Motion control method for workpiece table of lithography machine

A technology of motion control and workpiece table, applied in the direction of electric controllers, controllers with specific characteristics, etc., can solve the problems that affect the machining accuracy of feed motion trajectory and cannot eliminate the steady-state tracking error, so as to overcome the steady-state position tracking error, improving dynamic performance and positioning accuracy, and the effect of flexible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

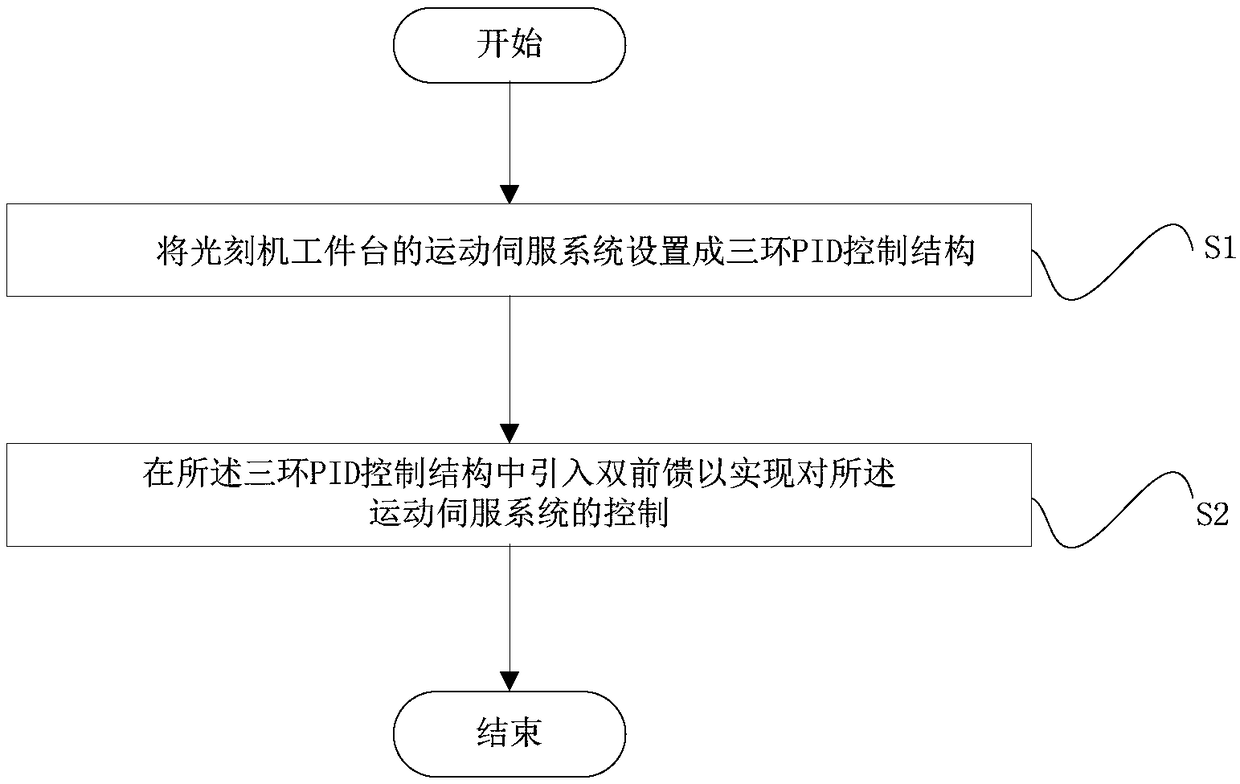

[0057] Such as figure 1 As shown, the present invention provides a method for controlling the motion of a lithography machine workpiece table, the method comprising the following steps:

[0058] (S1) Setting the motion servo system of the workpiece table of the lithography machine into a three-loop PID control structure;

[0059] (S2) Introducing double feedforward in the three-loop PID control structure to realize the control of the motion servo system.

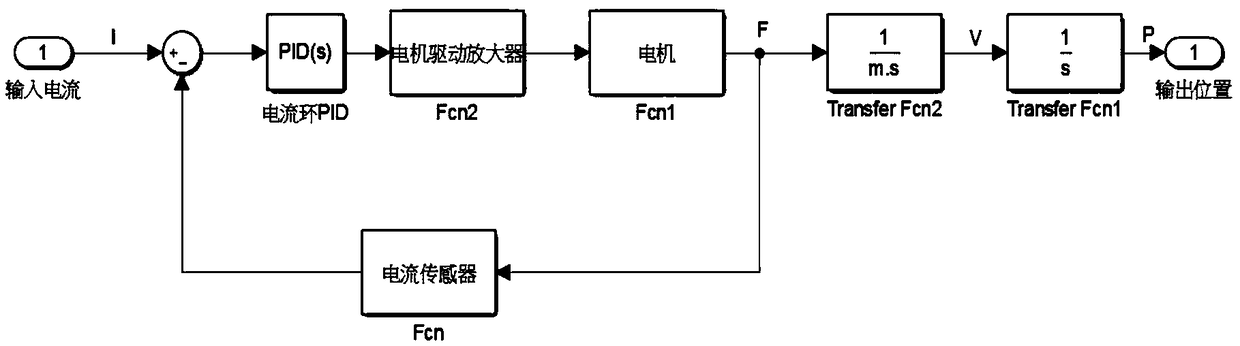

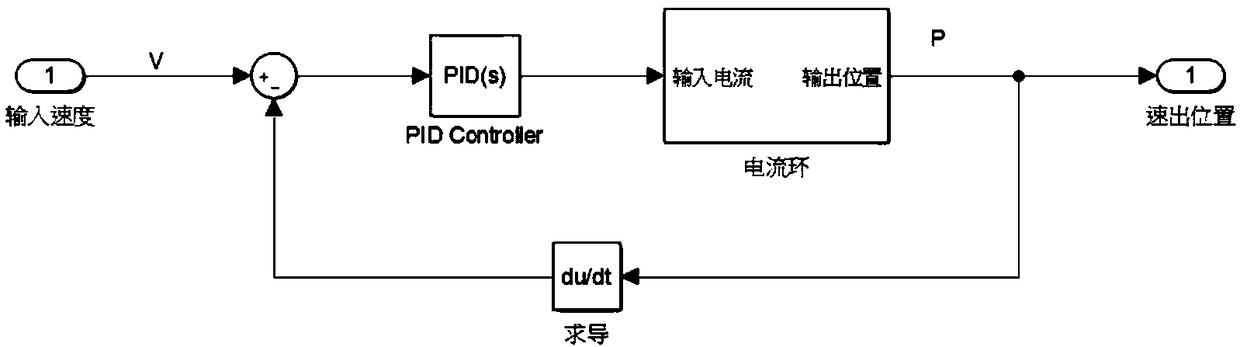

[0060] In this embodiment, the method adopts a double feedforward plus three-loop PID control structure, which is composed of current loop PID, speed loop PID, position loop PID, speed feedforward and acceleration feedforward, wherein the current loop PID , used to adjust the deviation response of the speed and position of the motion servo system; the speed loop PID is used to perform PID control on the speed deviation of the current loop PID; the position loop PID is used to control the current loop PID PID control of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com