Column type molten salt heat absorber device and starting method thereof

A heat absorber and heating device technology, applied to solar collectors, solar collector safety, solar collector controllers, etc., can solve problems such as the complicated start-up process of molten salt heat absorbers, and achieve safe start-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

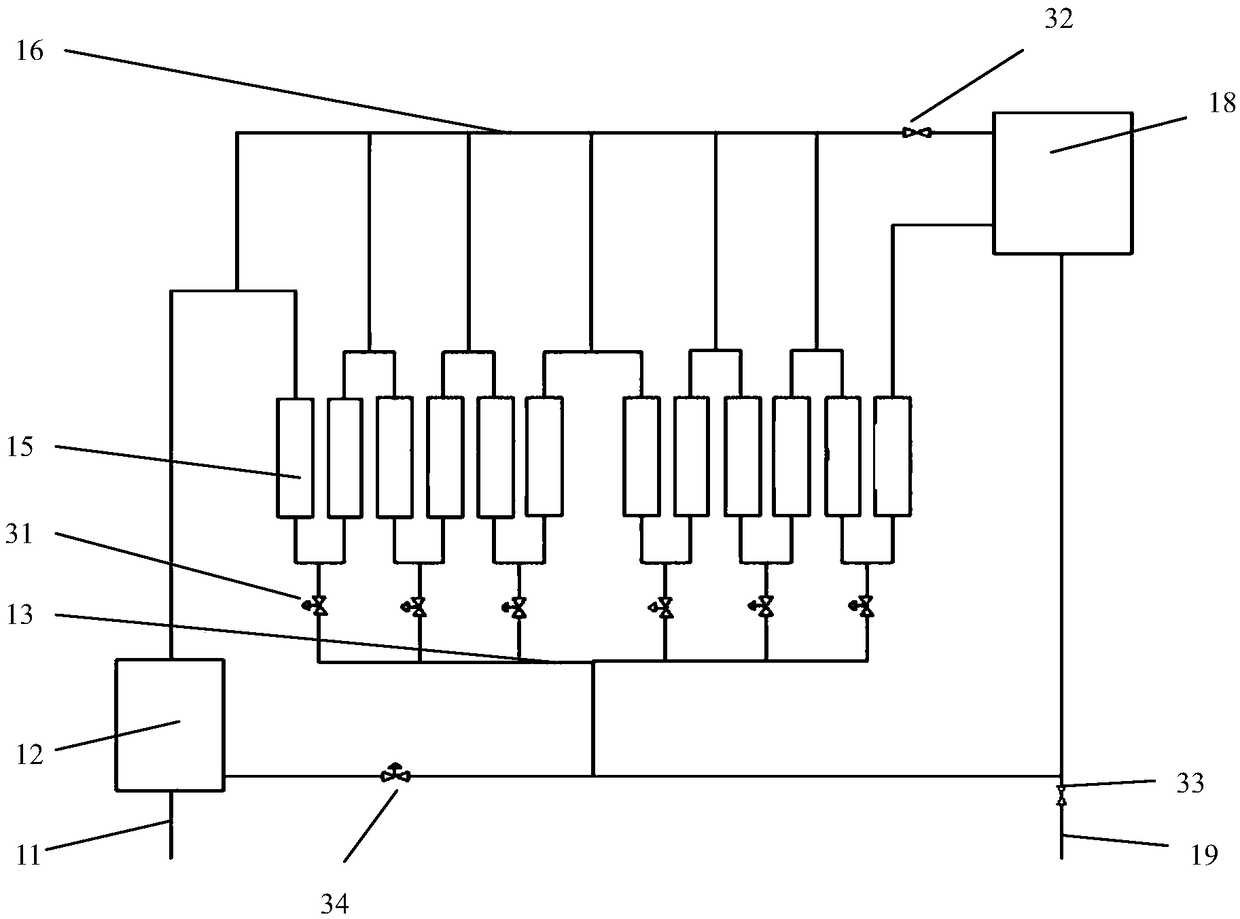

[0051] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 As shown, it also includes: a number of flowmeters, the inlet of the riser 11, the downcomer 19, the heat absorber unit 15 and the outlet of the heat absorber unit 15 are respectively provided with a flowmeter for obtaining the flow rate of the molten salt.

[0052] In a further embodiment of the present invention, a plurality of pressure gauges are provided at the inlet tank 12, the outlet tank 18 and the outlet of the heat absorber unit 15, respectively, for obtaining the pressure signal of the molten salt.

[0053] In a further embodiment of the present invention, it also includes: a salt trap valve 31 arranged at the lower header 13, an exhaust valve 32 arranged at the upper header 16, a downcomer throttle valve 33 arranged at the downcomer 19, And a bypass valve 34 arranged on the bypass.

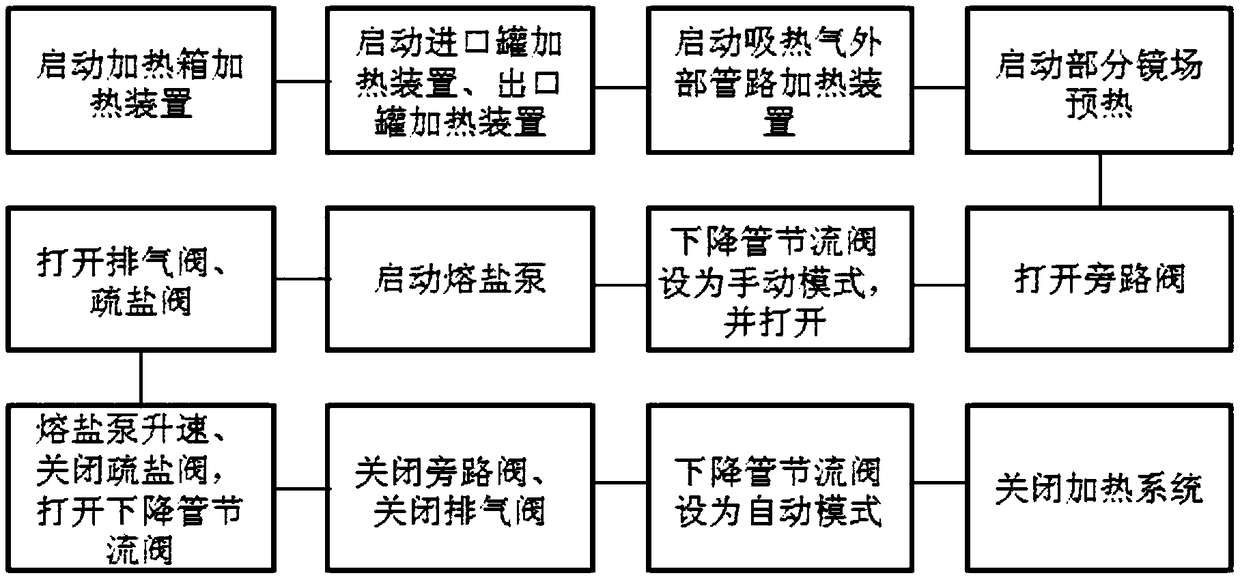

[0054] The starting method of the present invention is illustrated below:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com