Visualized crack grouting test device and method for simulating multiple main control variables

A technology of grouting test and grouting device, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as low hydrostatic pressure, lack of grout diffusion and migration rules, and lack of effective control of water environment pressure in aquifers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

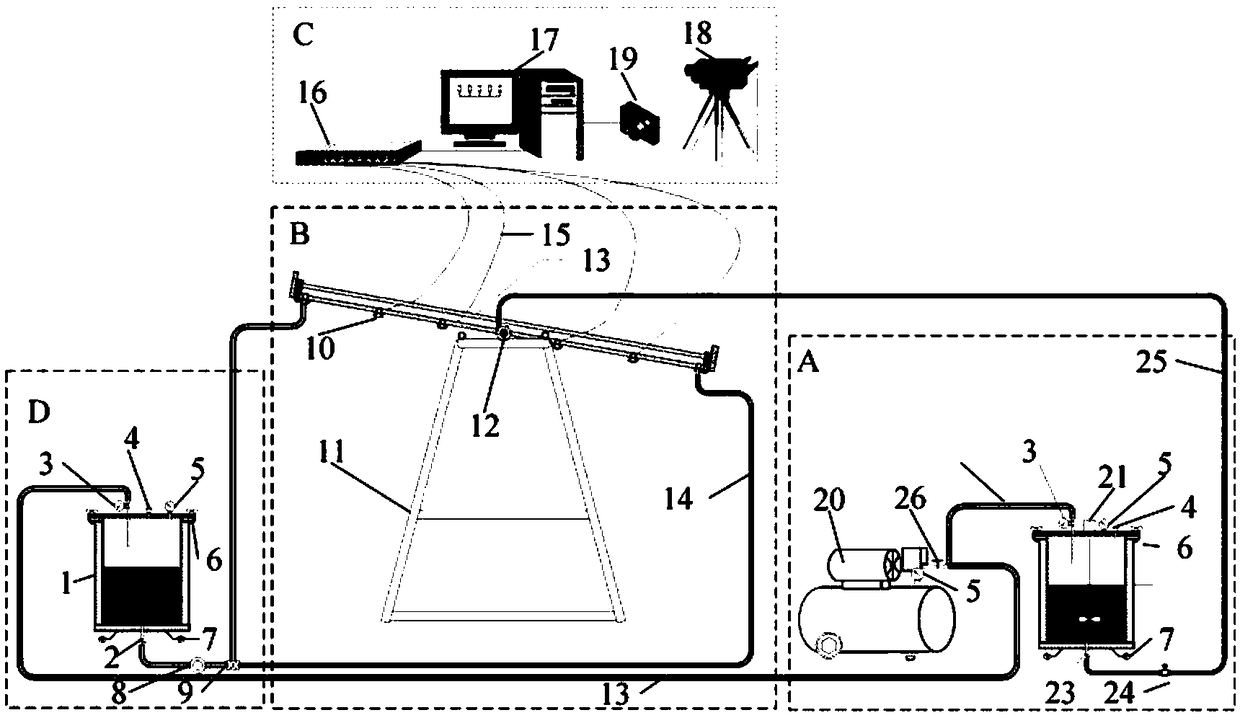

[0048] figure 1 The overall schematic diagram of the Ming experimental device in the embodiment of the present invention is illustrated.

[0049] Please refer to figure 1 , a visual fissure grouting test device for simulating multiple main control variables, including four major systems: A hydraulic constant system, B visual fissure grouting platform, C data acquisition and analysis system, D grouting system.

[0050] The four systems are described below in conjunction with the accompanying drawings.

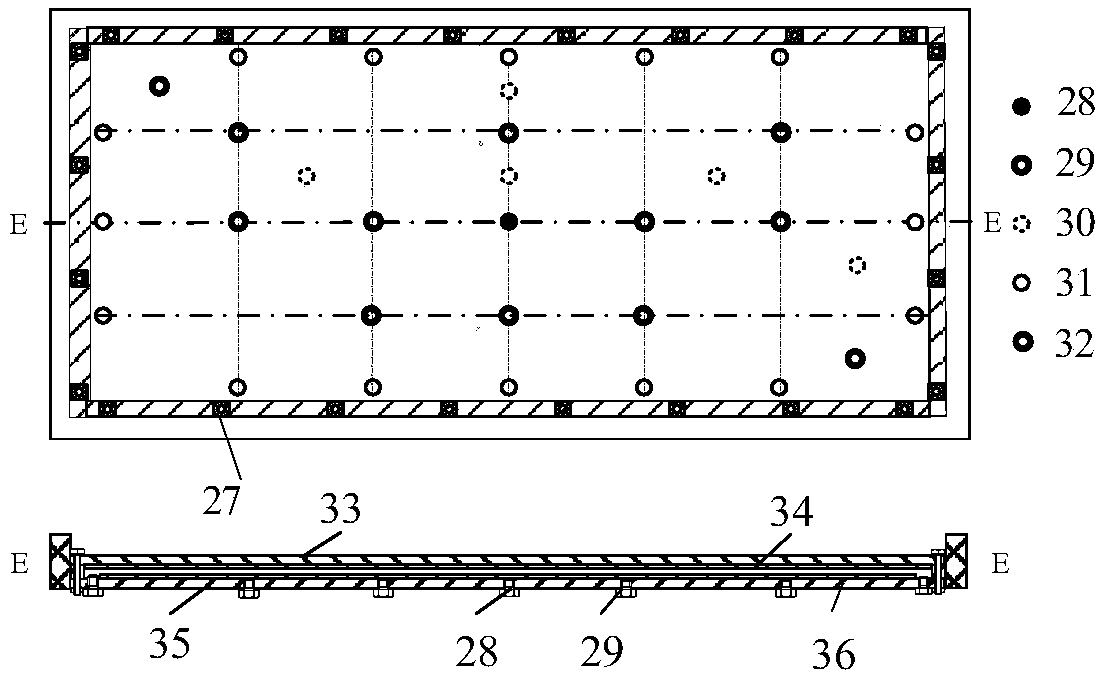

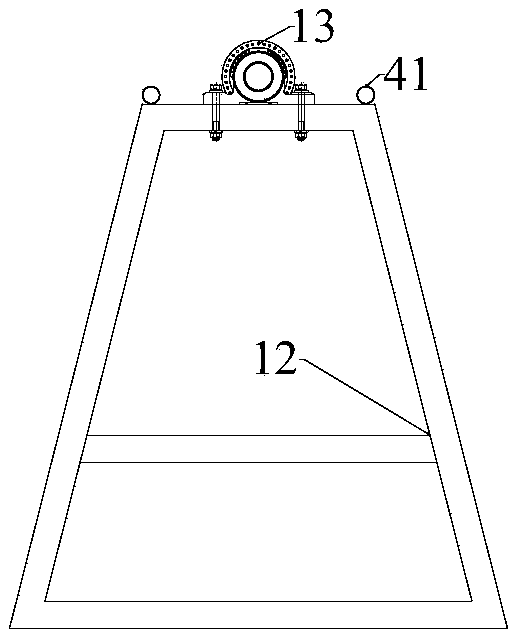

[0051] Such as Figure 2-4 As shown, the visual fissure grouting platform includes: upper cover layer, lower bottom plate, sealing strip, screw fasteners, plate fissure placement base, and angle adjuster. Among them, the upper cover layer has two layers. The first layer of the upper cover is made of plexiglass plate, and its length, width and height are respectively: 1300×700×20mm. The second layer of the upper cover is artificial raw rock film, and its length, width and heig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com