Lithium battery with high safety structure

A safety structure, lithium battery technology, applied in the direction of batteries, battery electrodes, secondary batteries, etc., can solve the core problems of reaction heat transfer and accumulation, increase the risk of thermal runaway of lithium batteries, etc., to achieve extended heat Out-of-control time, safety improvement, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

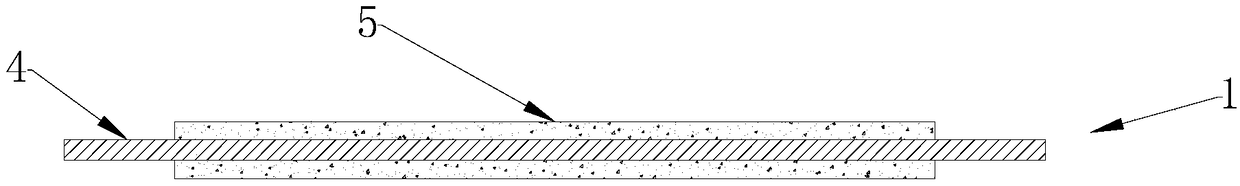

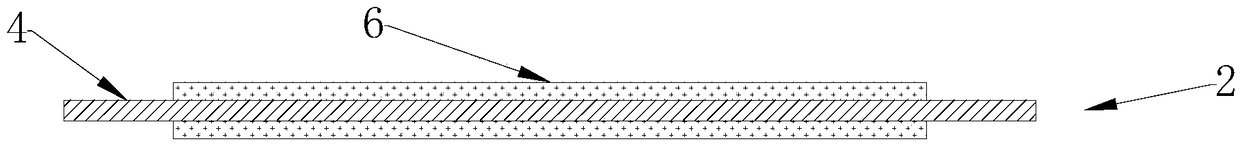

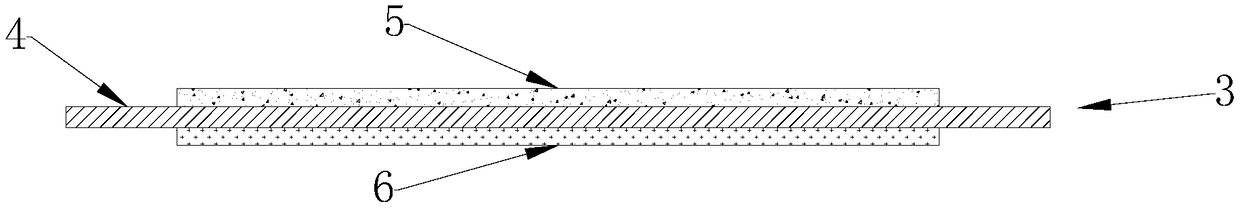

[0061] A positive pole piece of a lithium battery with a high safety structure, including an A-type electrode and a B-type electrode; both sides of the A-type electrode are coated with high-energy electrode materials, and both sides of the B-type electrode are coated with Clothed with high safety electrode material.

[0062] The high-energy electrode material is made of the following raw materials: high gram capacity positive electrode material LiNi 0.8 co 0.1 mn 0.1 o 2 94.00kg, PVDF 2.00k kg, carbon black 3.00kg, NMP 35kg.

[0063] The high-safety electrode material is made of the following raw materials: high-safety positive electrode material LiFePO 4 94.00kg, PVDF 2.00k kg, carbon black 3.00kg, NMP 35kg.

[0064] The preparation method of the positive pole sheet of the lithium battery with high safety structure comprises the following steps:

[0065] (1) Preparation of high-energy electrode materials: Stir PVDF and 25kg NMP evenly until PVDF is completely dissolved...

Embodiment 2

[0076] The lamination method of the high-safety lithium battery includes the following steps: for every two A-type electrodes used continuously, one B-type electrode is used for continuous lamination.

[0077] The positive pole piece and its preparation method, the negative pole piece and its preparation method, the electrolyte solution and its preparation method and the preparation method of the lithium battery of the high safety structure lithium battery are all the same as in Example 1.

Embodiment 3

[0079] The lamination method of the lithium battery with high safety structure includes the following steps: for every 4 A-type electrodes used continuously, one C electrode is used for continuous lamination.

[0080] The positive pole piece and its preparation method, the negative pole piece and its preparation method, the electrolyte solution and its preparation method and the preparation method of the lithium battery of the high safety structure lithium battery are all the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com