High-performance flame-retardant abs resin and its preparation process

A technology of ABS resin and preparation process, which is applied in the field of high-performance flame-retardant ABS resin and its preparation, can solve problems such as loss of instruments or products, burnout of flame-retardant ABS resin, and inability to slow down the fire, so as to achieve the goal of slowing down the fire The effect of developing and reducing losses suffered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

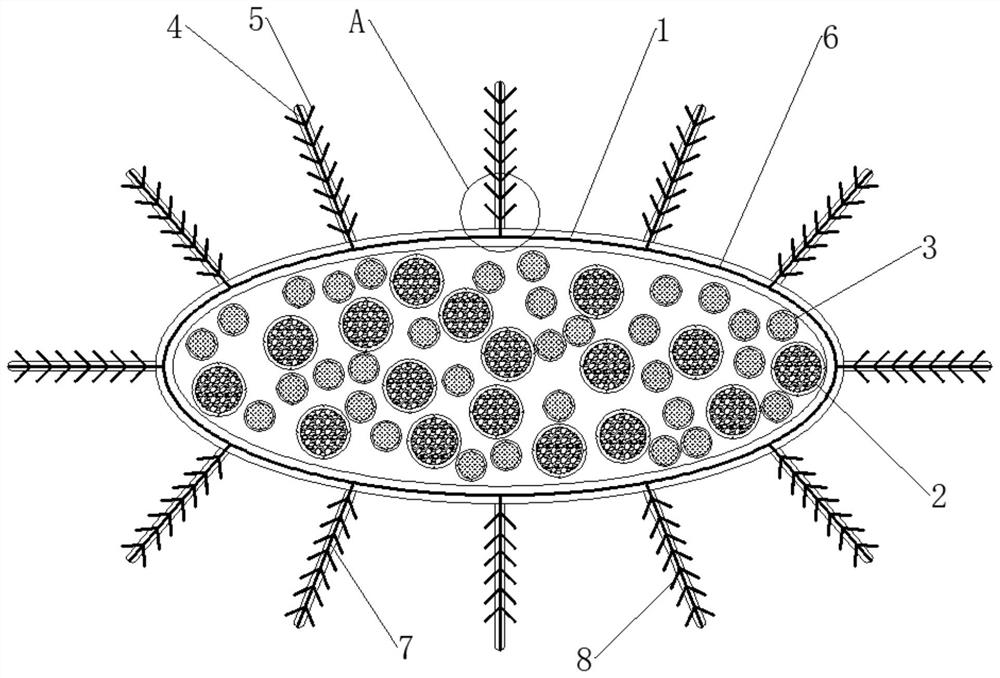

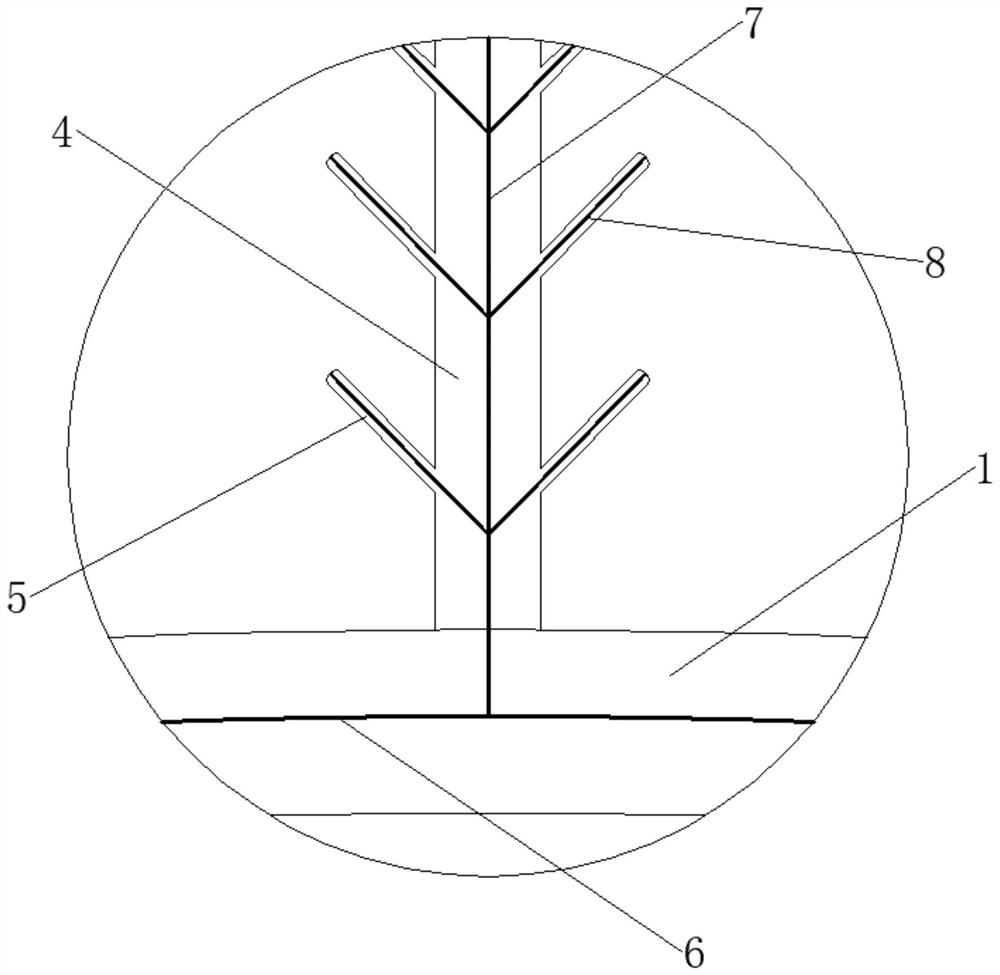

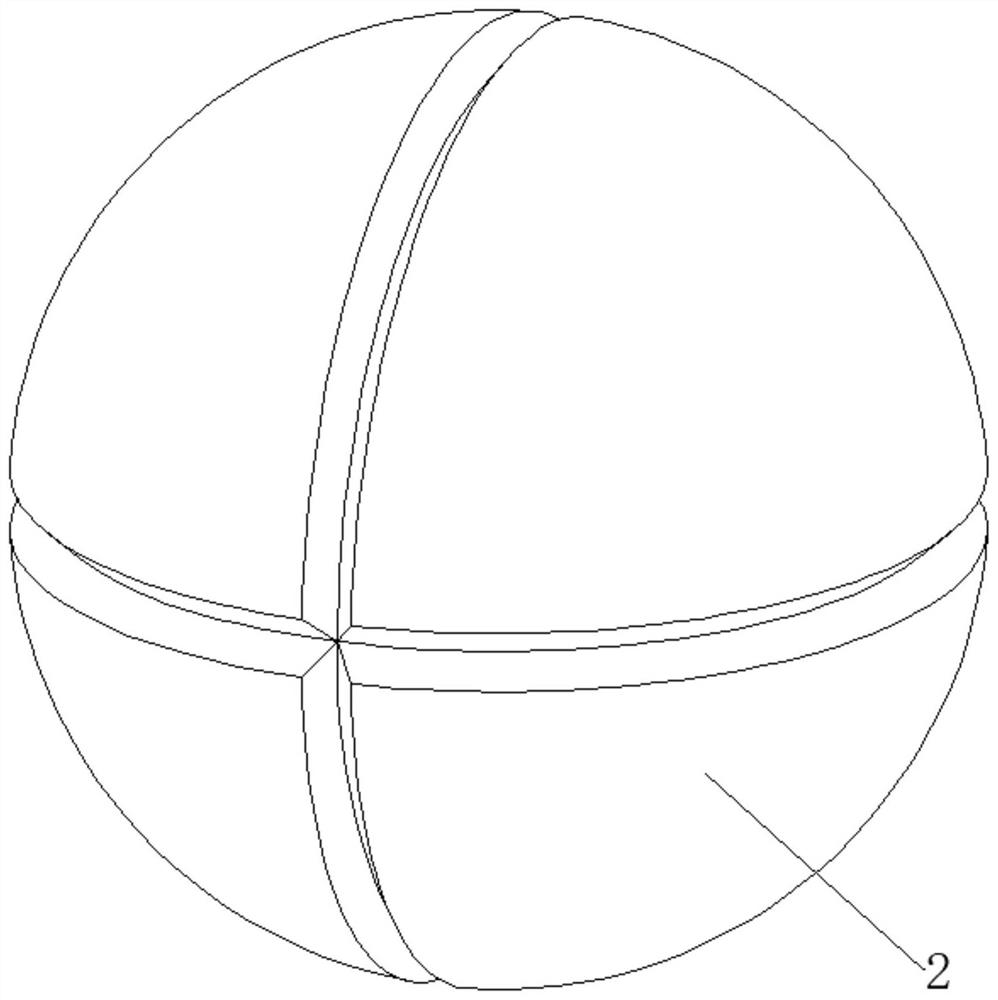

[0043] see Figure 1-5 , with high-performance flame-retardant ABS resin, including ABS resin raw materials and flame-retardant reinforcing balls, ABS resin raw materials include acrylonitrile (A), 1,3-butadiene (B) and styrene (S), of which the three The weight ratio is A:B:S=20:30:50, and flame retardants and additives are added according to the usage scenarios, wherein the flame retardants can be tetrabromobisphenol A, brominated triazine, brominated epoxy resin At least one of them, whose weight accounts for 15% of the total mass of the flame-retardant ABS resin, can enhance the flame retardancy of the present invention, the maximum diameter of the flame-retardant reinforcing ball is 2 mm, and the weight ratio of the flame-retardant reinforcing ball and the rest of the ABS resin raw materials The ratio is 1:8, the flame retardant reinforced ball includes a flame retardant reinforced ball shell 1, and the flame retardant reinforced ball shell 1 is wrapped with a plurality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com