Method for reducing surface roughness of heating plate subjected to shot blasting

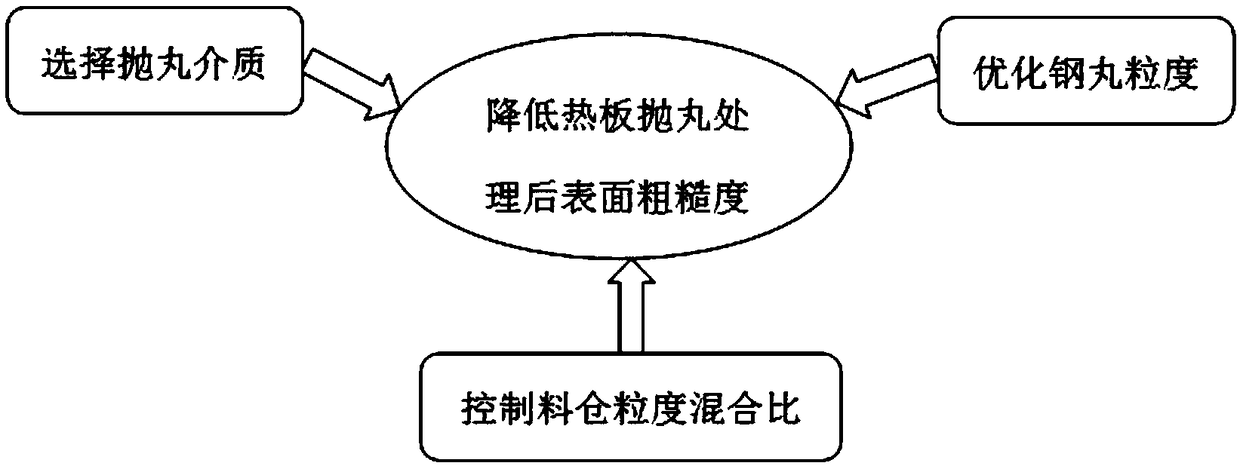

A back surface and roughness technology, applied in the field of stainless steel rolling, can solve the problems of unable to meet market demand, high surface roughness of hot plate, lack of shot blasting process, etc., to save shot blasting medium, reduce surface roughness, The effect of reducing the effective particle content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] In the method for reducing the surface roughness after the hot plate shot blasting treatment in the embodiment of the present invention, high-carbon cast steel shot is selected as the shot blasting medium, and the particle size of the steel shot is as shown in the above table 1, and the steel shot is placed in the shot blasting machine. The particle size mixing ratio of the silo in the silo is controlled so that particles with a nominal size of 0.3mm account for about 17%; particles with a size above 0.5mm are less than 5%. Using the method for reducing the surface roughness of the hot plate after shot blasting treatment in this embodiment, the surface roughness Ra of the cold plate after the shot blasting treatment can be reduced from 3.5 μm to 3.1 μm, and the consumption of shot blasting medium per ton of steel is also reduced by 2.06Kg / ton of steel dropped to 1.88Kg / ton of steel, a drop of 8.7%.

[0048] The beneficial effects of the method for reducing the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com