Continuous Ceramic Grouting Molding Process

A grouting molding, continuous technology, applied in the direction of ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems that complex shapes or steps cannot be applied to the molding and manufacturing of hollow ceramic products, etc., and achieve low labor intensity and easy Continuous production, less trouble and labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

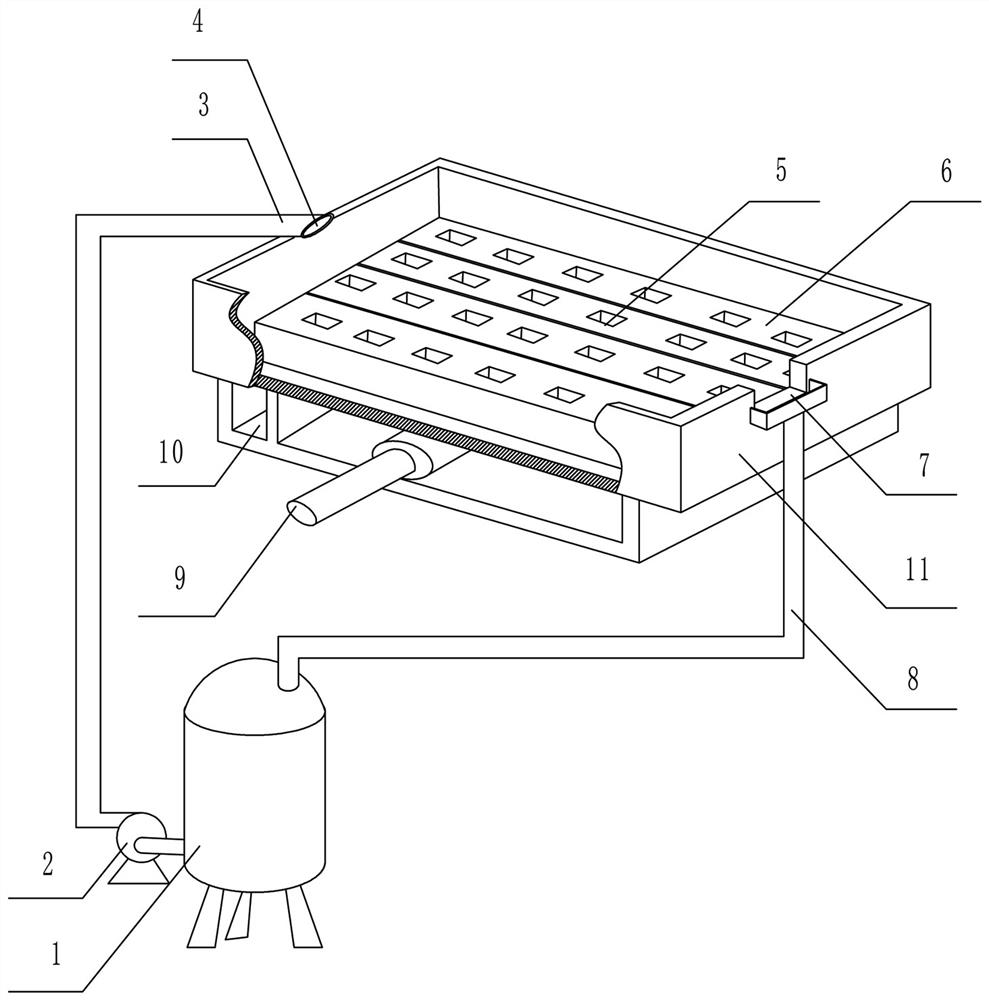

[0017] The present embodiment provides a continuous ceramic grouting molding process, comprising the following steps:

[0018] Ingredients: provide ceramic slurry;

[0019] Assembly: Provide a hollow ceramic slip-casting molding worktop and a mold with multiple molding cavities inside, arrange the molds densely in the hollow ceramic slip-casting molding worktop, An overflow port and a grouting port are respectively provided on the side wall of the grouting forming worktop;

[0020] Molding: casting the ceramic slurry through the grouting port into a plurality of the molding cavities and overflowing through the overflow port;

[0021] Demoulding: After the ceramic slurry in the molding cavity is solidified to the thickness of the hollow ceramic finished product, the ceramic slurry on the hollow ceramic grouting molding table is discharged, thereby forming ceramics in the molding cavity. A crude green body. The crude ceramic green body is dried and trimmed to obtain a finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com