Ring-pull can recycling bin

A technology of pop-top cans and recycling bins, applied in garbage collection, household appliances, applications, etc., can solve the problems of unrealistic, consumption, and complicated conveyor belt structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

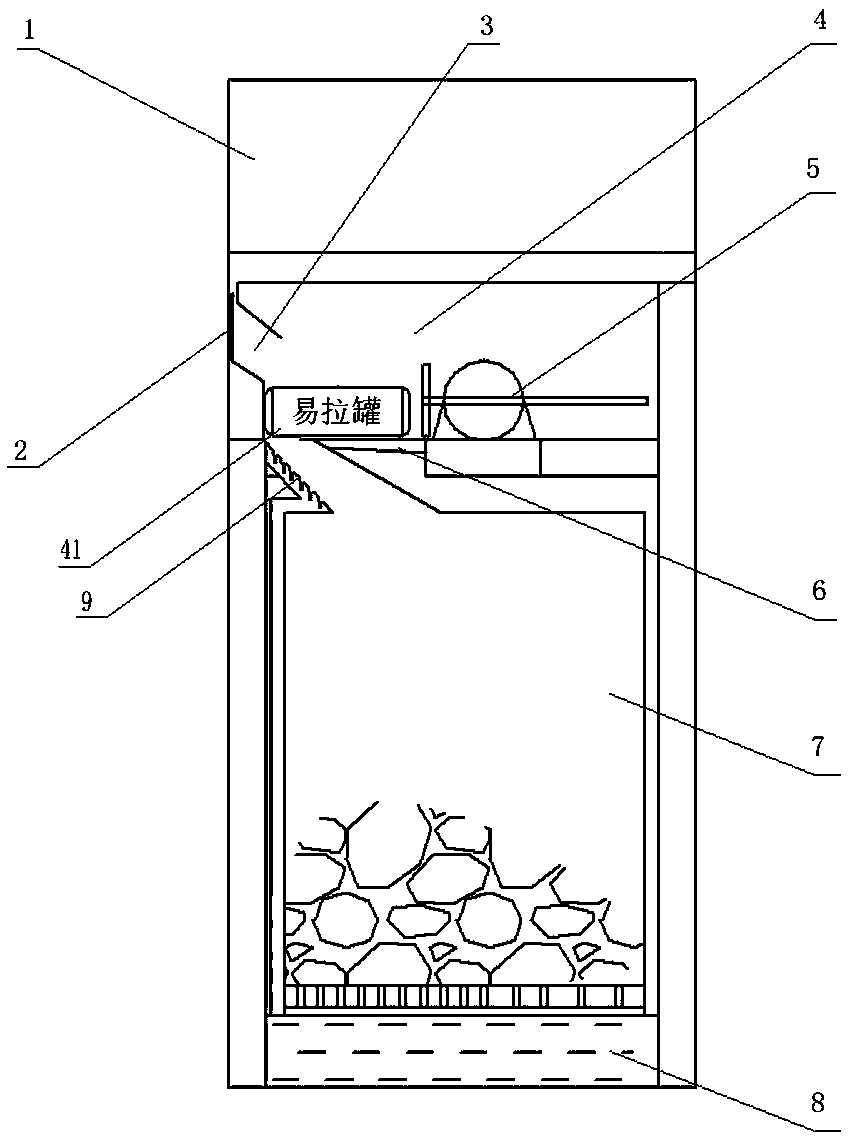

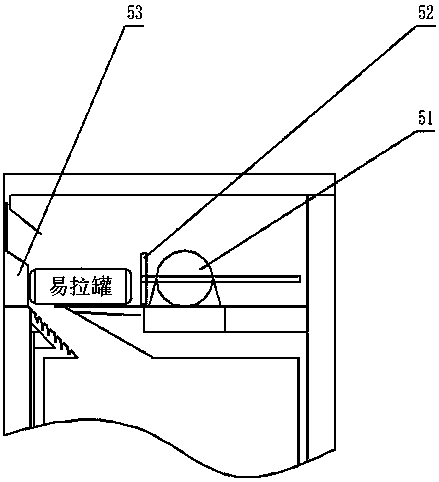

[0015] see figure 1 , a pop can recovery box, comprising a shell box 1, the shell box 1 is provided with a pop can delivery opening 2, the diameter of the pop can delivery opening 2 is 7 cm, and is used for putting in metal pop cans, and the pop can delivery opening 2 is provided with a sensor The door, the sensor door includes a door panel, a sensor module and a drive device, to prevent foreign objects from flying out when handling the equipment and to prevent children's hands from reaching into the opening when handling soda cans.

[0016] The door panel is a semi-circular turntable, the center of which is fixed above the inside of the can opening 2. The semi-circular turntable itself can be rotated. Usually due to gravity, the semi-circle turntable will naturally rotate to the bottom to cover the can opening 2. The center of the circular turntable is provided with a gear, and the sensing module is arranged around the pop cans delivery port 2 and can be an ultrasonic sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com