Non-woven fabric motion position correcting equipment for preparing paper diapers

A technology of moving position and non-woven fabrics, which is applied in the field of sanitary products, can solve the problems of position deviation, wrinkles in deviation correction, troublesome non-woven deviation correction, etc., and achieve the effect of ingenious structure, flexible movement and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

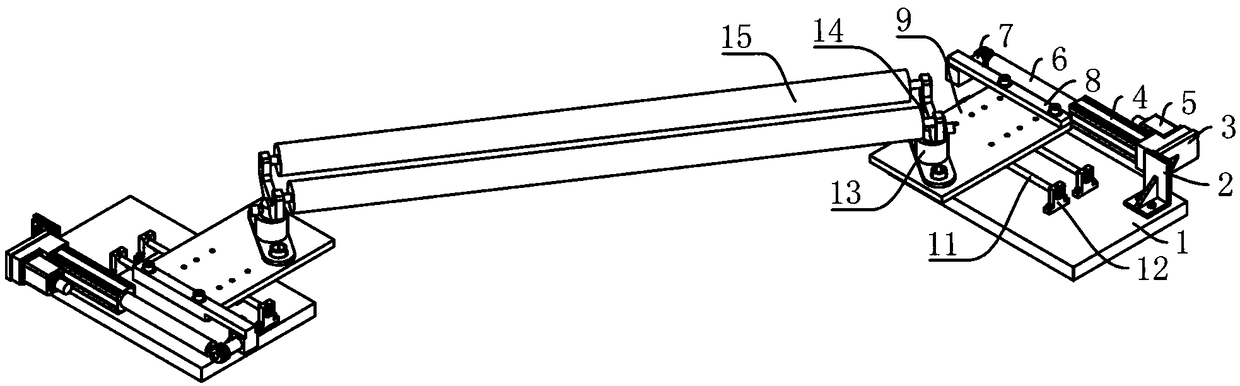

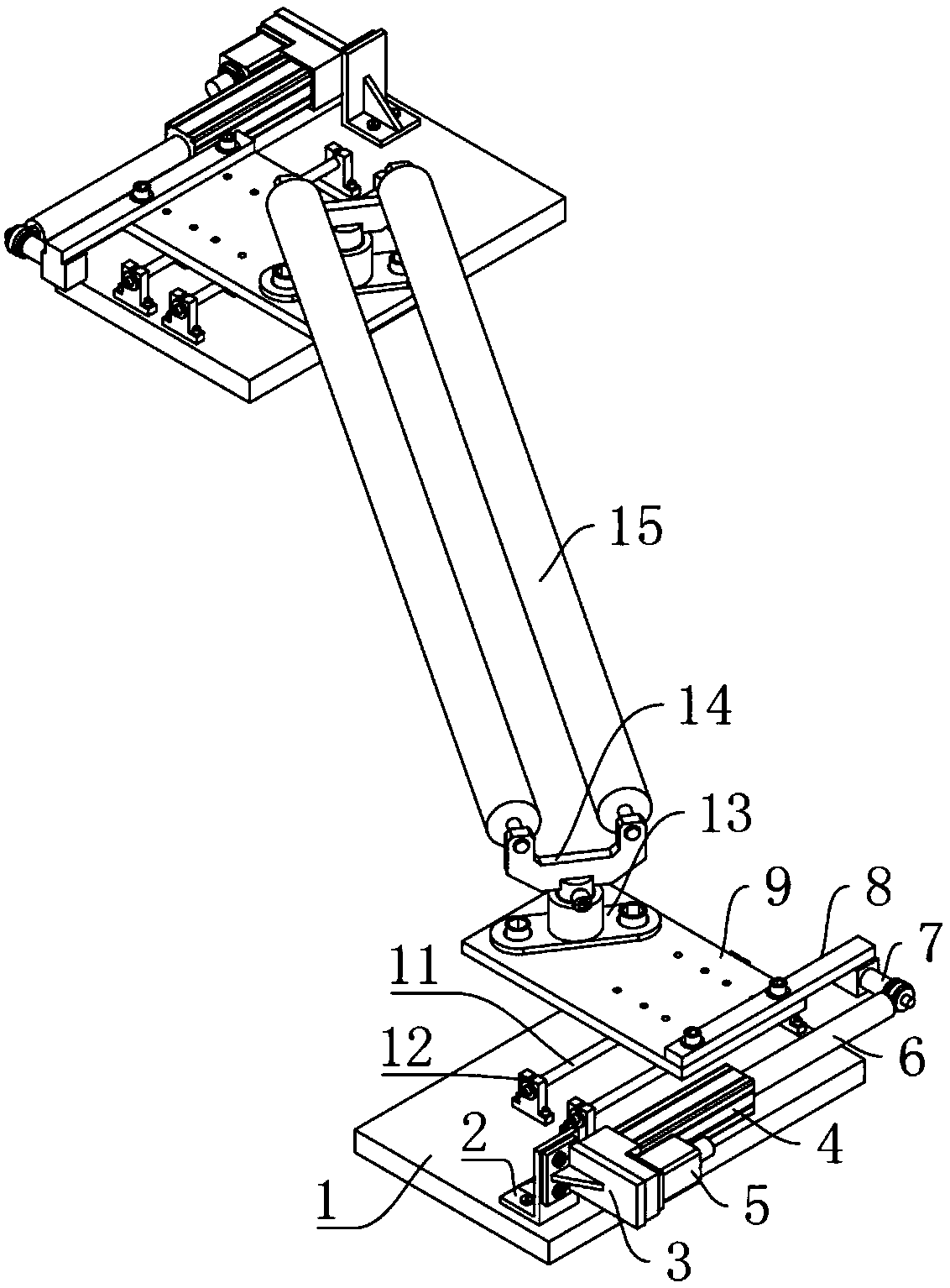

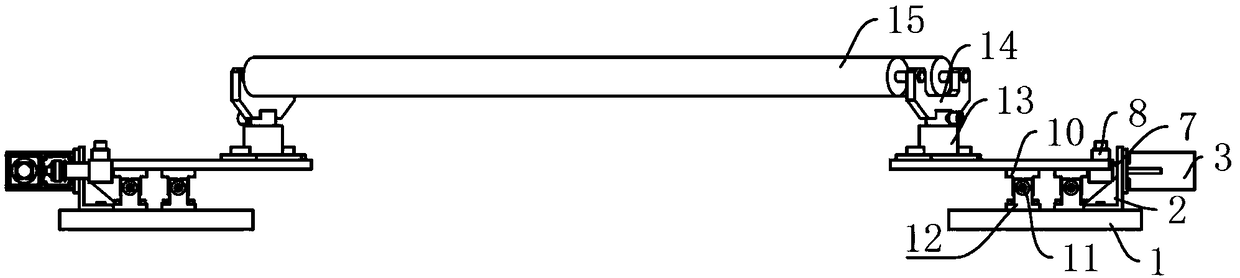

[0015] Such as Figure 1 to Figure 3 as shown, figure 1 It is a schematic diagram of the overall structure in the axial direction of a non-woven fabric movement position correction device for preparing diapers according to the present invention, figure 2 It is a schematic diagram of the overall structure in the direction of the other axial side of a non-woven fabric movement position correction device for preparing diapers according to the present invention, image 3 It is a schematic diagram of the overall structure in the front view direction of a non-woven fabric movement position correction device for preparing diapers according to the present invention. exist Figure 1 to Figure 3 In the illustrated embodiment, a non-woven fabric motion position correction device for preparing diapers includes a frame 1, a bracket 2, a cylinder mounting seat 3, a servo cylinder 4, a servo motor 5, a cylinder shaft 6, a connecting shaft 7, Connecting block 8, bearing seat mounting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com