A method for predicting the temperature rise of transformer hot spots by comparing optical fiber temperature measurement

A technology of optical fiber temperature measurement and prediction method, which is applied in the field of electrical insulation on-line monitoring and fault diagnosis, which can solve the problems of overall insulation damage, operation and maintenance difficulties, and damage of windings, and achieve online monitoring, accurate and fast batch prediction, and strong robustness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the drawings and specific implementation process. It should be emphasized that the specific implementation cases described here are only used to explain the present invention, and do not limit the scope of the inventive concept and the claims thereof.

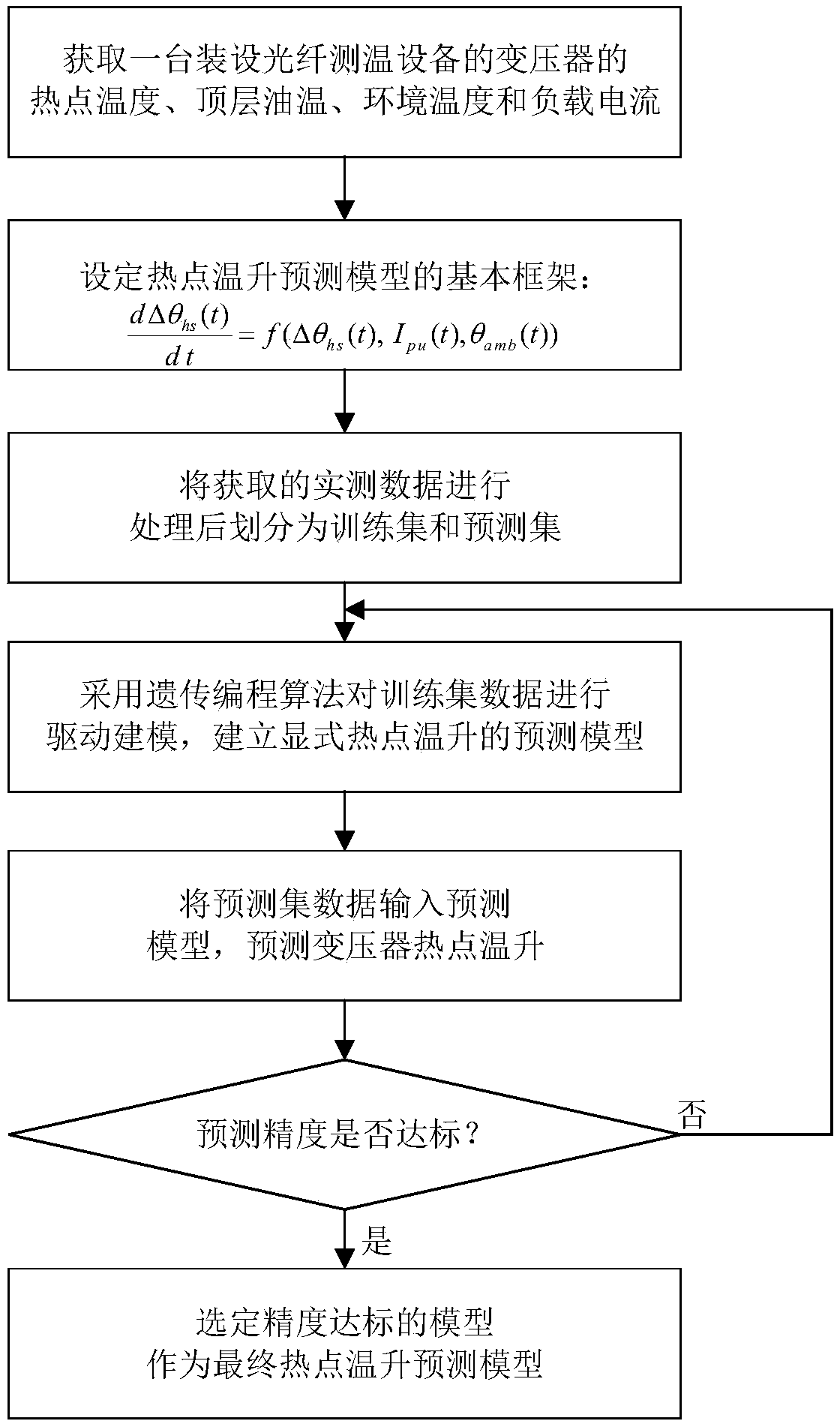

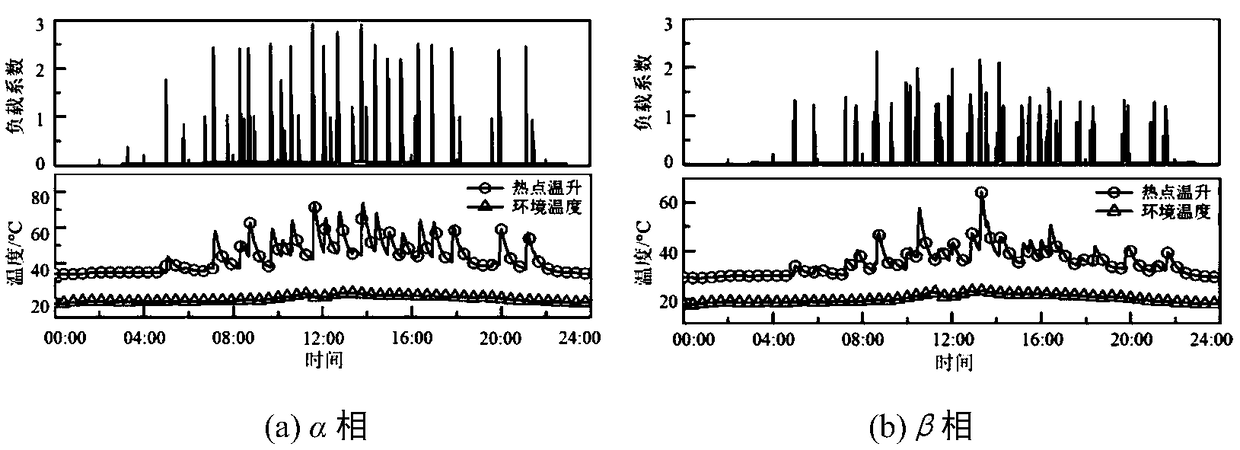

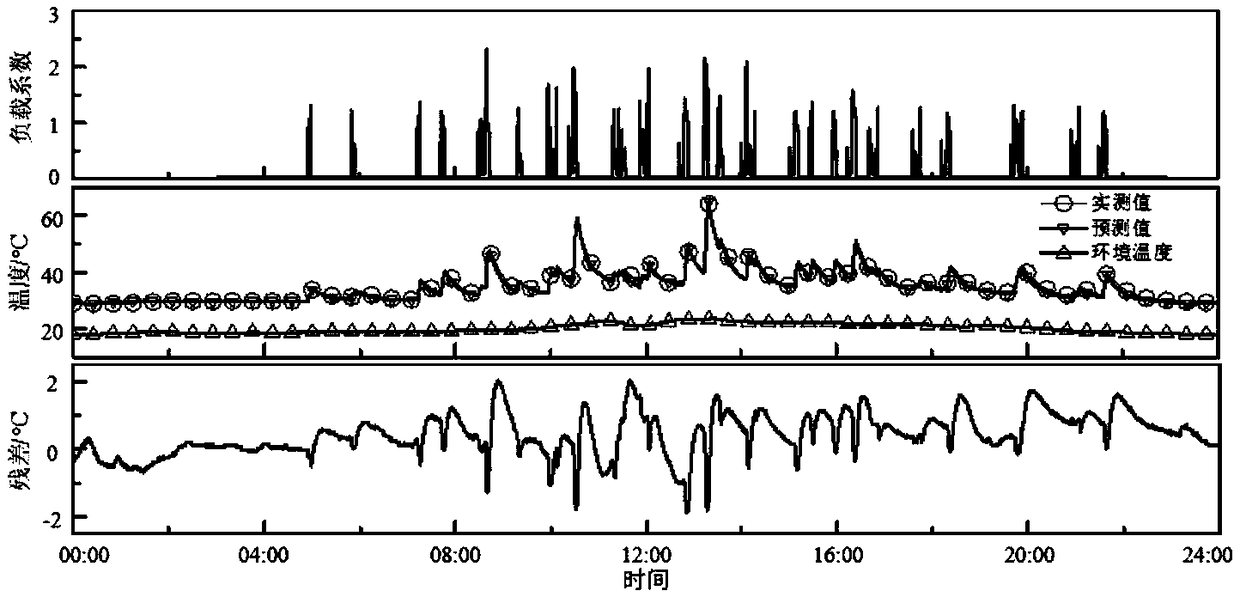

[0046] Taking the hot spot temperature rise, load current and ambient temperature data of traction transformer A installed with optical fiber temperature measurement equipment in a traction substation as an example, and predicting the hot spot temperature rise of transformer B in different sections of the same line ,details as follows:

[0047] The first step is to obtain the measured hot spot temperature, top oil temperature, ambient temperature, and load current data of the α-phase and β-phase traction transformer A equipped with optical fiber temperature measurement equipment:

[0048]The nameplate parameters of traction transformer A are shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com