Method for prolonging shelf life of hulless barley fresh wet noodles

A shelf life and highland barley technology, which is applied in the field of storage and preservation of fresh noodle products, can solve the problems of irritation and bad flavor, and achieve the effects of prolonging the shelf life, avoiding bad pungent smell, and uniform sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

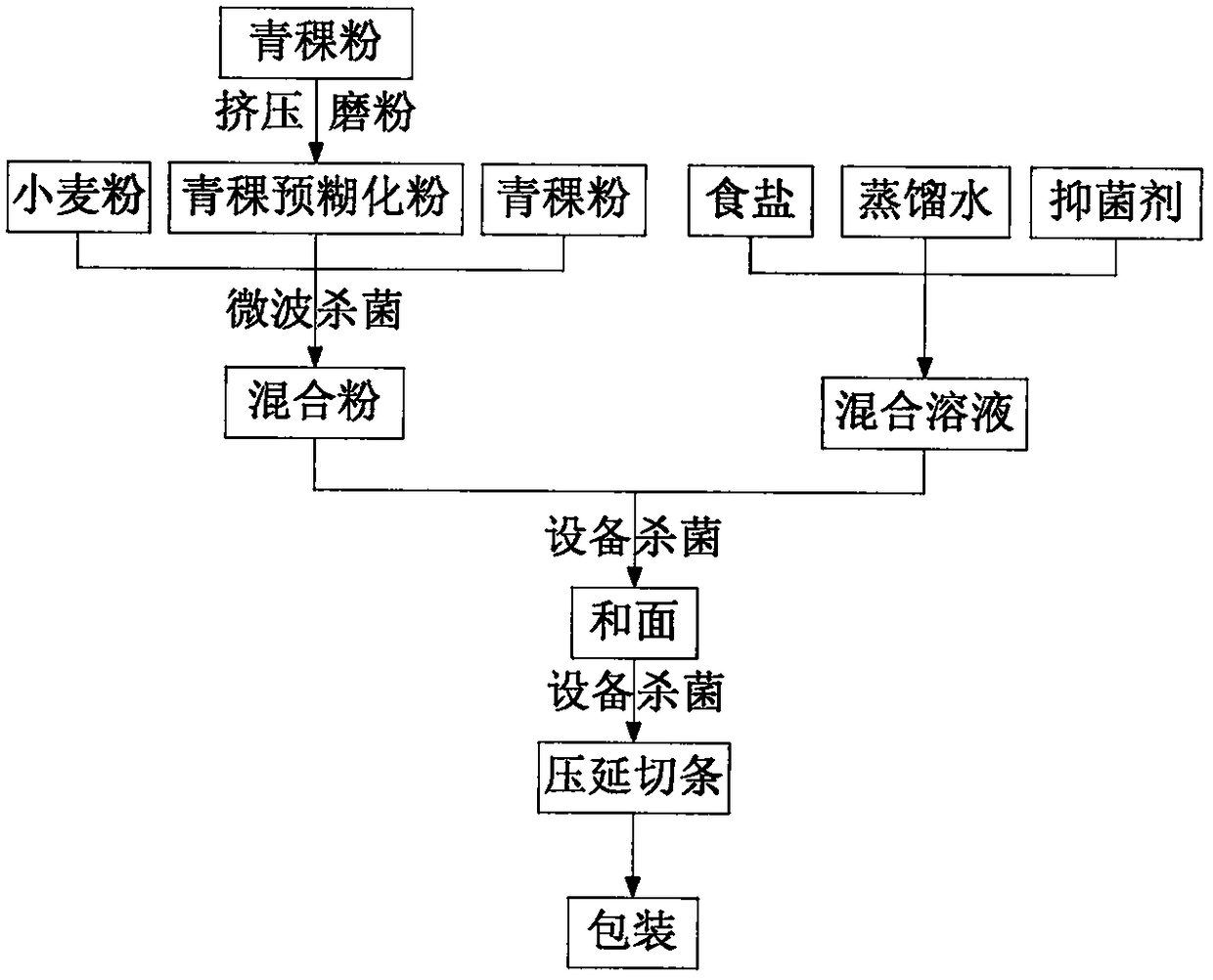

Method used

Image

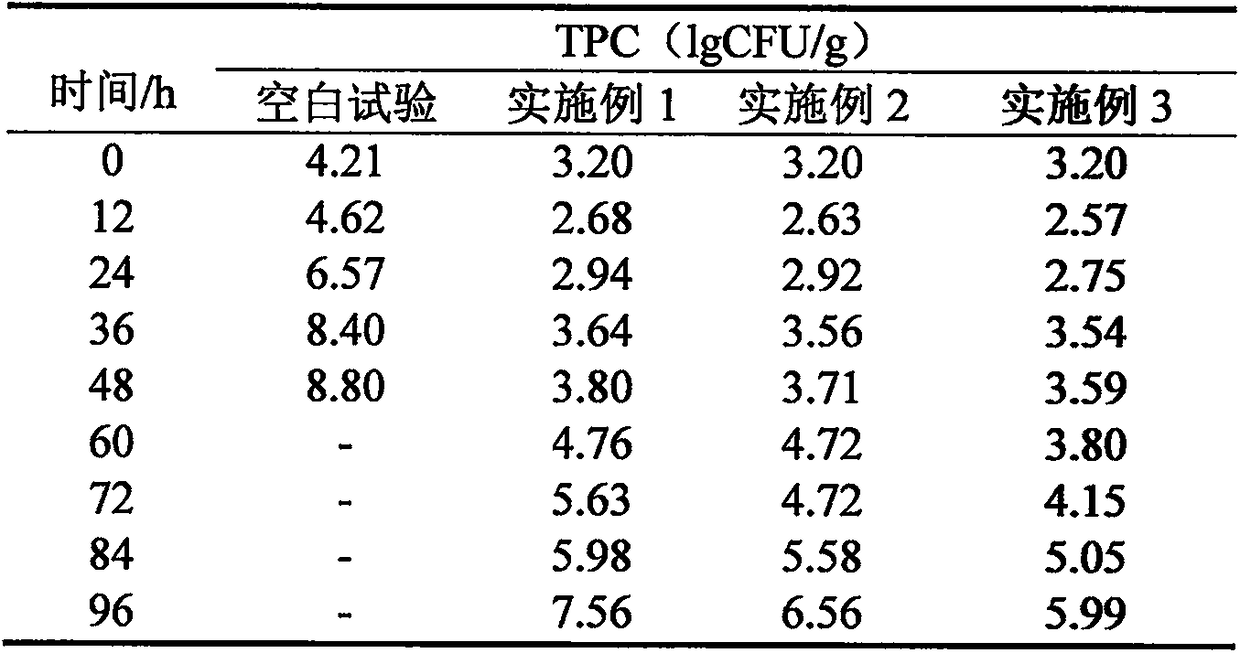

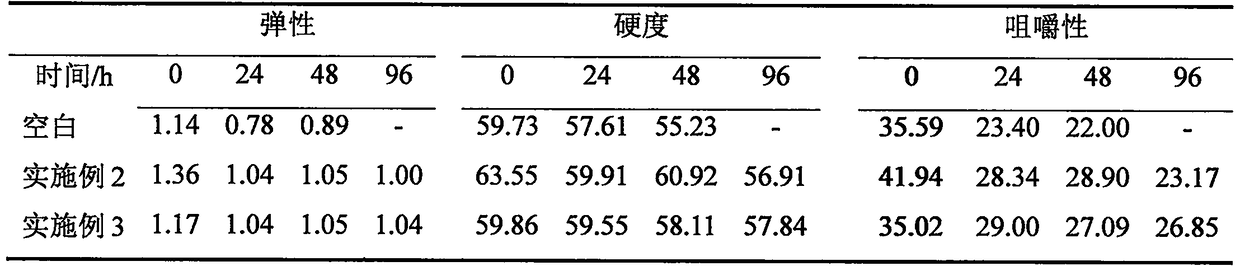

Examples

Embodiment 1

[0026] (1) Preparation of highland barley pregelatinized powder: pour the highland barley powder into the mixer, add appropriate amount of water and fully stir, adjust the moisture content of the highland barley powder to 16%, and then pour the uniformly mixed highland barley powder into the twin-screw extruder Extrusion and puffing are carried out in the screw feeding trough. The operating parameters of the twin-screw extruder are: the temperatures of the first zone to the fourth zone are 60°C, 90°C, 130°C and 160°C, the screw speed is 260r / min, the die hole The size is 0.39cm; after that, after the extruded puffed product is cooled and dried, it is pulverized and passed through a 60-mesh sieve to obtain the highland barley pregelatinized powder;

[0027] (2) Preparation of mixed powder: in parts by weight, 50 parts of highland barley pregelatinized powder and 50 parts of highland barley powder are mixed to obtain compound powder, then 40 parts of compound powder are fully mix...

Embodiment 2

[0035] (1) Preparation of highland barley pregelatinized powder: pour highland barley powder into a mixer, add appropriate amount of water and fully stir evenly, adjust the moisture content of highland barley powder to 16%, and then pour the mixed highland barley powder into a twin-screw extruder Extrusion and puffing are carried out in the screw feeding trough. The operating parameters of the twin-screw extruder are: the temperatures of the first zone to the fourth zone are 60°C, 90°C, 130°C and 160°C, the screw speed is 260r / min, the die hole The size is 0.39cm; after that, after the extruded puffed product is cooled and dried, it is pulverized and passed through a 60-mesh sieve to obtain the highland barley pregelatinized powder;

[0036] (2) Preparation of mixed powder: in parts by weight, 50 parts of highland barley pregelatinized powder and 50 parts of highland barley powder are mixed to obtain compound powder, then 40 parts of compound powder are fully mixed with 60 part...

Embodiment 3

[0044] (1) Preparation of highland barley pregelatinized powder: pour highland barley powder into a mixer, add appropriate amount of water and fully stir evenly, adjust the moisture content of highland barley powder to 16%, and then pour the mixed highland barley powder into a twin-screw extruder Extrusion and puffing are carried out in the screw feeding trough. The operating parameters of the twin-screw extruder are: the temperatures of the first zone to the fourth zone are 60°C, 90°C, 130°C and 160°C, the screw speed is 260r / min, the die hole The size is 0.39cm; after that, after the extruded puffed product is cooled and dried, it is pulverized and passed through a 60-mesh sieve to obtain the highland barley pregelatinized powder.

[0045] (2) Preparation of mixed powder: in parts by weight, 50 parts of highland barley pregelatinized powder and 50 parts of highland barley powder are mixed to obtain compound powder, and then 40 parts of compound powder are fully mixed with 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com