Medical drug material conveying omega-shaped spectacle plate and bolt closed transmission system

A transmission system, double-hole plate technology, applied in conveyors, transportation and packaging, etc., can solve the problems of standardization of conveying equipment manufacturing, difficulty in repair and maintenance, increase in chain distance, etc., to achieve easy installation and disassembly, and service life. Long, low contact stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

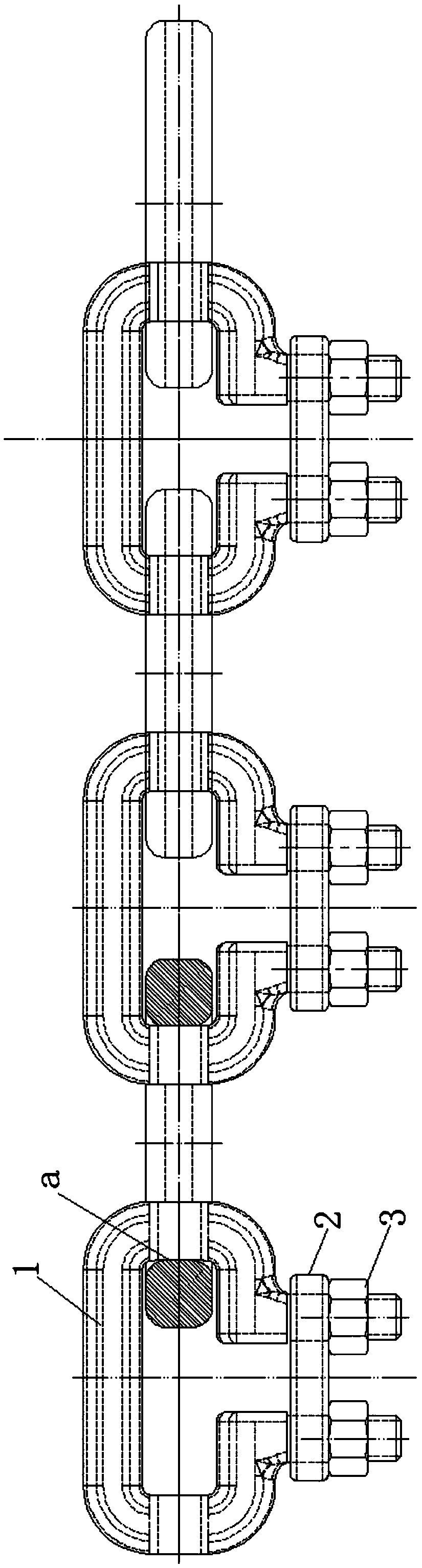

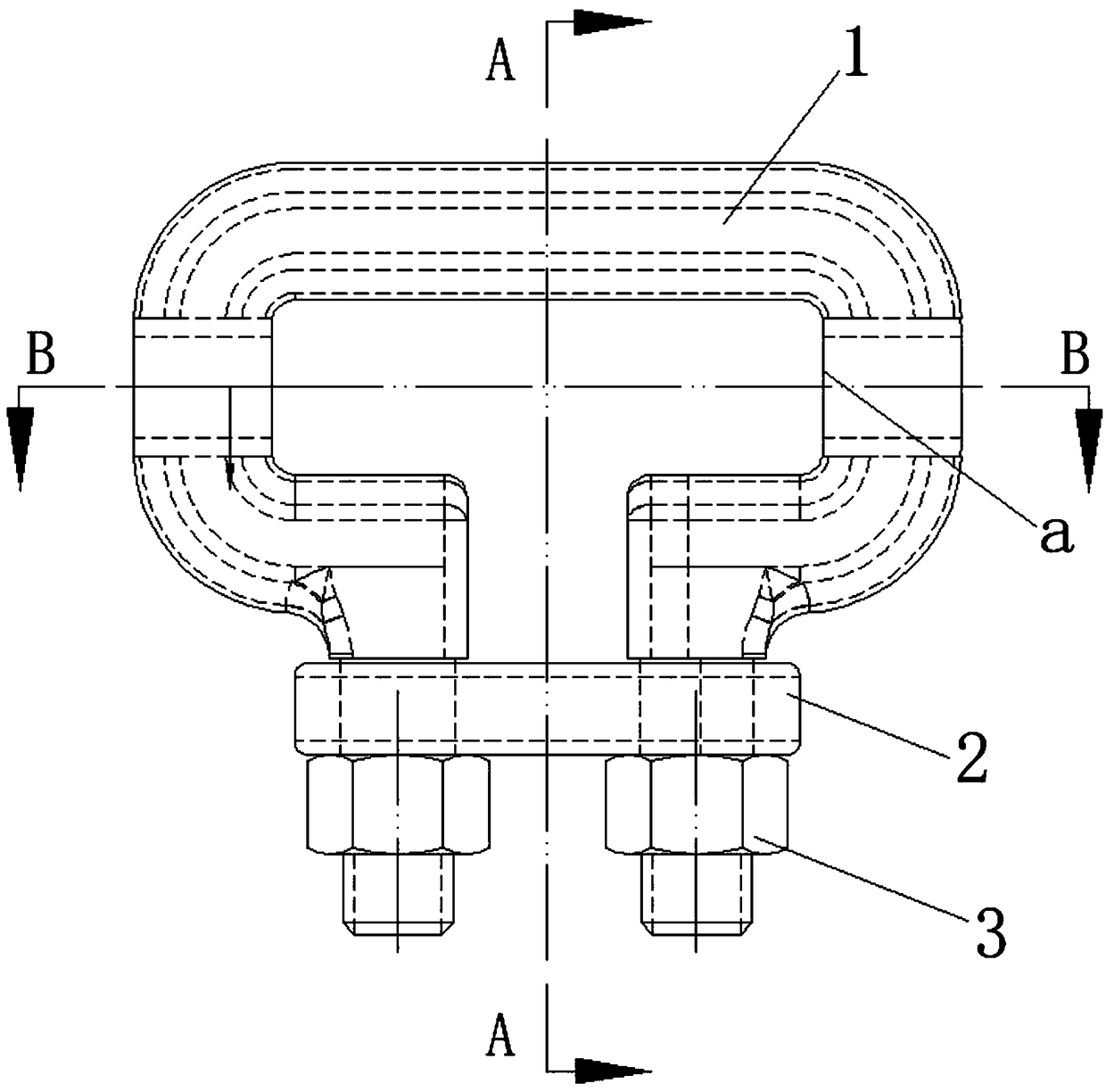

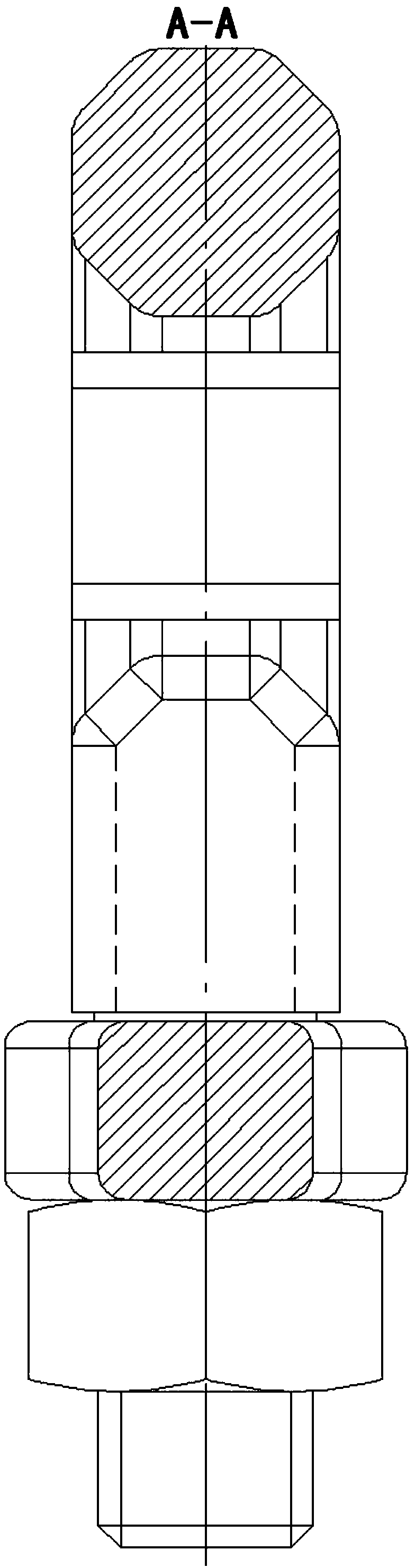

[0016] exist Figure 1 ~ Figure 4 Among them, the Ω-shaped double-hole plate and bolt-enclosed transmission system for medical drug material transportation in the present invention is composed of chains formed by vertically placed and horizontally placed Ω-shaped closed links alternately connected to each other; the Ω-shaped closed links are connected The position is a plane a, and the connection between them is in surface contact; the Ω-shaped closed link includes an Ω-shaped body 1 with threads at the end, a double-hole plate 2 installed on the end of the Ω-shaped body, and the double-hole plate is tightened. Fastened to the fastening nut 3 on the omega-shaped body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com