An intelligent layout optimization algorithm for shipyard assembly yard

An intelligent optimization algorithm and optimization algorithm technology, applied in calculations, calculation models, instruments, etc., can solve problems such as the inability to guarantee efficient utilization of resources, the impractical implementation of site allocation, and the lack of quantification of the general team site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

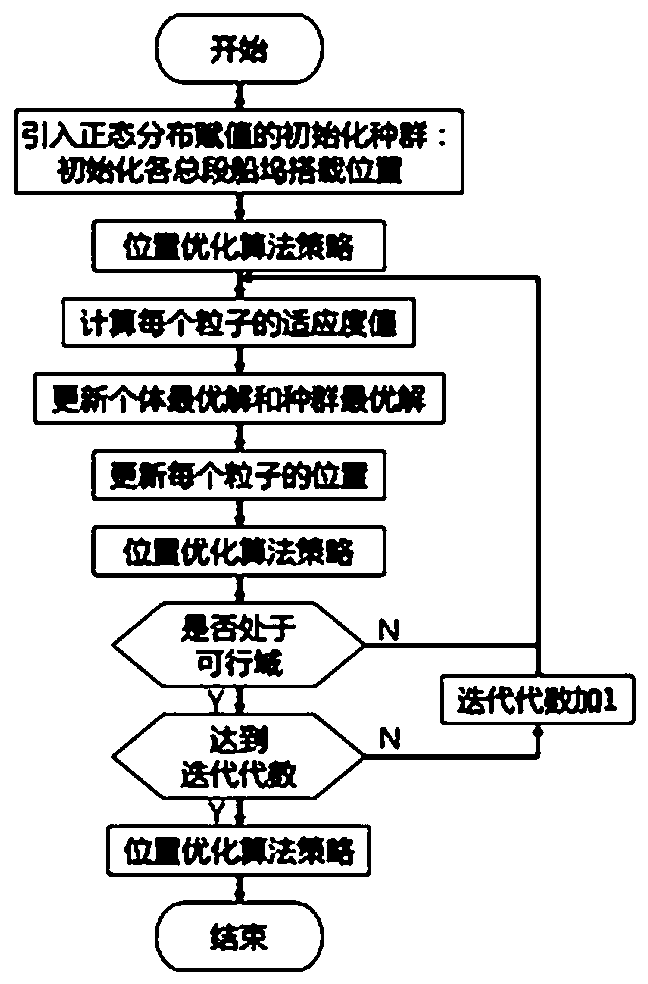

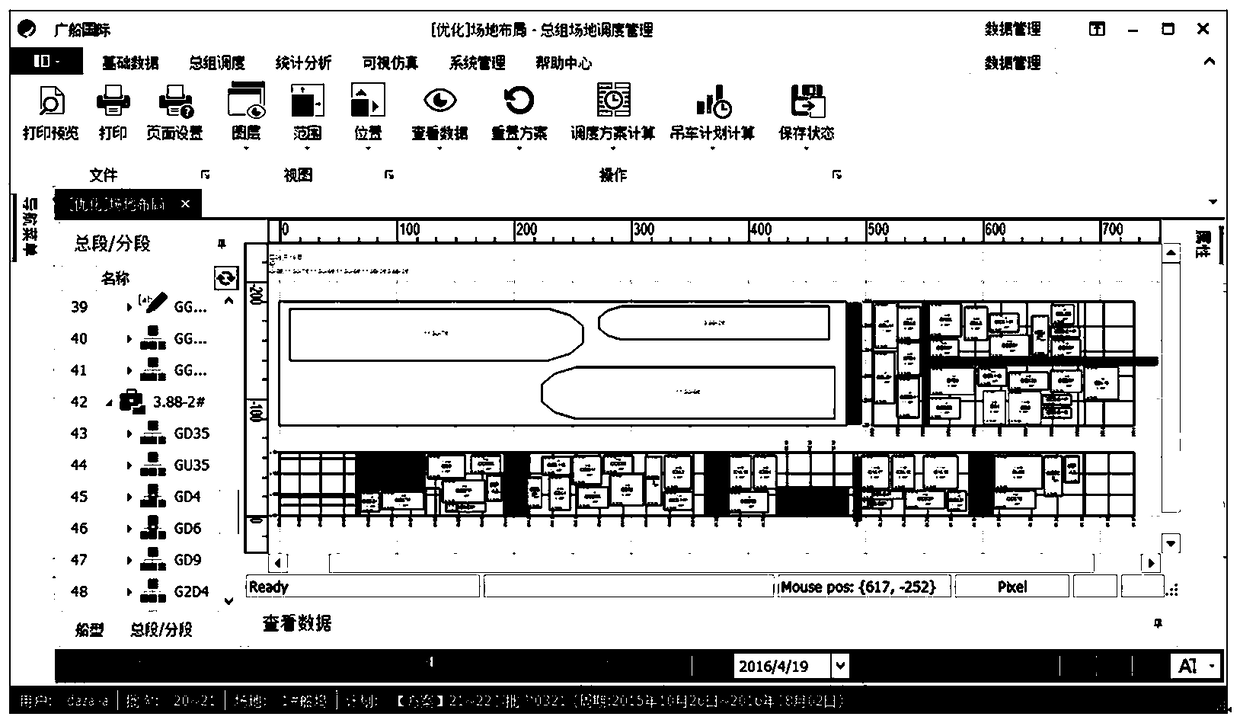

[0065] Example: such as Figure 1-6 As shown, the present invention provides an intelligent layout optimization algorithm for the general group site of the shipyard, the basic data model of the general group site, the constraint condition relationship, the intelligent optimization algorithm for the site layout and the intelligent optimization algorithm for the crane plan.

[0066] Now take a shipyard as an example to describe the technical solution:

[0067] Constraint condition relations are related scheduling constraints based on the site rules, logistics logic and process flow set in the process of carrying the general group, and the optimization calculation constraints are shown in Table 10:

[0068] Table 10 Optimization Computational Constraints

[0069]

[0070] Based on the basic data model and constraint relationship, the initial conditions of particle swarm calculation are set as shown in Table 11. image 3 It is the specific process of the particle swarm optimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com