High-efficiency needle mushroom harvesting and waste recycling system and method

A technology of waste recycling and Flammulina velutipes, which is applied in botany equipment and methods, mushroom cultivation, gardening, etc., can solve the problems of low degree of automation, bending of jet tubes under force, and low production efficiency, so as to improve cleaning effect and prevent folding The effect of bending damage and reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to clearly illustrate the technical features of this solution, the specific implementation of the present invention will be further described below according to the accompanying drawings.

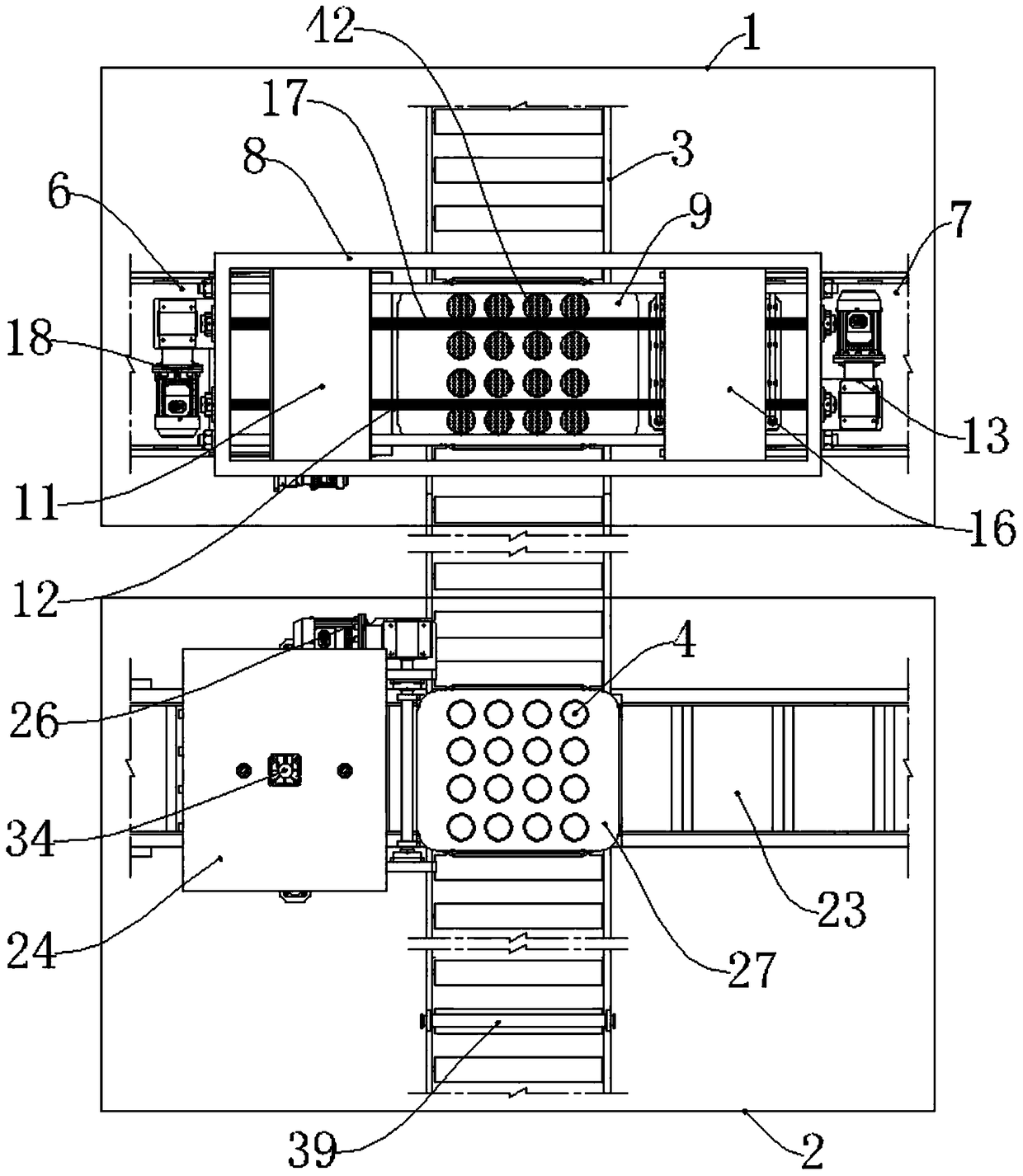

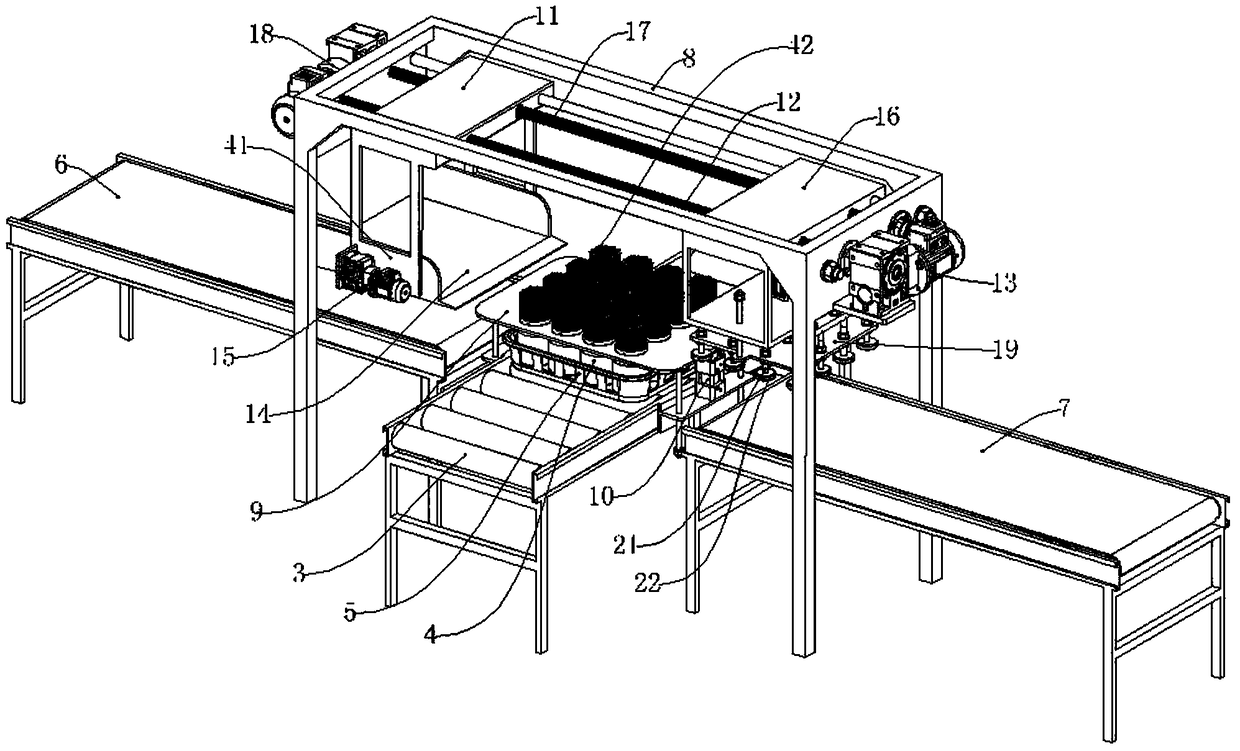

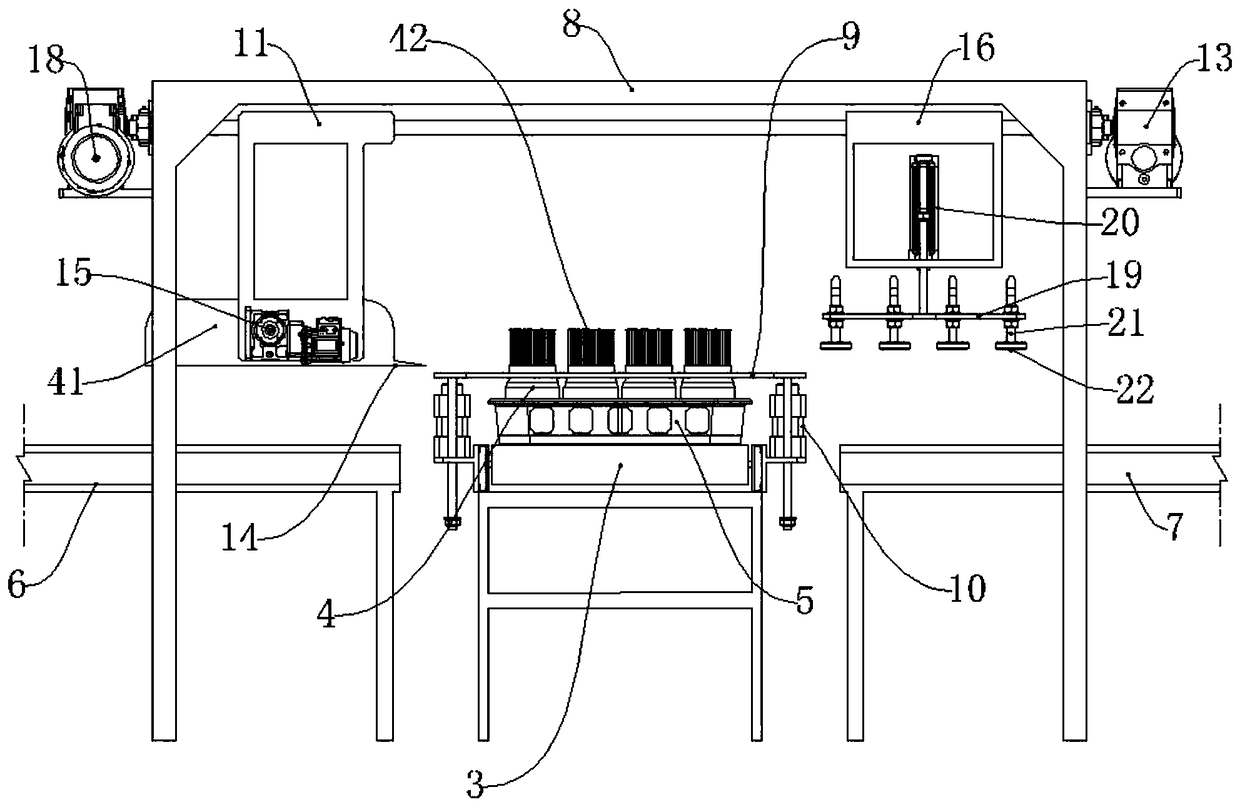

[0037] Figure 1 to Figure 12 Shown is the high-efficiency Flammulina velutipes harvesting-waste recycling system of the present invention, including a harvesting room 1, a recovery room 2 and a cultivation bottle group, the harvesting room 1 has higher requirements on the environment as a whole, and the harvesting room 1 is equipped with a collection of Flammulina velutipes. Device, recovery room 2 is relatively low to environmental requirement, is provided with waste recycling device in recycling room 2, and Flammulina velutipes harvesting device is connected with waste recycling device by cultivation bottle conveyor 3, and cultivation bottle conveyor 3 is a roller conveyor. The cultivation bottle group comprises a transfer basket 5 and sixteen cultivation bottles 4, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com