Automatic conveying device for granular pesticide intermediates

An automatic conveying device and intermediate technology, applied in the field of automation, can solve the problems of high labor cost and low work efficiency, and achieve the effects of reducing the number of workers, simple structure and high space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

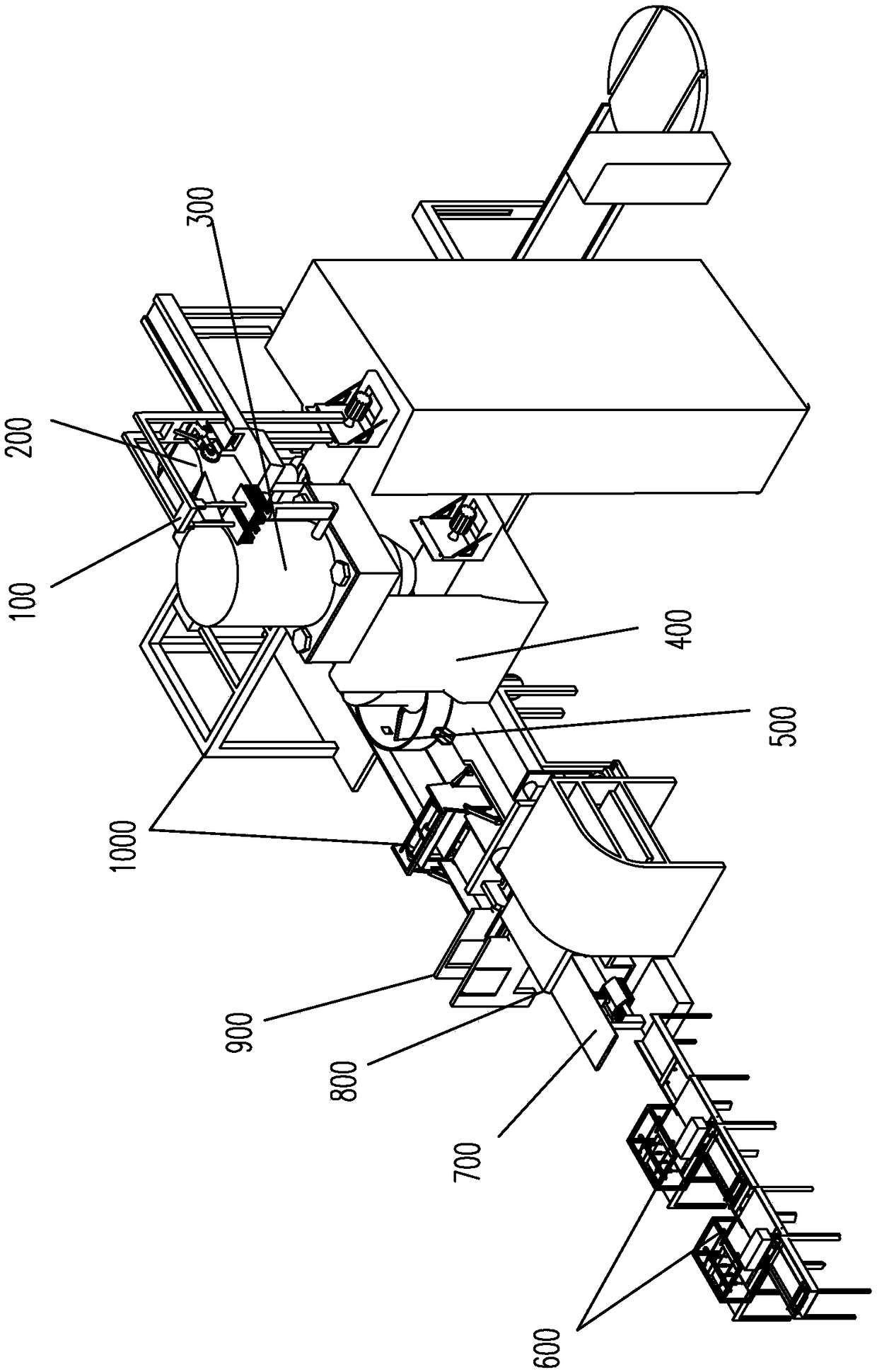

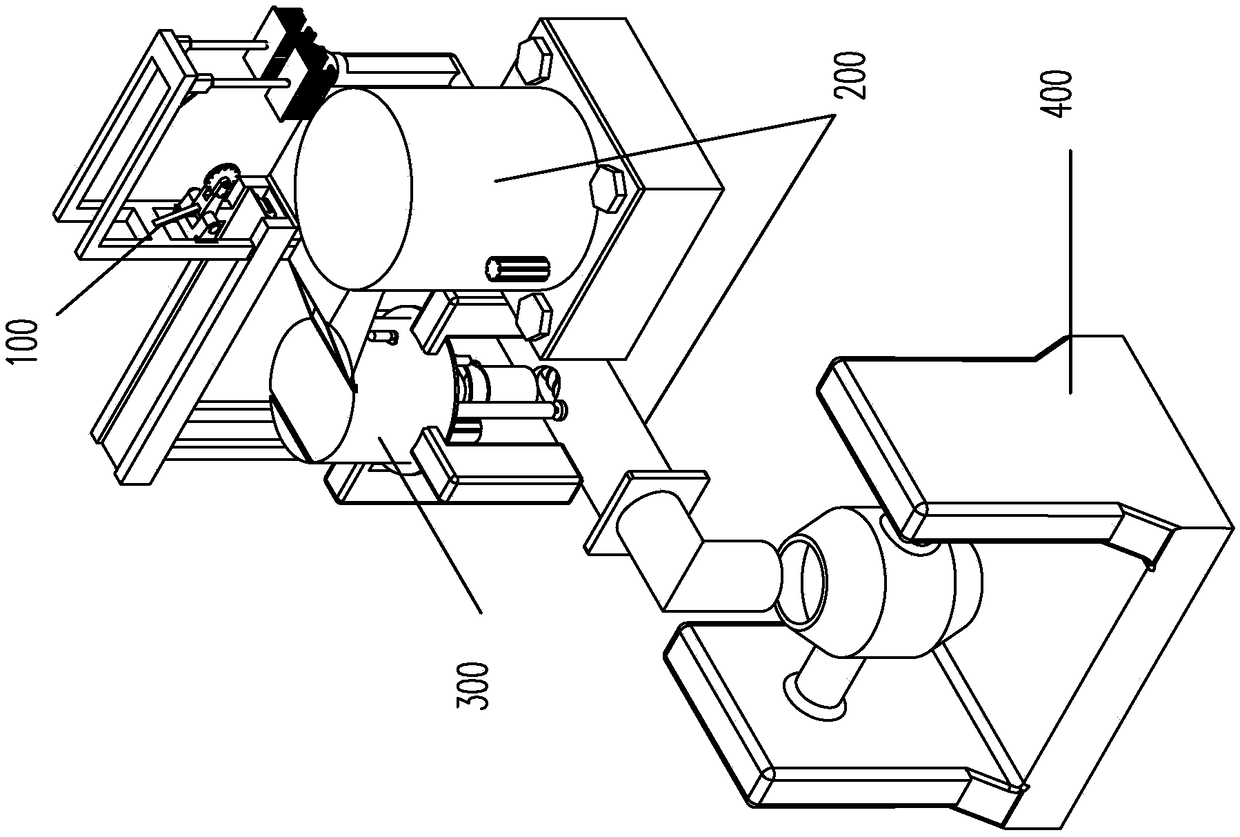

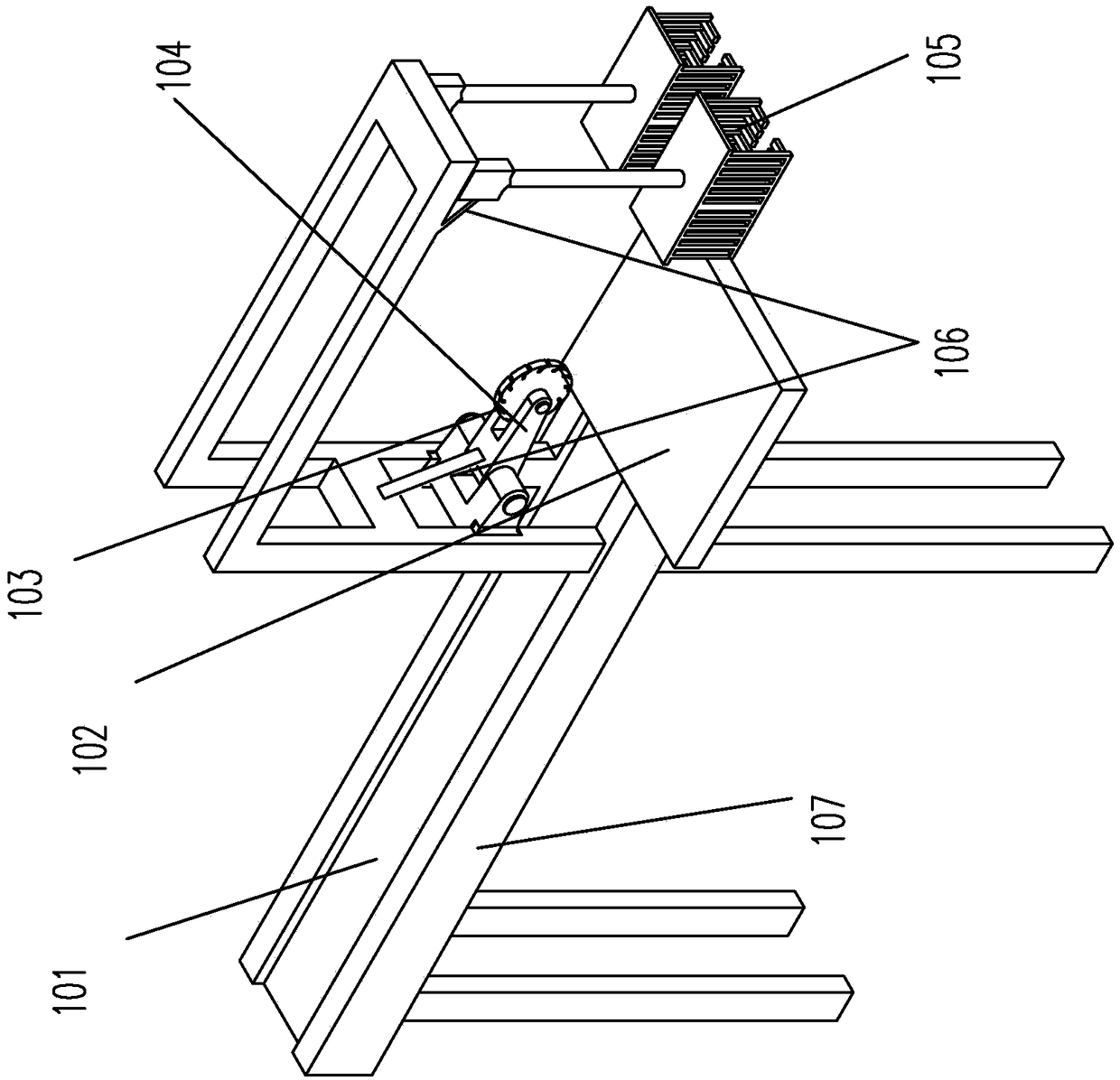

[0031] Such as Figure 1-2 As shown, a granular pesticide intermediate automatic delivery device, the granular pesticide intermediate automatic delivery device consists of a bag unpacking device 100, a reaction device 200, a material delivery device 300, a dryer 400, a sub-sieve filling device 500, a set of The bag device 600, the steering transfer machine 700, the bag opening device 800, the packaging device 900 and the stacking and packaging device 1000 are composed; the bag unpacking device 100 is arranged on a high platform, and the material conveying device 300 is arranged under the bag unpacking device 100. The device 200 is set under the discharge port of the material conveying device 300, the dryer 400 is set on the left side of the reaction device 300, the sub-sieving filling device 500 is set on the left side of the dryer 400, and the bagging device 600 is set on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com