Full-automatic rock core intelligent cutting machine and method for cutting rock core with same

A fully automatic, core technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of manual operation, etc., and achieve the effect of convenient cleaning and collection, reducing work intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

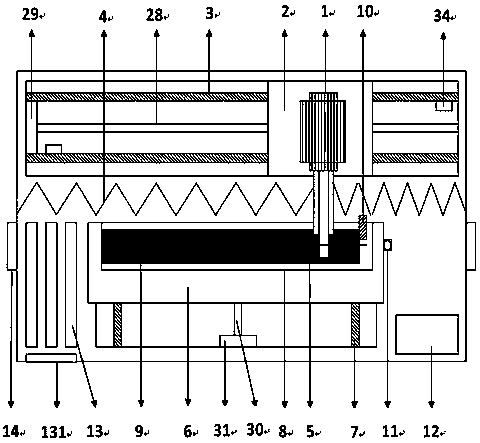

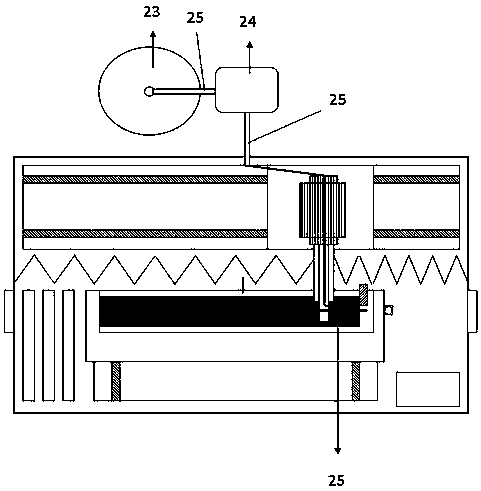

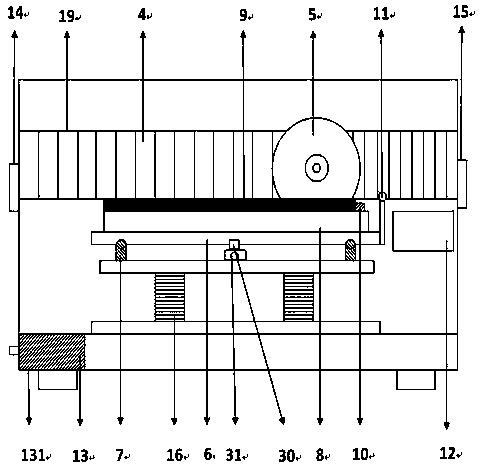

[0035] Such as Figure 1-5 As shown, the fully automatic intelligent core cutting machine includes a frame system, a cutting device, a core workbench system, a circulating liquid cooling device, a control device, and an exhaust and dust removal device.

[0036] The frame system includes a vertical plate 18; a square hole 19 is arranged horizontally at a certain height on the vertical plate 18, and a foldable stainless steel sheet 4 is installed on the square hole 19; a longitudinal installation hole 20 is provided on the foldable stainless steel sheet 4.

[0037] Described cutting device comprises main motor 1, cutter table 2, transverse guide rail 3, cutting blade 5; On the knife workbench 2, the cutter workbench 2 is installed on the slide block of the transverse guide rail 3 and the slide block is connected with the transverse motion driving device; the power output shaft 21 of the main motor 1 is installed on the longitudinal installation of the folding stainless steel she...

Embodiment 2

[0055] Such as Figure 1-5 As shown, the difference between this embodiment and Embodiment 1 is that the core holder 8 can hold rock cores 9 of different diameters, and supports double cutting blades for cutting.

[0056] The fully automatic intelligent core cutting machine consists of a cutting device, a core holding device, a core workbench, a circulating liquid cooling device, a control device, and an exhaust device. The overall shell is made of stainless steel.

[0057] The cutting device is composed of main motor, cutter table, guide rail, cutting blade and so on. The main motor is a servo motor installed on the cutter workbench, which is installed on the guide rail. The lead screw drives the workbench to move back and forth on the guide rail, and the servo motor drives the lead screw to rotate; the front and rear directions of the core workbench are driven by the motor. The screw moves; the control of each motor and other parts of the equipment is controlled by the PLC...

Embodiment 3

[0066] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that two cutting blades 5 are installed on the power output shaft 21 of the main motor 1, and an adjustable The spacer ring 26 of two cutter spacings.

[0067] The fully automatic intelligent core cutting machine consists of a cutting device, a core holding device, a core workbench, a circulating liquid cooling device, and a control device. The overall shell is made of stainless steel. The cutting steps are as follows.

[0068] 1. First turn on the power switch on the control device, and the fixed laser source 11 on the core working platform 6 will be automatically turned on. According to the lithology, length, and diameter of the core, use the control touch LCD screen 12 to set the appropriate speed of the cutting tool , working speed, core cutting length and other parameters.

[0069] The starting position of the rock core working platform 6 is near the position near the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com