Ceramic nanofiber hollow filter rod

A nanofiber and filter rod technology, which is applied in the field of ceramic nanofiber hollow filter rods, can solve the problems of low filter function, extremely high workshop requirements, and large material restrictions, so as to improve the molding efficiency, molding effect and filtration effect. Prominent, good hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

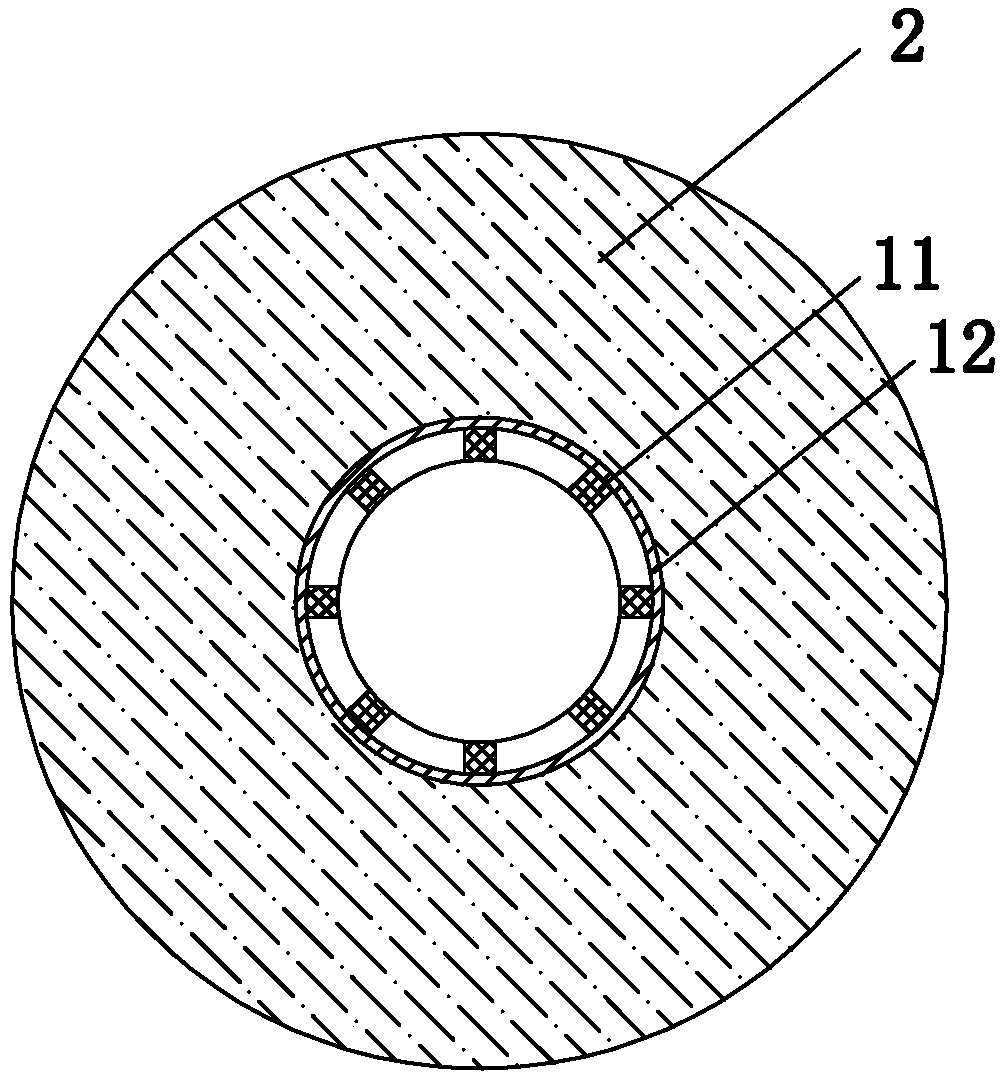

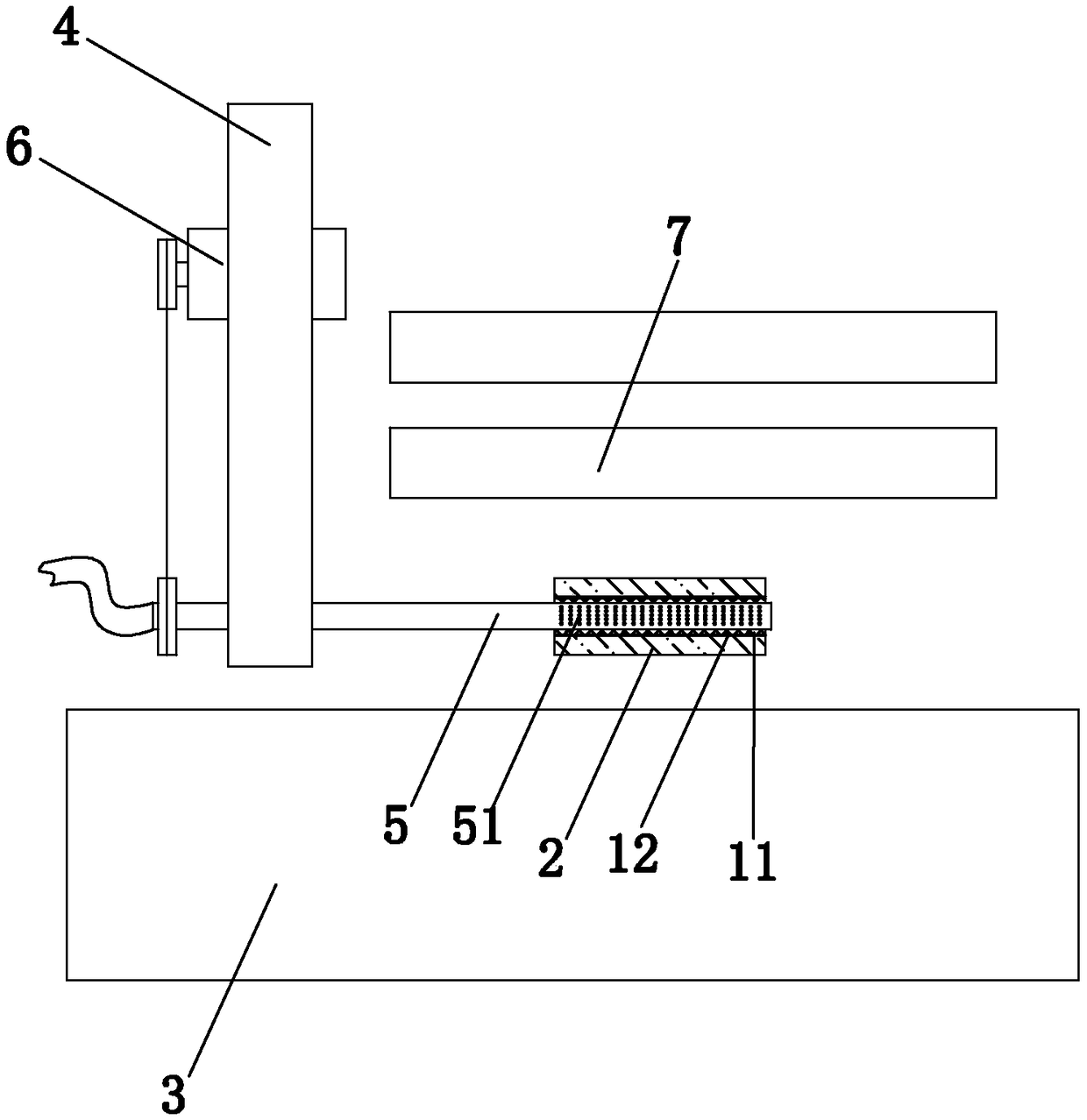

[0019] figure 1 As shown, the present embodiment provides a ceramic fiber hollow filter rod, which includes a support skeleton tube and a filter material layer 2 sleeved outside the support skeleton tube. The support skeleton tube includes a skeleton tube 11 and is sleeved outside the skeleton tube 11 The non-woven fabric 12; the filter material layer 2 is composed of the following materials in parts by weight: 65 parts by weight of short aluminum fibers, 20 parts by weight of nanofibers, 15 parts by weight of diatomaceous earth, and 10 parts by weight of adhesive. The particle size of the diatomite is 100 mesh to 250 mesh. The binder is an inorganic binder.

[0020] The adhesive can be acrylic glue. The non-woven fabric is PET non-woven fabric. The skeleton tube is made of PP material, and a plurality of penetrating holes are arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com