Multi-hammer ultrafine pulverizer

An ultra-fine pulverizer and pulverizer technology, which is applied in grain processing and other directions, can solve the problems of difficult pulverization of coarse fiber materials, serious wear and tear of accessories, and high cost of accessories, and achieve the effect of optimizing the pulverizing path, increasing the service life, and stabilizing the operation of the large plate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

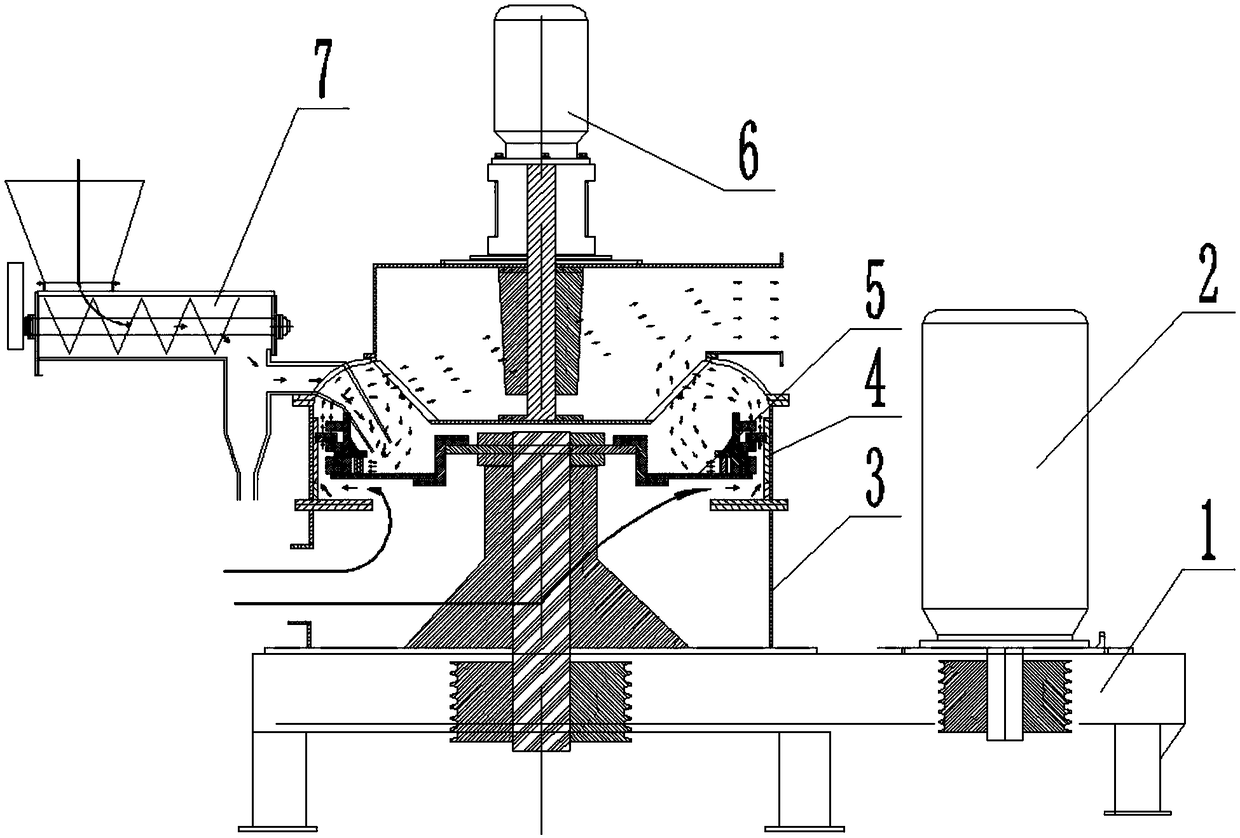

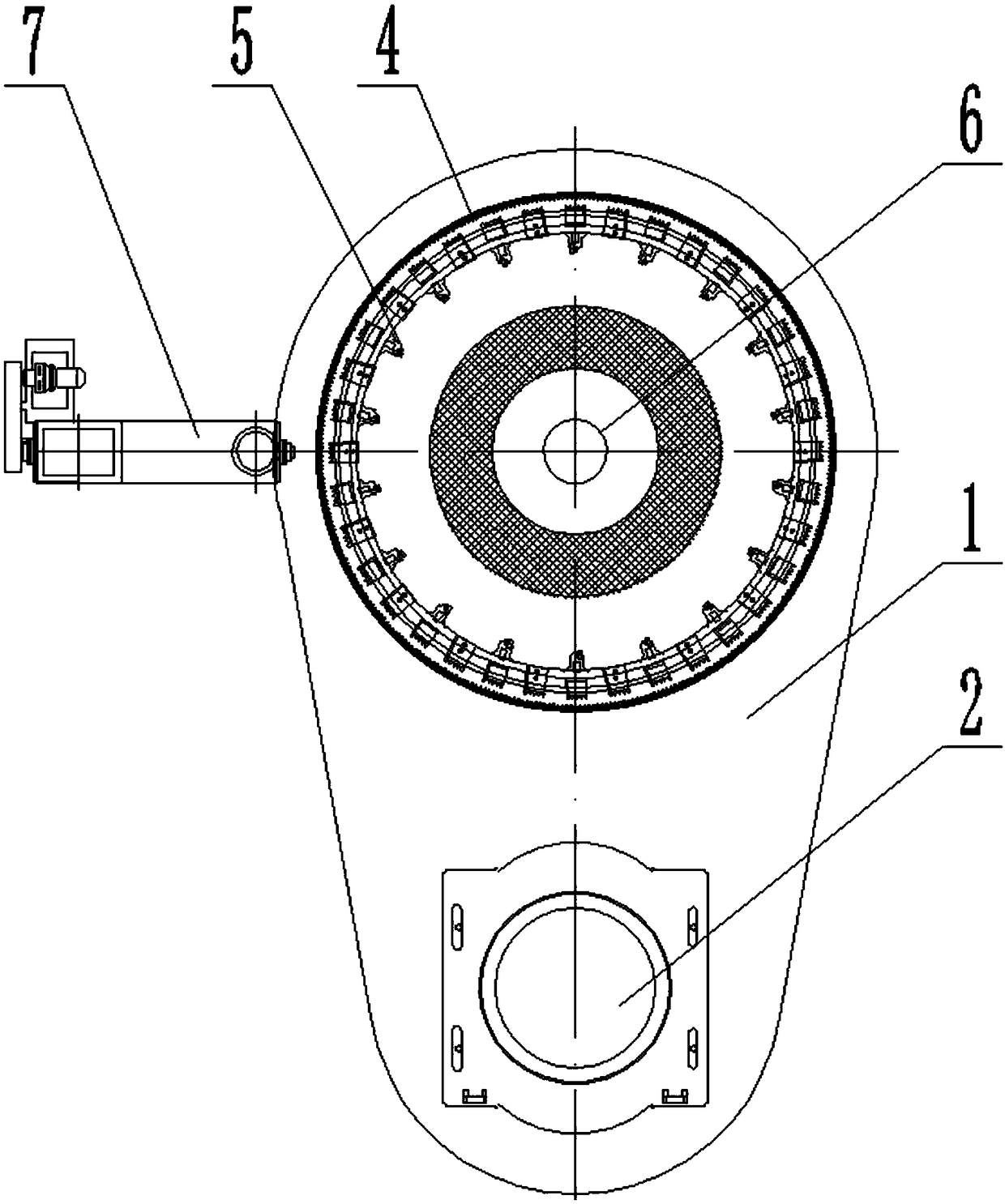

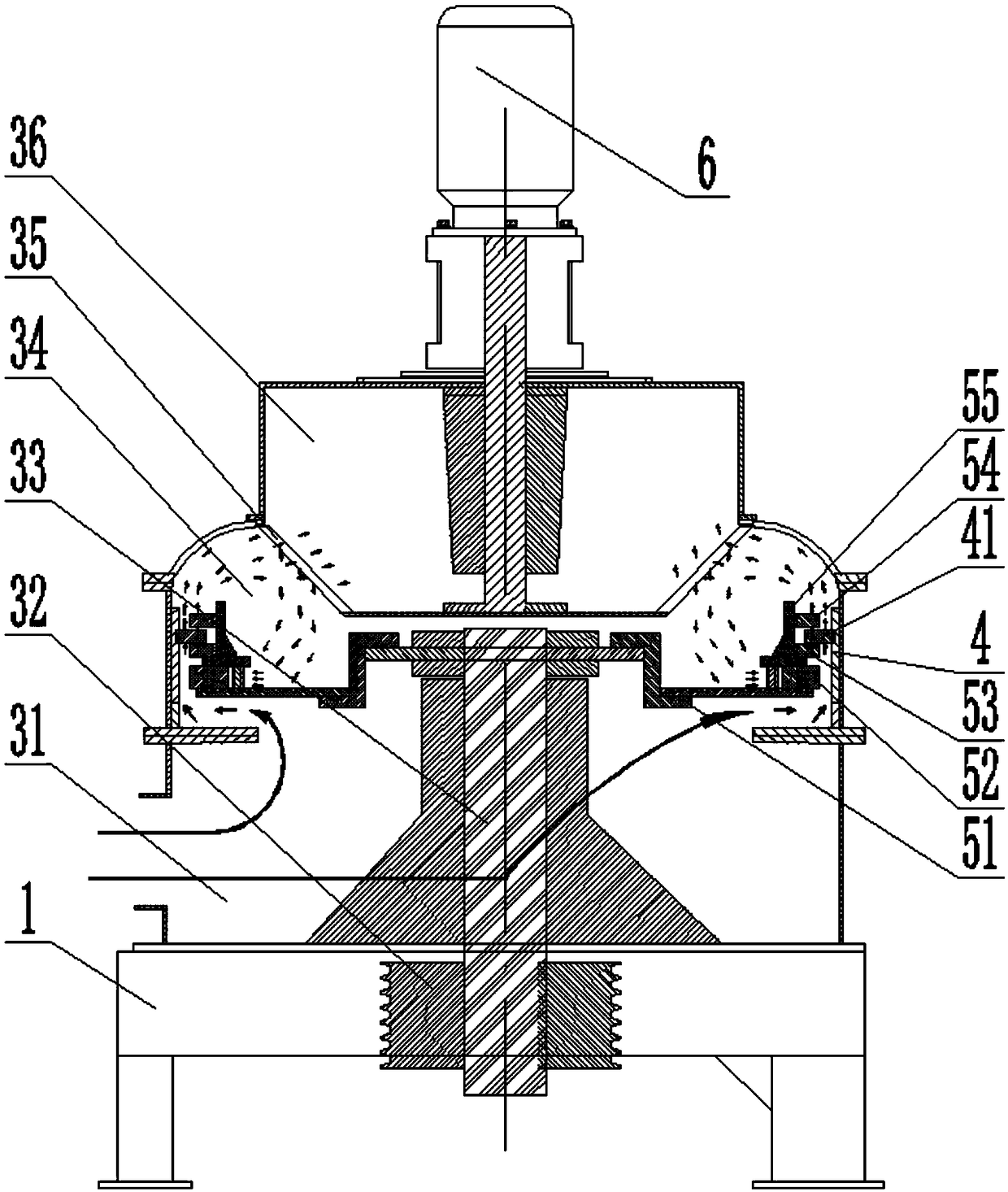

[0032] Such as figure 1 , figure 2 with image 3 As shown, a multi-group hammer ultrafine pulverizer mainly includes a base 1, and the base 1 is provided with a pulverizer main body and a power transmission system, and the pulverizer main body 3 is sequentially settling chamber 31, crushing chamber 34 and discharge chamber 36 , the crushing chamber 34 includes a crushing disc 5 arranged on the main shaft 33 of the crushing machine and an inner ring gear 4 arranged on the inner wall of the shell of the crushing chamber 34 . The main body 3 of the pulverizer is provided with an air inlet, a material inlet, and a material outlet, and a feeding auger 7 is installed at the material inlet. The main body 3 of the pulverizer is provided with a pulverizing disc 5 and an inner ring gear 4 for pulverizing materials. There is also a classifying wheel 35 for sieving materials. The materials to be crushed are sent into the feed port of the main body 3 of the pulverizer through the feedin...

Embodiment 2

[0041] The main structure of this embodiment is similar to that of Embodiment 1, and the usage method and principle are similar, the difference is that: Image 6 with Figure 7 As shown, the large plate 51 includes a fixed plate 511 , a stepped plate 512 and a connecting plate 513 . The fixed disk 511, the stepped disk 512 and the connecting disk 513 are all annular, the inner circle of the fixed disk 511 is fixed on the main shaft 33, the outer circle of the fixed disk 511 is connected with the inner circle of the stepped disk 512, and the outer circle of the stepped disk 512 is connected with the inner circle of the stepped disk 512. The inner circle of the disc 513 is connected, and the outer circle of the connecting disc 513 is provided with a movable hammer; the height of the inner circle of the stepped disc 512 in the vertical direction is higher than the outer circle of the stepped disc 512, and the preferred vertical direction of the stepped disc 512 is The section is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com