Concrete for quick pavement repair

A technology for concrete and concrete slurry, applied in the field of concrete, can solve the problems of secondary cracking, frequent maintenance and repair by construction personnel, and easy detachment of concrete, and achieves the effects of fast setting time, fast and convenient electric operation, and reinforcement and adhesion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

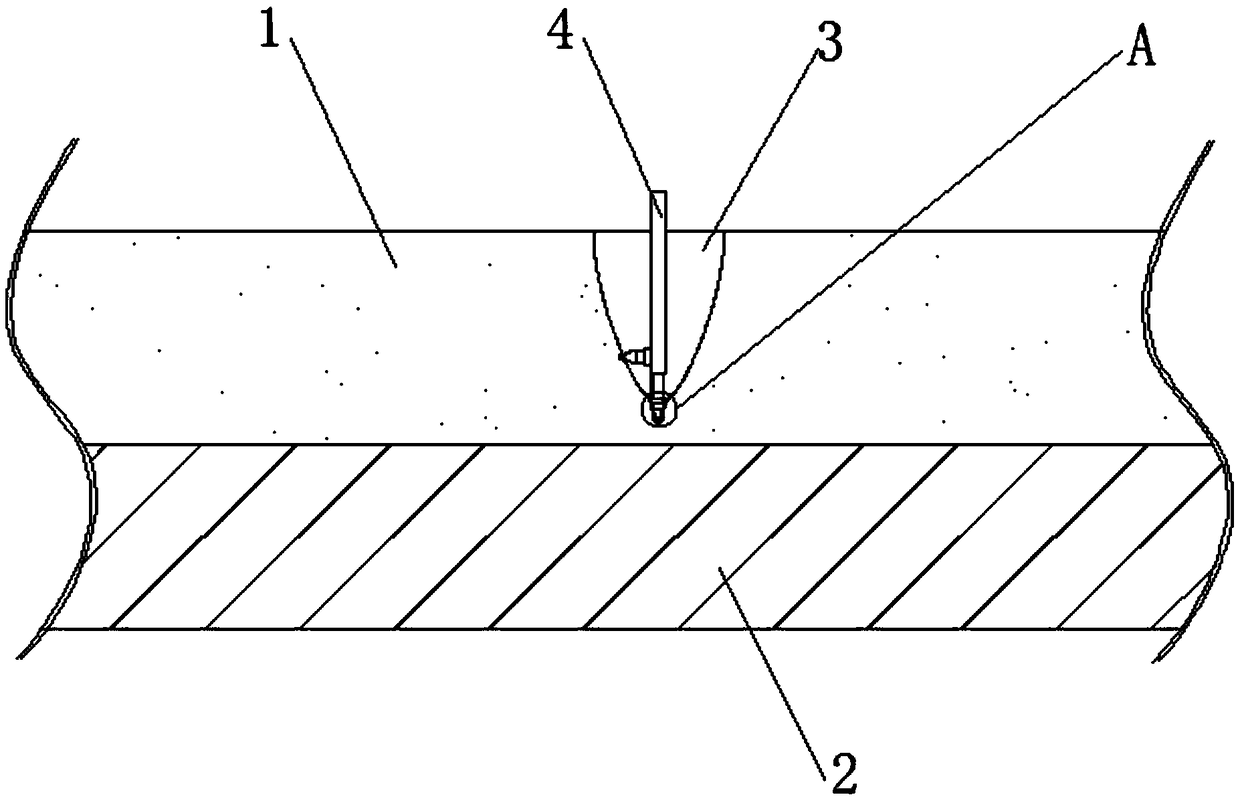

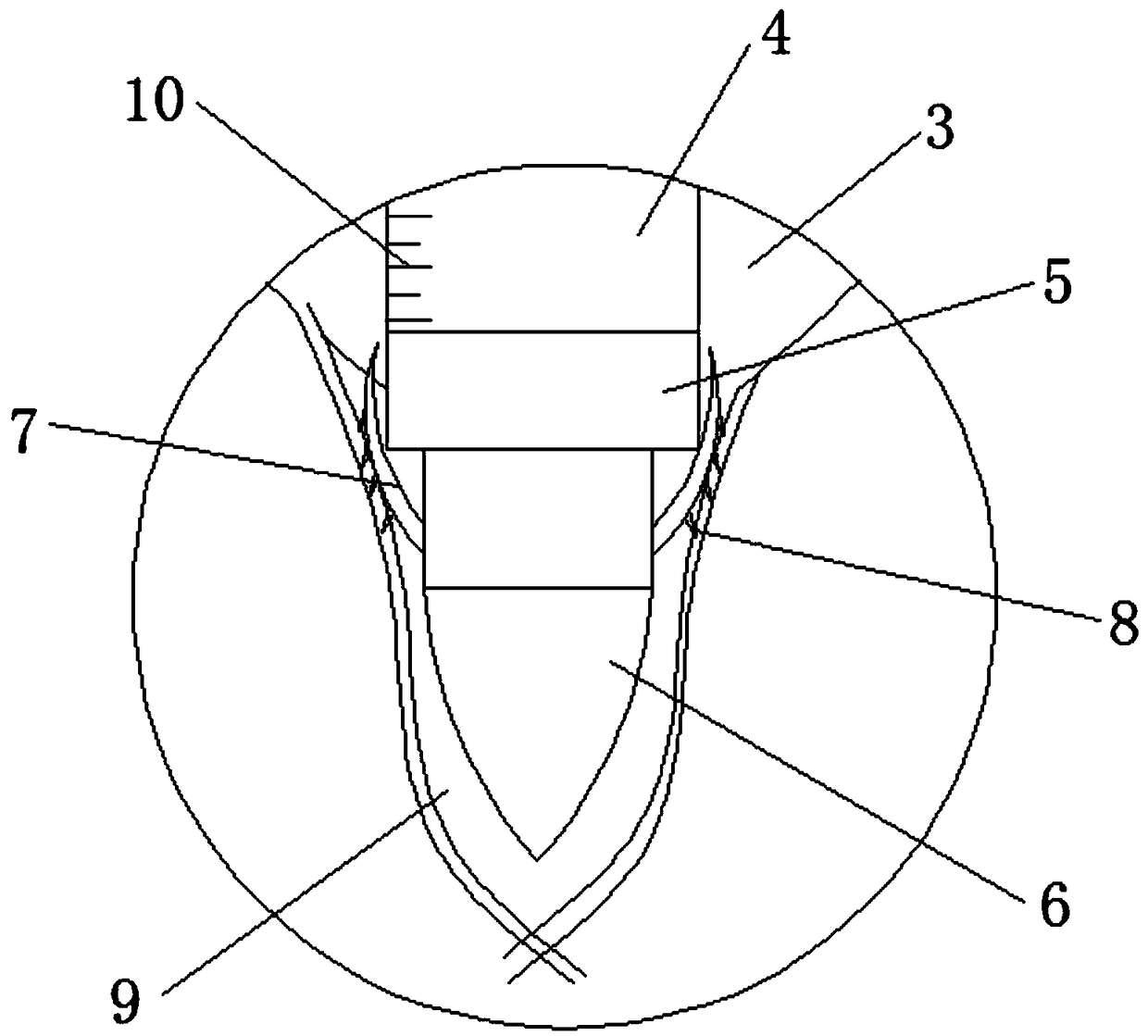

[0058] see Figure 1-9 , a kind of concrete for pavement rapid repair, comprising concrete slurry 13 and pavement 2 with original concrete layer 1 laid on the upper surface, crack 3 is arranged on the original concrete layer 1, concrete slurry 13 fills in crack 3, concrete slurry 13 fills crack 3 Crack 3 needs to be artificially reconstructed before crack 3 is located. Manual reconstruction requires the use of a reconstruction operating device. Before concrete and other repair materials are poured into crack 3, crack 3 is reconstructed to improve the adhesion of concrete and other repair materials to crack 3. The repair materials such as concrete will not easily break away from cracks 3, which greatly reduces the number of repairs.

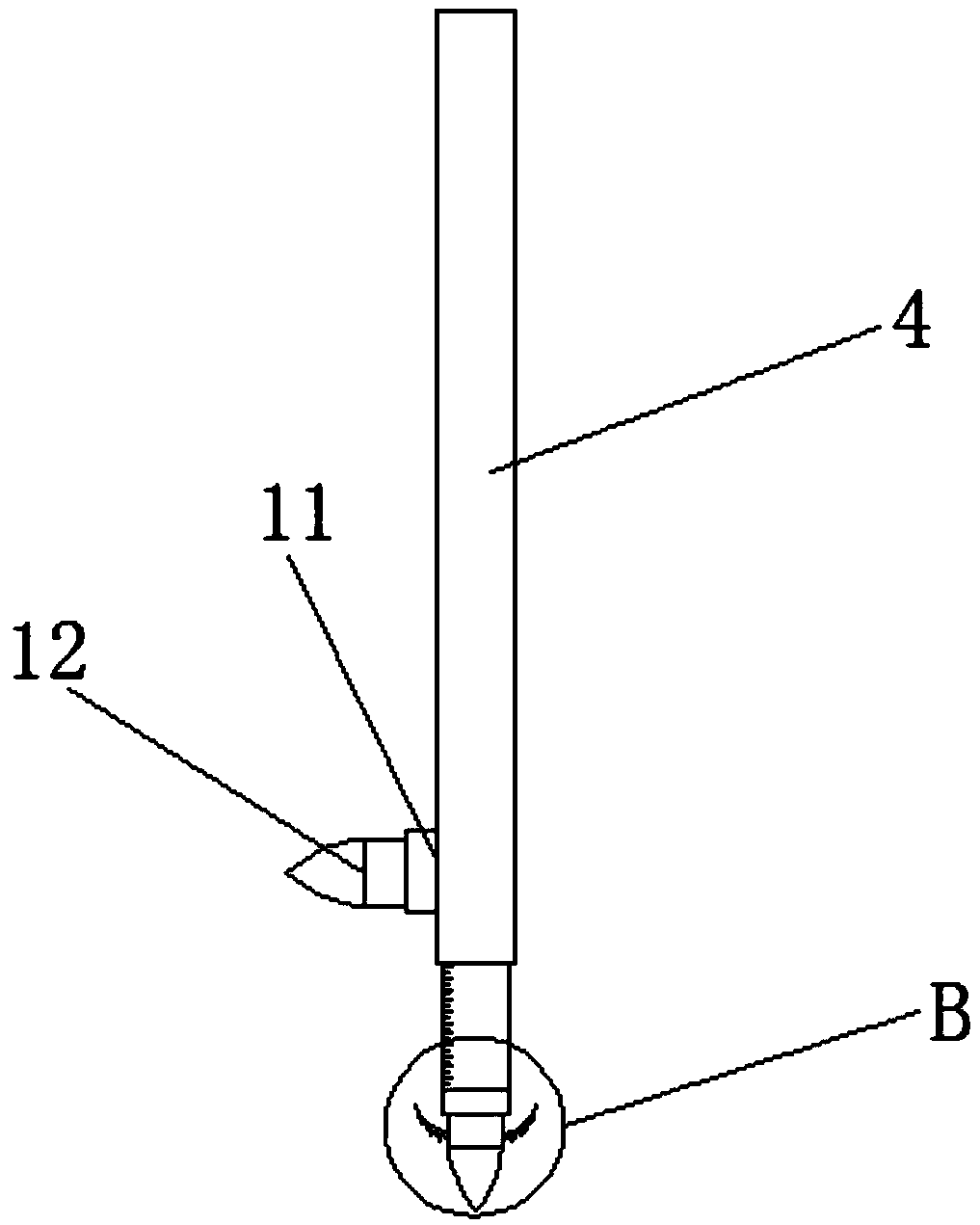

[0059] The transformation operation device includes an operating rod 4, a first drilling device and a second drilling device. The first drilling device and the second drilling device are respectively located at the bottom end and the side end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com