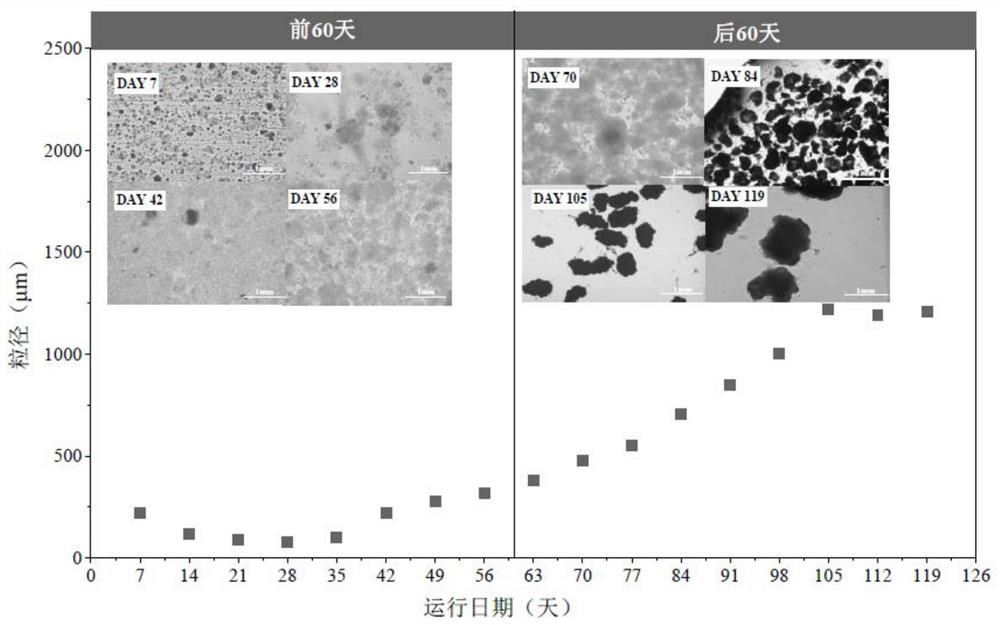

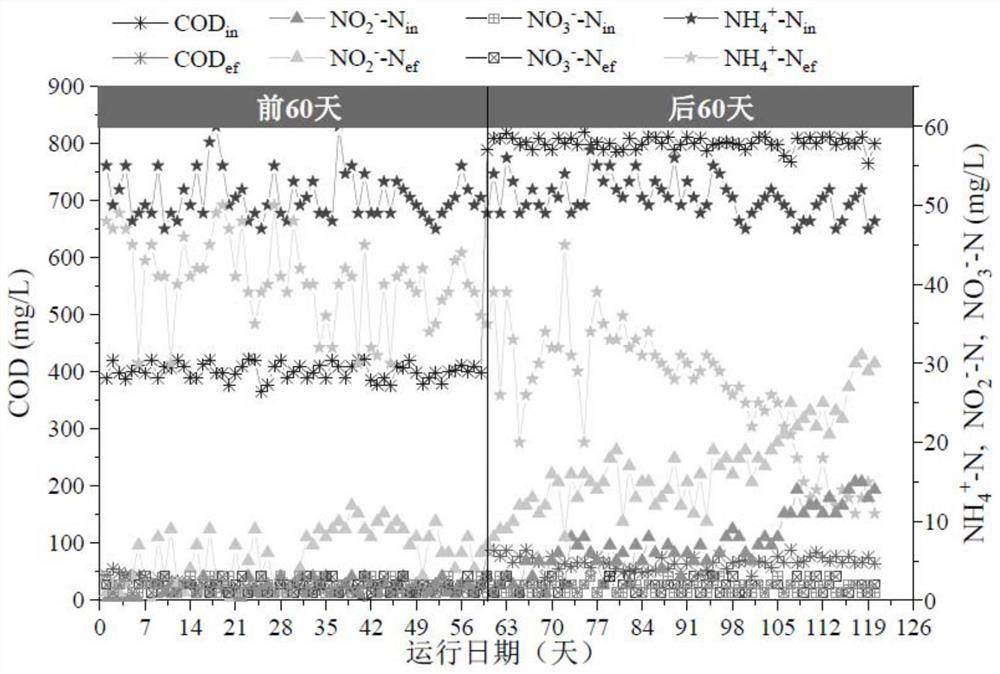

[0033] Step 1: Take 400m of sediment from the sea estuary of a certain city and inoculate it into the air-lift activated granular sludge SBR reactor (3) after pre-enrichment culture, and keep the volatile solid concentration at 3000mg / L.

[0034] Step 2: Inject domestic sewage into the raw sewage water tank (1), and add 30g / L coarse salt or sodium chloride to adjust the high-salt domestic wastewater to a salinity of 3%, as the raw influent for granulation cultivation. The COD concentration of the domestic sewage is 200-400mg / L, and the ammonia nitrogen concentration is 45-55mg / L.

[0035]Step 3: In the water inlet stage, the high-salt domestic wastewater configured in the raw water tank (1) is injected into the air-lift activated granular sludge SBR reactor (3) by using the water inlet peristaltic pump (2).

[0036] Step 4: Turn on the aeration pump (3.1) during the aeration stage, and send air to the aeration pan (3.3) through the connecting pipeline. Adjust the gas flow met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com