Automatic function testing equipment

A technology for functional testing and equipment, applied in the monitoring of photovoltaic systems, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of easy collisions during the movement of solar panels, lower detection qualification rates, and uncertain detection sites, etc., to avoid transportation. , the effect of increasing versatility and reducing input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

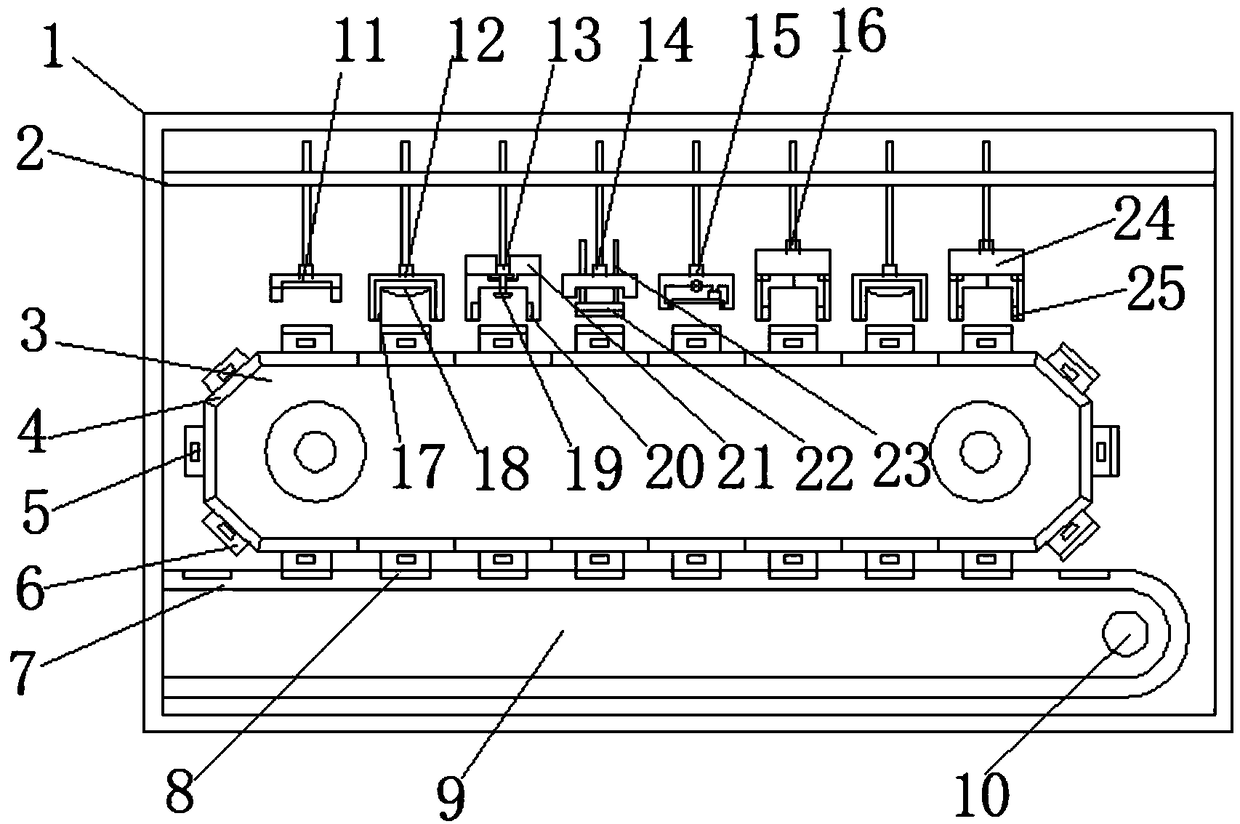

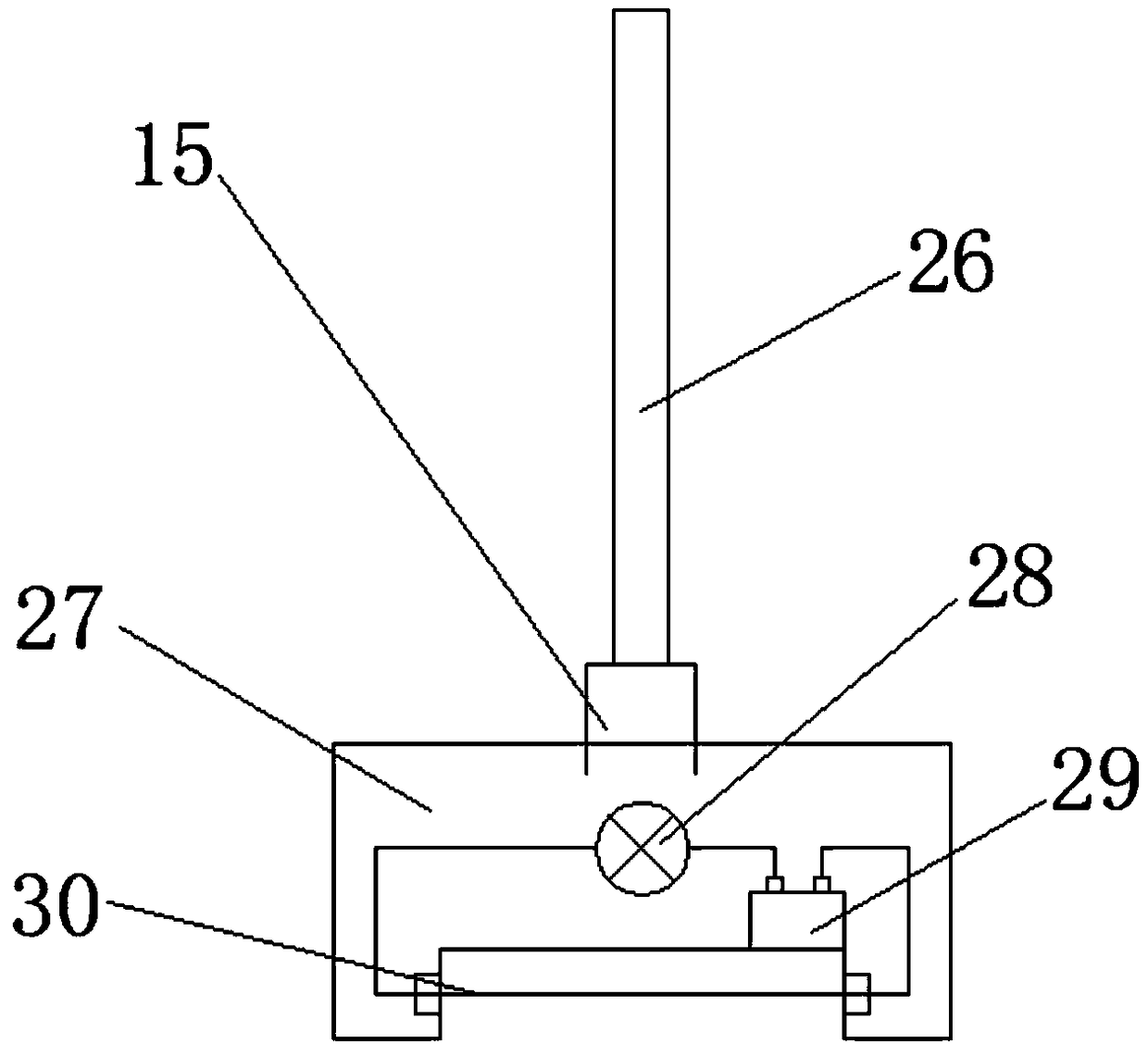

[0021] see figure 1 -2, the present invention provides a kind of technical scheme:

[0022] An automated function testing device, comprising a test chamber 1, a fixed rod 2, a processing belt 3, a shoe 4, a voltmeter 5, a placement table 6, a crawler belt 7, a placement groove 8, a conveyor belt 9, and a rotating shaft 10. The test equipment comprises a test chamber 1, a mover 11, a voltage tester 12, a waterproof tester 13, a press tester 14, an insulation measuring device 15, a sufficient discharger 16, a processing belt 3 and a transport belt 9. The test chamber 1 There is a cavity inside, and the test room 1 is convenient to create an environment without light, so as to avoid the influence of external natural light on the test. A fixed rod 2 is provided on the upper end of the cavity, and the fixed rod 2 is used for the use of various testing equipment. The two ends of the rod 2 are fixedly connected to the inner walls on both sides of the test chamber 1. The fixed rod 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com