Method for integrating and mounting satellite-borne TR assembly arrays with high heat flux density

A technology with high heat flux density and installation method, which is applied to antenna arrays, antenna array manufacturing devices, electrical components, etc., can solve the problems of high integration, inability to meet aerospace high-density heat dissipation requirements, large heat generation, etc., to overcome volume The effect of restriction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

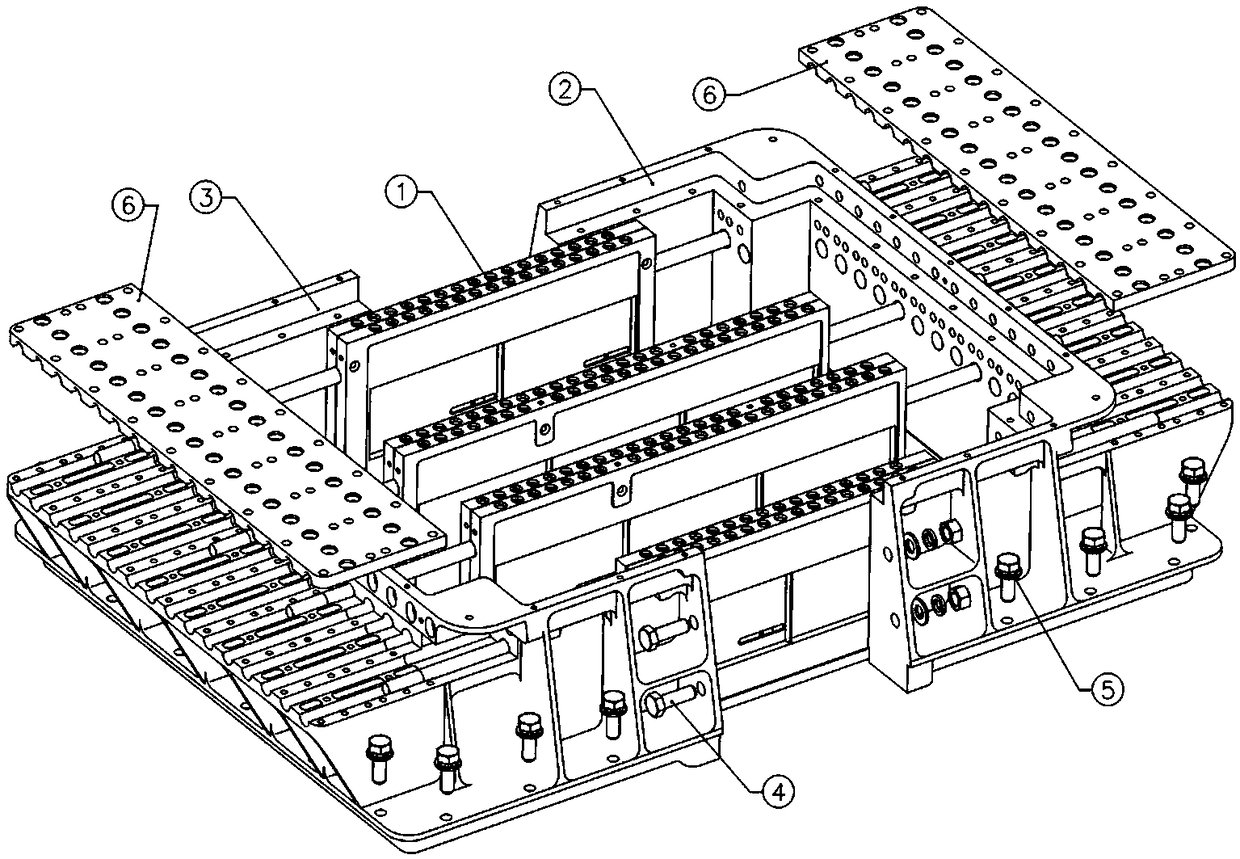

[0016] An integrated installation method for a spaceborne high heat flux TR component array, specifically including the following process:

[0017] Installation of stand-alone TR component module 1:

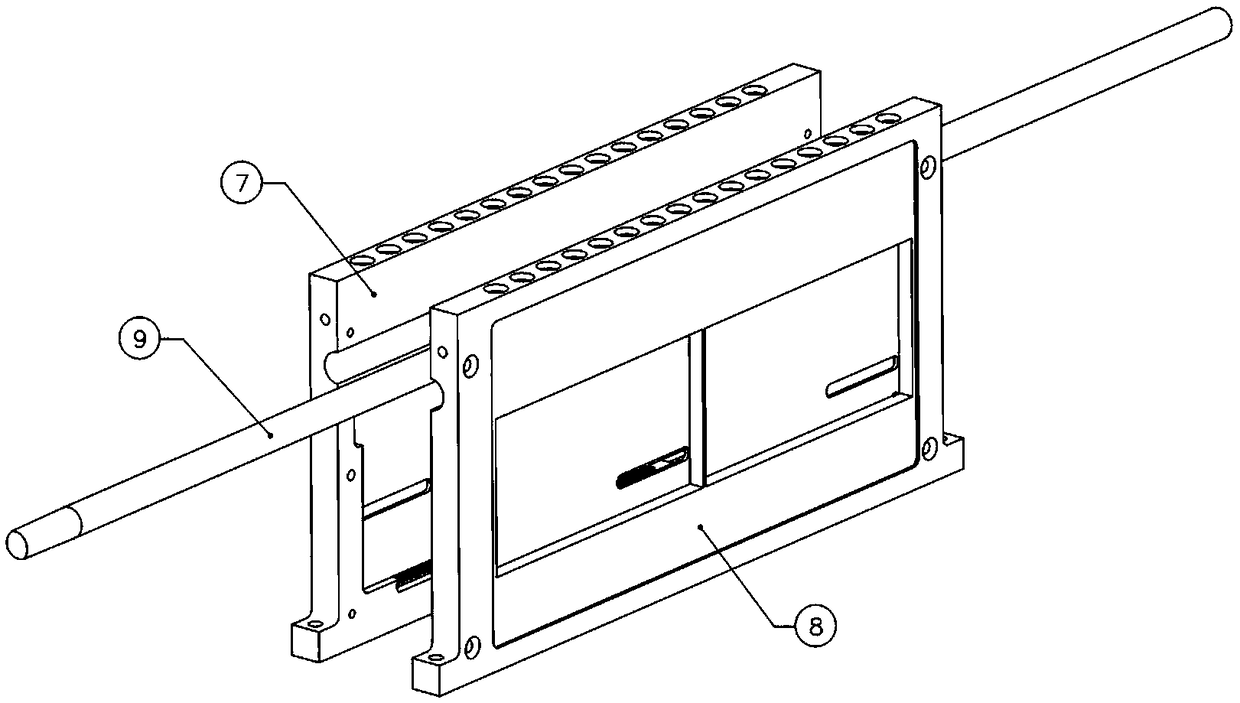

[0018] Step 1, such as figure 1 As shown, a heat pipe with high speed and uniform temperature conduction is sandwiched between two TR components, and both ends of the heat pipe are led out of the TR component to form an independent TR component module 1;

[0019] Preferably, the specific process of step 1 is as follows: the two TR components are the first TR component 7 and the second TR component 8 respectively, and a through-hole is set under the heating chips of the first TR component 7 and the second TR component 8. Semi-circular groove; the position of the groove depends on the number and position of high heat flux chips in the actual circuit.

[0020] Mounting ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com