Neutral non-flowback circular scale-removing technological process suitable for ternary combination flooding rod pumping well

An oil pumping well and ternary compound technology, applied in the ternary field, can solve the problems of static scale cleaning agent without convection, excess and uneven reaction agent, low acid scale reaction efficiency, etc., so as to accelerate the scale dissolution reaction process and improve the contact Reaction efficiency, the effect of improving the utilization rate of the agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

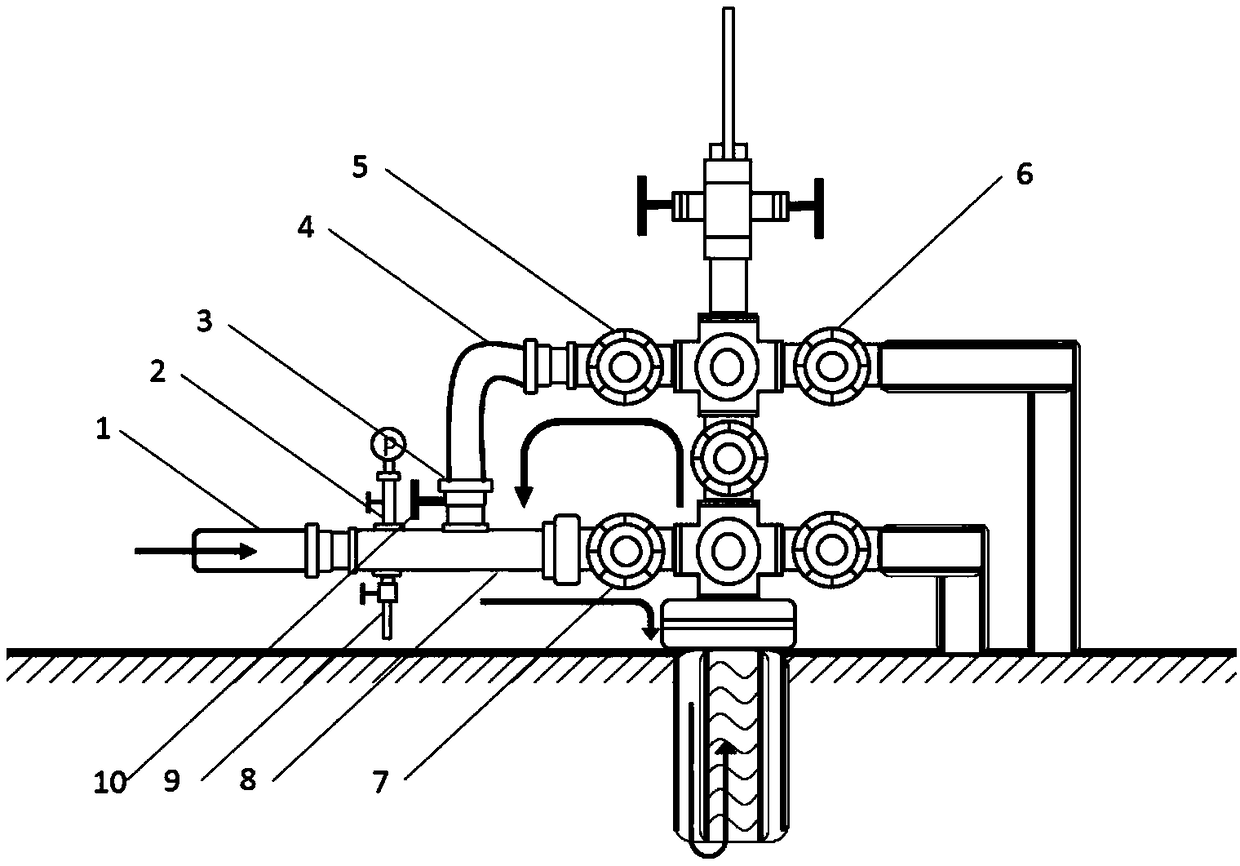

[0024] Specific embodiments: The present invention will be further described below in conjunction with the accompanying drawings: it consists of a high-pressure injection pipeline 1, a pressure monitoring joint 2, a three-way controller circulation joint 3, a high-pressure hose 4, an oil pipe venting valve 5, an oil pipe production valve 6, a sleeve Tube vent valve 7, three-way controller 8, sampling vent valve 9, and circulation interface valve 10; the casing vent valve 7 is connected to the three-way controller 8, and the three-way controller is connected to the oil pipe through high-pressure hose 4 through 8 Vent valve 5, a neutral non-flowback cycle cleaning process suitable for ASP flooding pumping wells, is realized through the following steps:

[0025] a. Pumping unit shut down

[0026] If it is judged that the well uses an open pump, stop the donkey head to the top dead point; if a conventional plunger pump is used, stop the donkey head to the bottom dead point, open t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com