Automatic tea kneading machine and operation method thereof

A technology of tea kneading machine and driving machine, which is applied in the direction of tea processing before extraction, can solve problems such as immature technology, and achieve the effect of meeting the requirements of automatic production and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

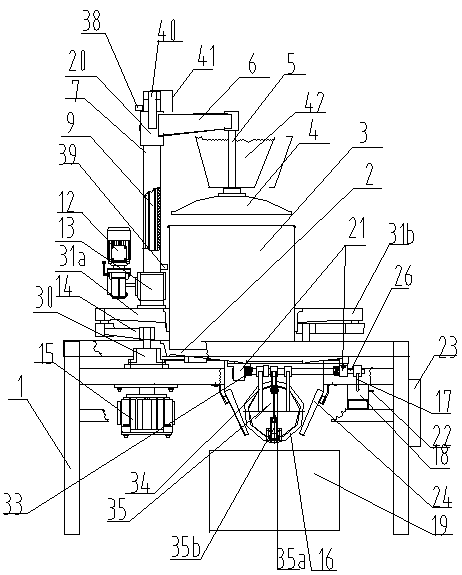

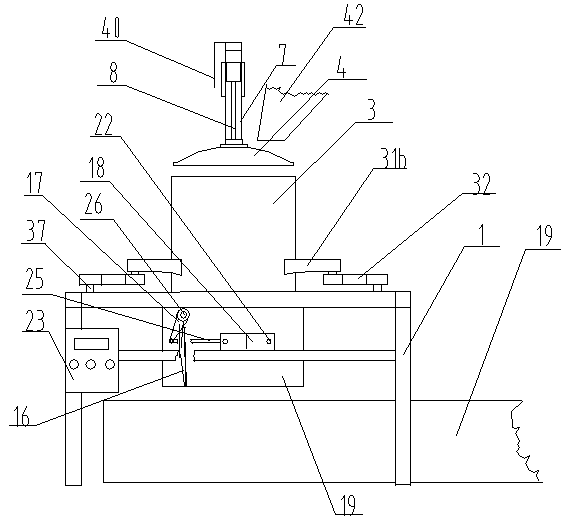

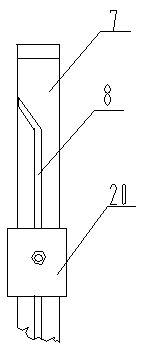

[0014] Embodiment 1: a kind of automatic tea kneading machine, comprises frame 1, is located at the controller 23 of frame 1, is located at the kneading platform 2 on the frame 1, is located at the kneading driving machine 15 below the frame 1, by The push arm 14 driven by the kneading drive machine 15, the kneading barrel 3 which is driven by the pushing arm, the lifting and transposition gland 4 and the gland handle 5 arranged in the kneading barrel 3, and the bottom cover at the bottom of the kneading table 16. The first fixed arm 31a of the kneading barrel 3 is provided with a lifting driver 12, and the lifting driver 12 is connected to the lifting screw 9 in the vertically arranged guide strut 7 through the transmission assembly 13, and the guide strut 7 side A guide groove 8 penetrating the column arm is provided, a sliding cylinder 20 is set on the guiding sliding column 7, a cantilever 6 is arranged on the sliding cylinder 20, the front end of the cantilever 6 is connec...

Embodiment approach 2

[0015] Embodiment 2: An operation method for an automatic tea kneading machine. The controller 23 is operated to start the lifting driver 12, which drives the lifting screw 9 in the sliding column 7 to rotate, and the rotation of the lifting screw 9 is driven by the lifting nut 10 and the connecting arm 11. The slider 20 first rises vertically along the guide groove 8 of the guide column 7, so that when the cantilever 6 lifts the gland 4 higher than the mouth edge of the kneading barrel 3, then pushes the slider 20 to the right along the guide groove 8 of the guide column 7 The deflection operation drives the gland 4 to deflect to the left. When the gland 4 leaves the kneading barrel 3 completely, the deflection limit sensor 40 sends a signal to the controller 23, and the controller 23 controls the lifting drive 12 to suspend work and controls the lower hopper 42 Unloading, after unloading, lift the driver 12 to start, drive the gland 4 to return to the kneading barrel 3, the c...

Embodiment 1

[0016] Embodiment 1: A kind of automatic tea kneading machine, is provided with frame 1, is provided with kneading table 2 on frame 1, is provided with kneading barrel 3 on kneading table 2, and kneading barrel 3 is evenly distributed with 3 fixed Arms, 1 first fixed arm 31a and 2 second fixed arms 31b, are provided with kneading driving machine 15 below the frame 1, and the driving shaft of kneading driving machine 15 passes through the bearing seat 30 and is located on the kneading table 2 to promote One end of the arm 14 is fixed, and the other end of the push arm 14 is hinged with a fixed arm 31 on the kneading bucket 3, and the other two fixed arms on the kneading bucket 3 are respectively connected with two driven arms on the kneading table 2. 32 one ends are hinged, and the other ends of the two driven arms 32 are hinged with two hinge posts 37 that are located on the rolling table 2. A gland 4 and a gland handle 5 that can be lifted and shifted are arranged in the knea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com