Goods sorting system and method

A sorting system and cargo technology, applied in the field of robots, can solve the problems of high construction cost of steel platform, large labor demand, and efficiency impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

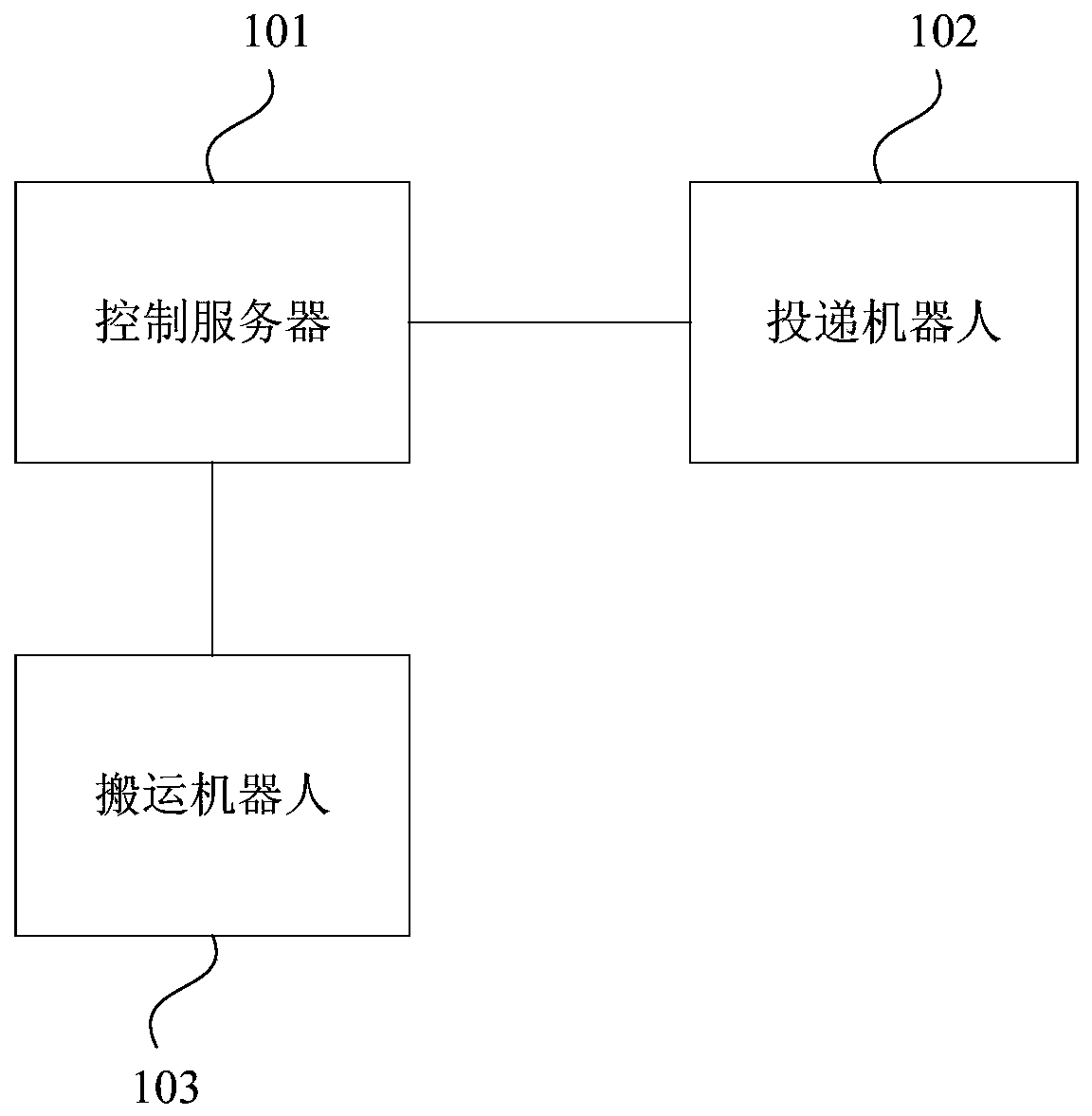

[0047] figure 1 It is a schematic structural diagram of the goods sorting system in Embodiment 1 of the present invention. This embodiment is applicable to the situation of sorting goods. The goods sorting system mainly includes the following parts: control server 101, delivery robot 102 and first handling robot 103.

[0048] In this embodiment, the control server 101 establishes communication connections with the delivery robot 102 and the handling robot 103 respectively, so as to realize the control and scheduling of the entire cargo sorting system. Further, the control server 101 refers to a software system with data storage and information processing capabilities, which can be connected with the delivery robot 102, the handling robot 103, and other hardware input systems or software systems in the system through wired or wireless. The control server 101 can issue tasks to the delivery robot 102 and the handling robot 103, deliver information to workers, collect statistics...

Embodiment 2

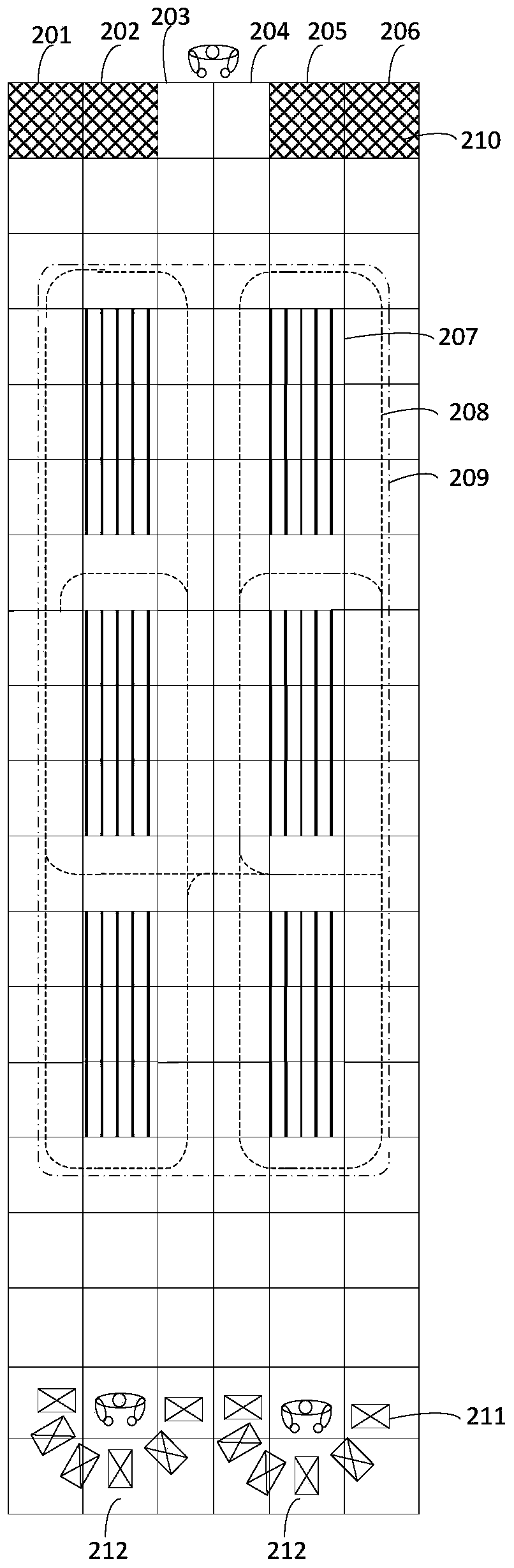

[0070] This embodiment further optimizes the cargo sorting system on the basis of the foregoing embodiments. Figure 2a It is a schematic layout diagram of a group of sorting systems in Embodiment 2 of the present invention.

[0071] In this embodiment, the cargo sorting system also includes a collection container group; the collection container group includes a plurality of collection container groups, one collection container group includes at least one collection container, and a plurality of collection container groups Distributed in the field in an array, the horizontal and vertical passages formed by the gaps in the array are the driving passages of the robot, and one cargo container corresponds to at least one road direction, and the opening of the cargo container is the delivery port of the goods.

[0072] Such as Figure 2aAs shown, the robot travels in at least one group of work areas, and each group of work areas includes a first column sub-area 201, a second colum...

Embodiment 3

[0092] This embodiment further optimizes the cargo sorting system on the basis of the foregoing embodiments. image 3 It is a structural schematic diagram of the delivery robot and the handling robot in the third embodiment of the present invention.

[0093] Such as image 3 As shown, the delivery robot is mainly composed of a delivery robot body 302 and a delivery mechanism 301 arranged on the delivery robot body, and the transport robot is mainly composed of a jacking device 303 and a transport robot body 304 . Further, a delivery mechanism 301 is set on the delivery robot, the height of the upper surface of the delivery mechanism 301 from the ground is greater than or equal to the height of the upper surface of the cargo container 305 from the ground, and a jacking device 303 is set on the handling robot, and the lifting type of the handling robot The height of the upper surface of the device 303 is less than the height of the lower surface of the container from the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com