Production method of low-cost and high-performance structural steel

A technology for structural steel and production methods, which is applied in the manufacture of converters, etc., can solve problems such as poor processability, uneven hardness, and low strength, and achieve the effects of improving mechanical properties, improving processing performance, and high carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Composition design

[0027] The design chemical composition of Q345B-JG steel is:, C: 0.14~0.19%, Si: 0.05~0.25%, Mn: 0.90~1.30%, P≤0.025%, S≤0.008%, Als: 0.010~0.060%, Nb : 0.007~0.018%, the balance is Fe and unavoidable impurities.

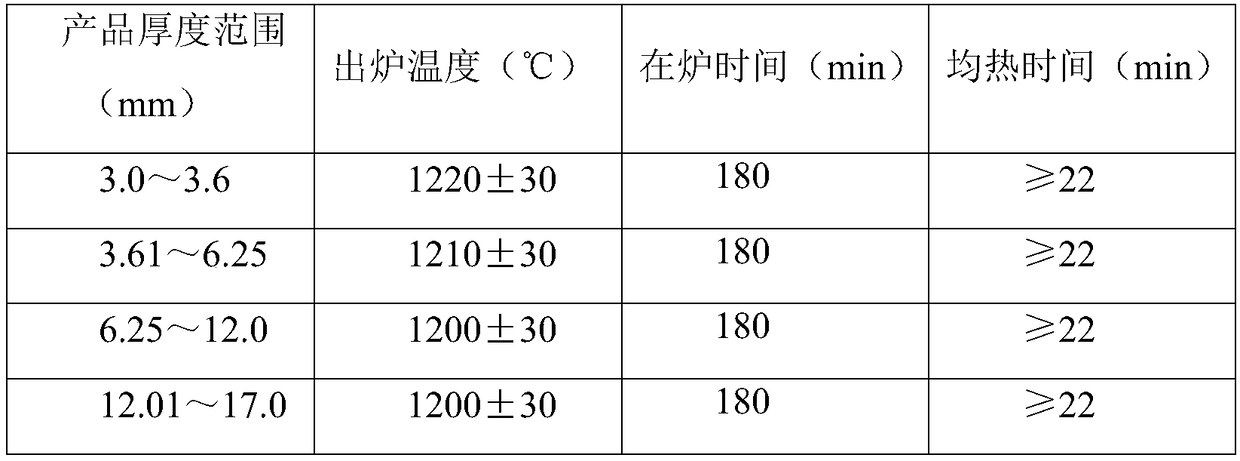

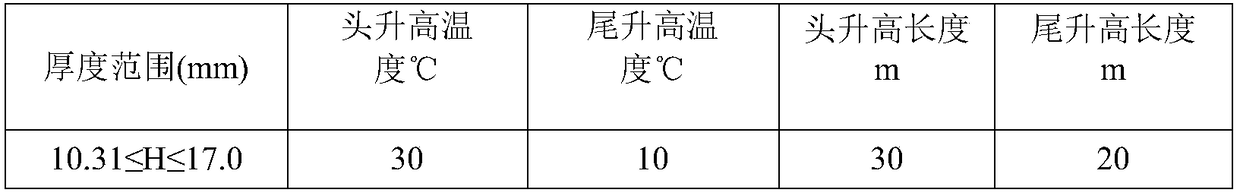

[0028] The production process is as follows: desulfurization of molten iron, converter blowing, LF and AR refining, continuous casting, hot direct loading, soaking, rough rolling, finish rolling, laminar cooling, coiling, and cooling to the factory.

[0029] (2) Smelting technology

[0030] Desulfurization of molten iron to [S]≤0.008%;

[0031] Bottom blowing in converter smelting adopts nitrogen-argon switching; tapping slag and steel tapping, strictly controlling the amount of slag in the converter; tapping alloying with addition of Si, Mn alloys and recarburizers; ladle bottom blowing of argon is required to be good;

[0032] The continuous casting adopts full protection casting; the liquidus temperature TL=1514°C, and the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com