Experimental device for vibration dynamics modal test

A modal test and experimental device technology, applied in vibration testing, measuring devices, testing of machine/structural components, etc., can solve the problems of complex design, complicated change and disassembly, single excitation point, etc., to achieve convenient disassembly, shape The effect of good applicability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

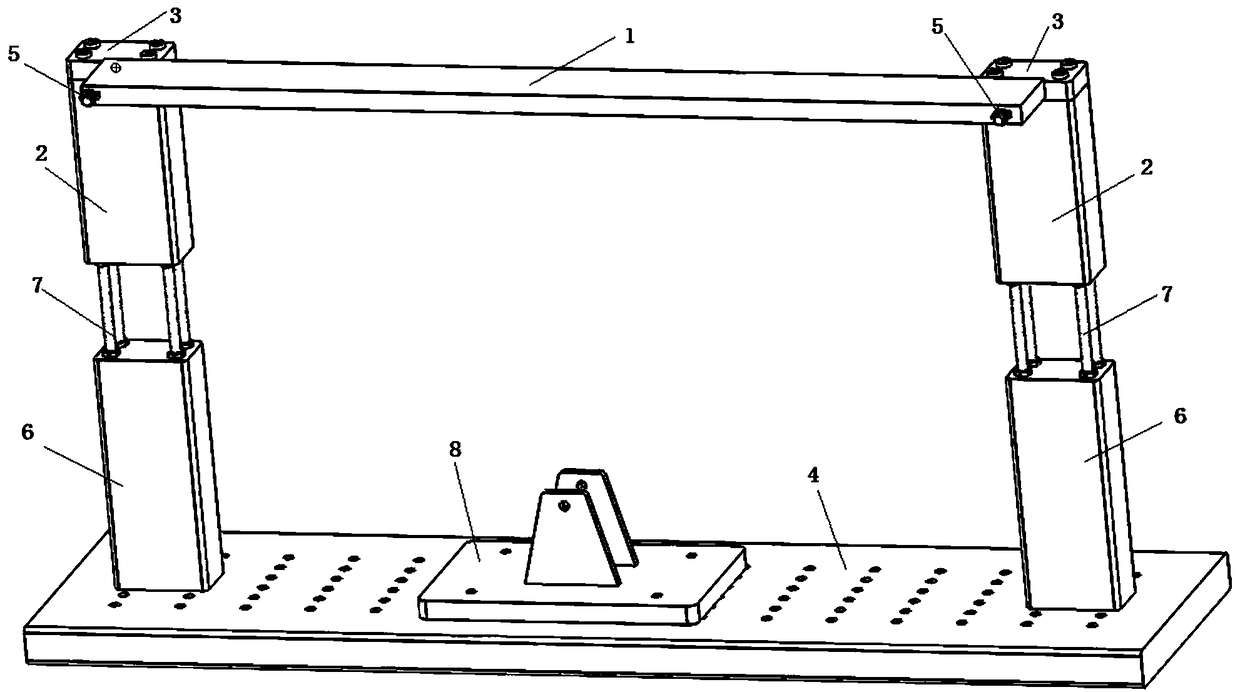

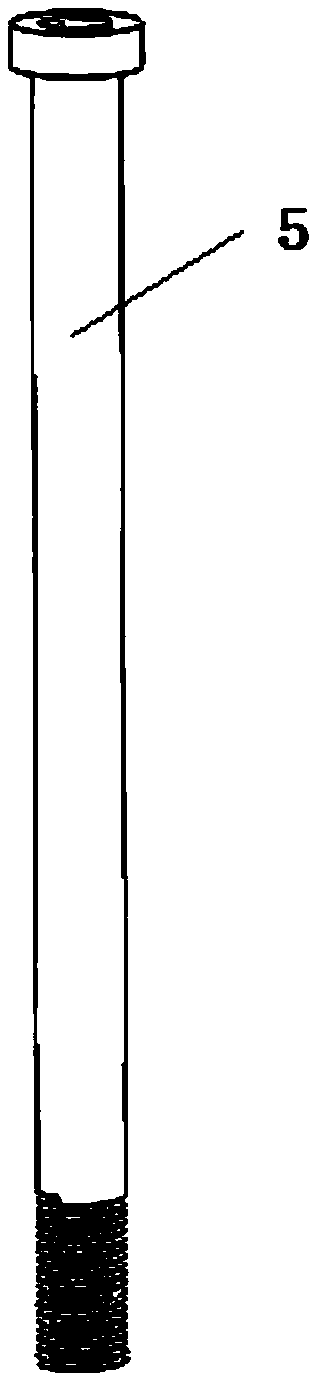

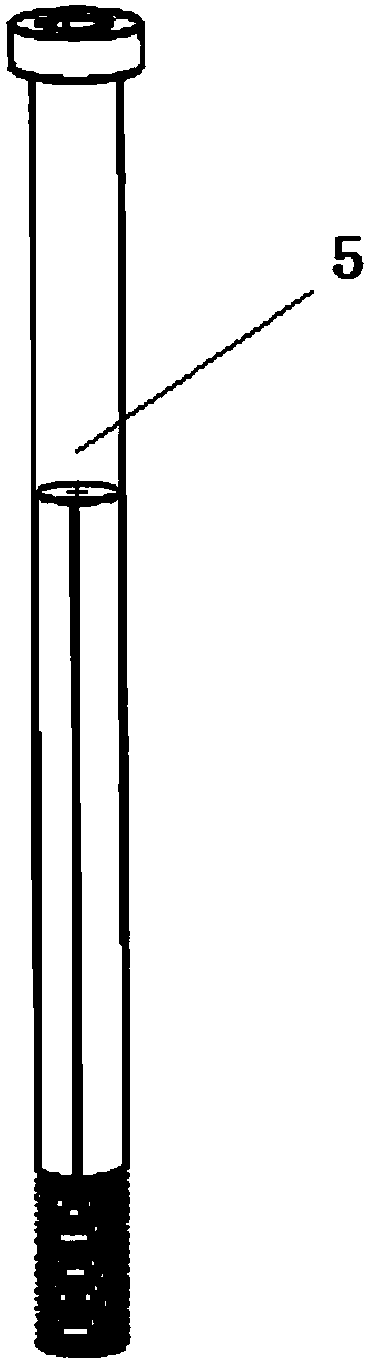

[0022] Such as figure 1 As shown, the present invention includes an experimental model (in this embodiment, a horizontal experimental steel beam 1 is selected), a beam end clamp, a height-adjustable base column and an experimental base floor 4, wherein square holes are preset at both ends of the horizontal experimental steel beam There are two groups of beam end clamps, each set of beam end clamps includes clamp upper block 3 and clamping rod 5, the cross section of the clamping rod of the first set of beam end clamps is square, and the clamping rod of the second set of beam end clamps The cross-section of the holding rod is circular, and threads matching the bolt caps are provided at the end of the holding rod, such as figure 2 , 3 shown.

[0023] The clamp upper block of each set of beam end clamps is connected with the horizontal experimental steel beam through the clamping rod and the bolt cap. Hole slots are joined in an inscribed form. When the clamping rod with squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com