A hoisting method for boiler rear roof superheater components

A hoisting method and superheater technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of long construction period and high installation cost, and achieve the effects of shortened construction period, fast assembly speed and high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0066] The boiler of the 2×350MW unit in this example is a supercritical parameter variable pressure operation once-through furnace produced by Shanghai Boiler (Group) Co., Ltd., single furnace, primary reheat, balanced ventilation, open air layout, solid slag discharge, all-steel frame, full suspension Hanging structure Π type boiler. The boiler superheated steam flow rate is 1172t / h, the superheated steam outlet pressure is 25.4MPa, the superheated steam outlet temperature is 571℃; the reheated steam flow rate is 962t / h, the reheated steam inlet and outlet pressure is 5.4 / 5.22MPa, and the reheated steam inlet and outlet temperature is 343 / 569. ℃; The design thermal efficiency is 93.9%.

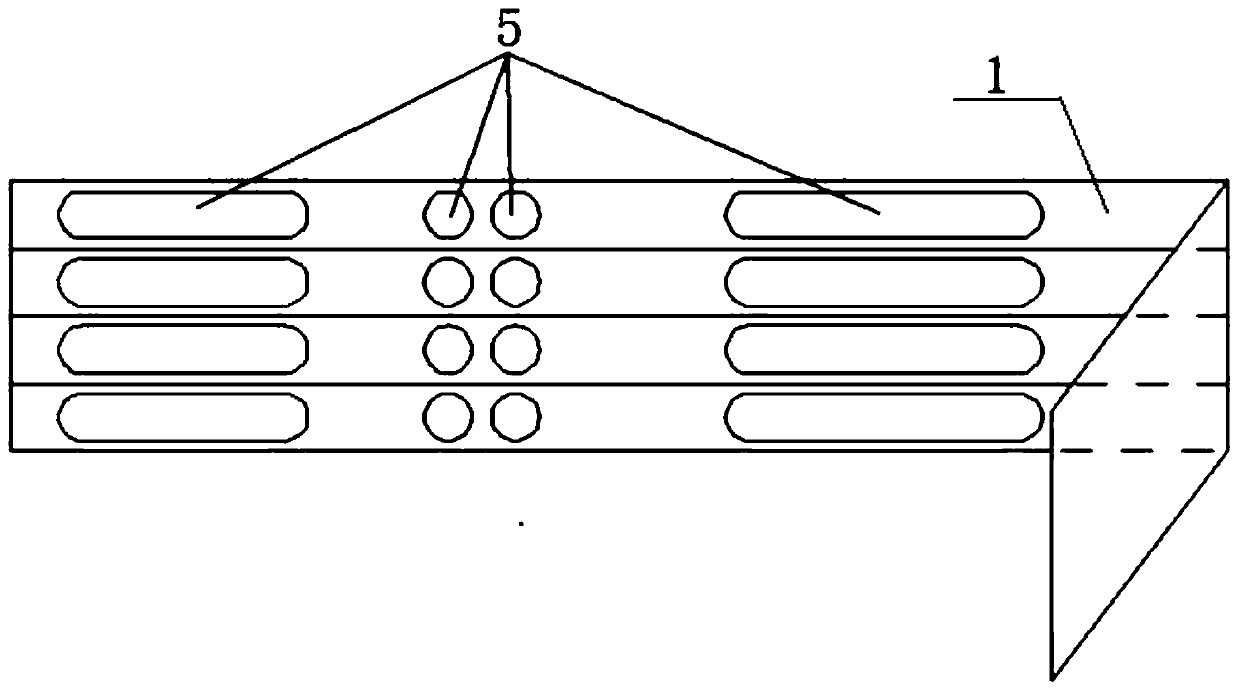

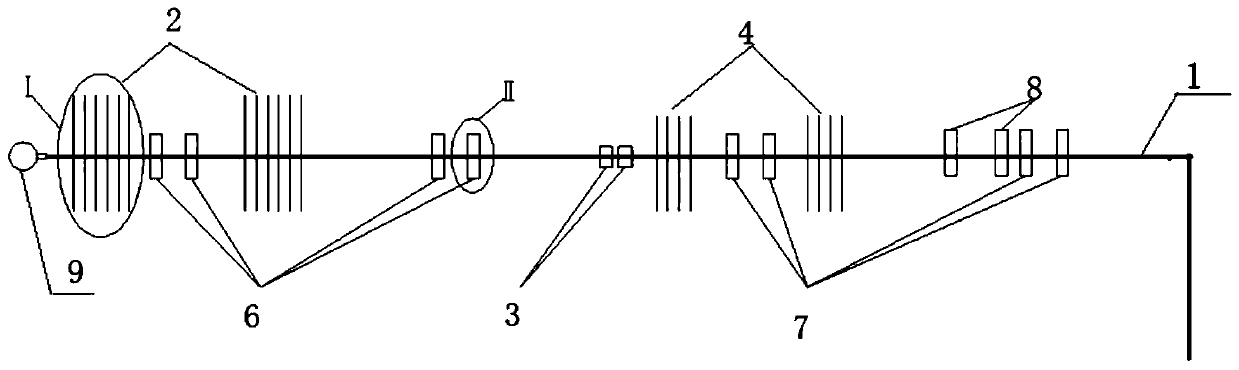

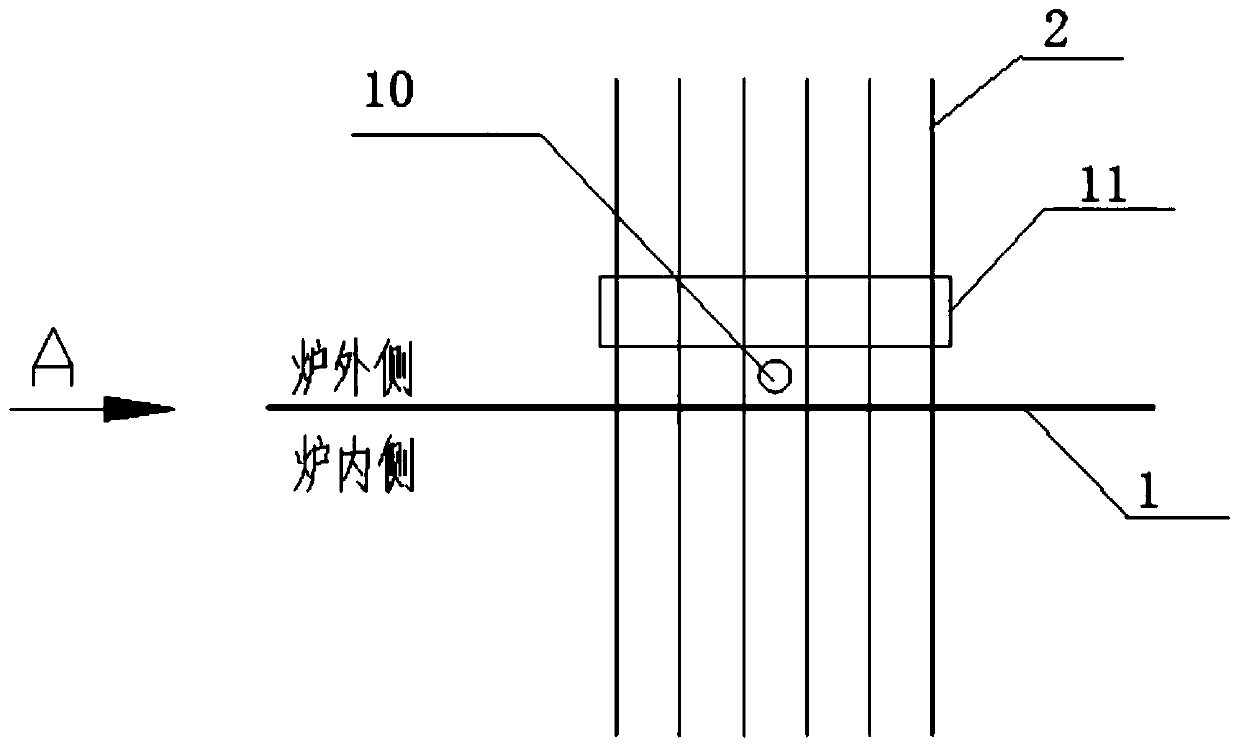

[0067] The boiler superheating system is divided into front top superheater, rear top superheater, wall superheater, low temperature superheater, panel superheater, final stage superheater, and the rear top superheater is arranged on the top of the flue gas area of the back smoke well , Nume...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com